Circuit-break locator for the holidays

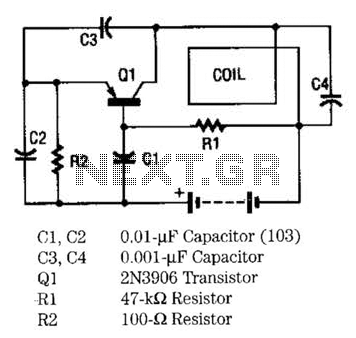

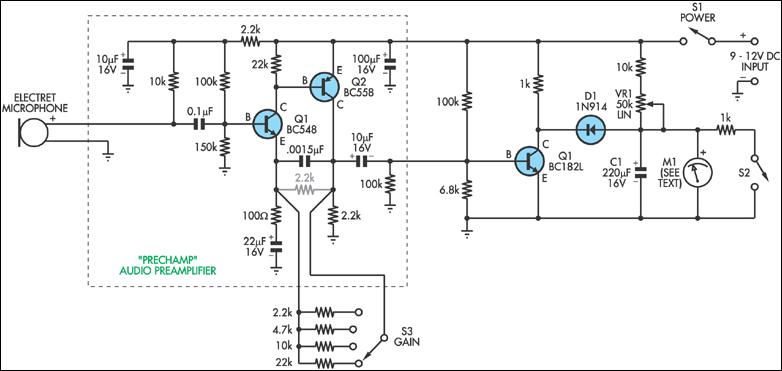

The circuit depicted here is designed to identify defective bulbs by capacitively sensing the electric fields they generate. To understand its operation, consider a string of bulbs with an open-circuited filament, referred to in the schematic as the String Under Test. The intact filaments on either side of the burned-out bulb create continuous circuits from the AC supply. The AC voltage differential between wires leading to any functional bulb is zero, while the differential between the connections to the defective bulb will be the full 110 V. The presence of 110 V AC on a wire generates substantial electrostatic fields that can be easily detected through plastic insulation. The high-impedance CMOS inputs of XOR U1 can achieve this detection. Resistors R1 and R2 not only provide operating power to the circuit but also effectively position U1 midway between the AC supply rails. This results in equal-amplitude (160 V peak-to-peak) but opposite-phase voltage differentials between U1 and both AC rails. R4 and C1 reference U1 pin 2 to AC neutral, while R2 and the Test electrode are utilized to capacitively probe the voltages present in the wires of the String Under Test. U1 operates as a phase-sensitive detector of these AC voltages. When the Test electrode is positioned near point A, which is continuous with the hot rail, the signals at U1's inputs will have opposing phases. One input will be high (logic one) when the other is low (logic zero), causing XOR U1 to maintain pin 3 high, resulting in D2 glowing. If the probe is moved to points B or C, the same phase relationship continues, and D2 remains illuminated. However, if the probe approaches point D, the sensed phase will reverse due to the circuit break located between D and the hot rail. This induces neutral phase voltage in the probe, causing pin 3 to go low, extinguishing D2, lighting D1, and indicating the defective filament. The faulty lamp can then be replaced. In practice, when searching for a bad bulb starting from the power plug end of the String Under Test, the initial phase relationship is arbitrary, leading to either D1 or D2 glowing. In any case, it is the sudden change in which LED is lit as the probe is moved along the String Under Test that signals the detection of the broken filament.

The circuit operates by utilizing capacitive coupling to detect voltage differentials across the string of bulbs. The use of a high-impedance CMOS XOR gate (U1) allows for sensitive detection of phase changes without drawing significant current from the circuit under test. The resistors R1 and R2 play a crucial role in maintaining the operational state of U1, ensuring that it remains responsive to changes in voltage. The capacitive probe mechanism, facilitated by the Test electrode, allows for non-invasive testing, making it practical for identifying issues without needing to disconnect the bulbs.

The design of the circuit ensures that it can operate effectively in environments where the AC supply is present, as the capacitive sensing mechanism can detect the electric fields even through insulation. This characteristic is particularly useful for maintenance and troubleshooting in lighting systems where access to wiring may be limited. The visual indicators, D1 and D2, provide immediate feedback to the user, allowing for quick identification of defective components. The circuit's response to the position of the probe provides a clear and intuitive method for locating faults within the string of bulbs, streamlining the process of maintenance and ensuring that faulty bulbs can be replaced swiftly.The circuit illustrated here comes to the rescue by sniffing out defective bulbs by capacitively sensing the electric fields they produce ( see the figure ). To understand how it works, consider a string of bulbs with an opencircuited filament, labeled in the schematic as String Under Test.

The intact filaments on either side of the burned-out bulb complete continuous circuits from the ac supply all the way around to the opposite ends of the broken filament. The ac voltage differential between wires leading to any intact bulb is zero, but the differential between the connections to the defective bulb will be the full 110 V. The presence of 110 V ac on a wire produces large electrostatic fields that are easily detected through plastic insulation.

The high-impedance CMOS inputs of XOR U1 can do just that. Resistors R1 and R2, in addition to delivering operating power to the circuit, effectively suspend U1 midway between the ac supply rails. Thus, equal-amplitude (160 V p-p) but opposite-phase voltage differentials will exist between U1 and both ac rails.

R4 and C1 reference U1 pin 2 to ac neutral, while R2 and the Test electrode are used to capacitively probe the voltages present in the wires of the String Under Test. U1 then performs as a phase-sensitive detector of those ac voltages. Suppose the Test electrode is held close to point A. Because A is continuous with the hot rail, the signals at U1`s inputs will have opposing phases. One input will be high (logic one) whenever the other is low (logic zero). This causes XOR U1 to hold pin 3 high, so D2 glows. If the probe is moved to points B or C, the same phase relationship will persist and D2 will still glow.

But if the probe is brought near D, the sensed phase will reverse because the circuit break lies between D and the hot rail. Consequently, neutral phase voltage is induced in the probe. Pin 3 will therefore go low, extinguishing D2, lighting D1, and thus designating the offending filament.

The defective lamp then is replaced. In actual use, when the bad-bulb search is commenced near the powerplug end of the String Under Test, the initial phase relationship will be arbitrary, so either D1 or D2 may glow. In either case, it`s the sudden change in which a LED is lit as the probe is moved along the String Under Test that indicates when the broken filament has been found.

🔗 External reference

The circuit operates by utilizing capacitive coupling to detect voltage differentials across the string of bulbs. The use of a high-impedance CMOS XOR gate (U1) allows for sensitive detection of phase changes without drawing significant current from the circuit under test. The resistors R1 and R2 play a crucial role in maintaining the operational state of U1, ensuring that it remains responsive to changes in voltage. The capacitive probe mechanism, facilitated by the Test electrode, allows for non-invasive testing, making it practical for identifying issues without needing to disconnect the bulbs.

The design of the circuit ensures that it can operate effectively in environments where the AC supply is present, as the capacitive sensing mechanism can detect the electric fields even through insulation. This characteristic is particularly useful for maintenance and troubleshooting in lighting systems where access to wiring may be limited. The visual indicators, D1 and D2, provide immediate feedback to the user, allowing for quick identification of defective components. The circuit's response to the position of the probe provides a clear and intuitive method for locating faults within the string of bulbs, streamlining the process of maintenance and ensuring that faulty bulbs can be replaced swiftly.The circuit illustrated here comes to the rescue by sniffing out defective bulbs by capacitively sensing the electric fields they produce ( see the figure ). To understand how it works, consider a string of bulbs with an opencircuited filament, labeled in the schematic as String Under Test.

The intact filaments on either side of the burned-out bulb complete continuous circuits from the ac supply all the way around to the opposite ends of the broken filament. The ac voltage differential between wires leading to any intact bulb is zero, but the differential between the connections to the defective bulb will be the full 110 V. The presence of 110 V ac on a wire produces large electrostatic fields that are easily detected through plastic insulation.

The high-impedance CMOS inputs of XOR U1 can do just that. Resistors R1 and R2, in addition to delivering operating power to the circuit, effectively suspend U1 midway between the ac supply rails. Thus, equal-amplitude (160 V p-p) but opposite-phase voltage differentials will exist between U1 and both ac rails.

R4 and C1 reference U1 pin 2 to ac neutral, while R2 and the Test electrode are used to capacitively probe the voltages present in the wires of the String Under Test. U1 then performs as a phase-sensitive detector of those ac voltages. Suppose the Test electrode is held close to point A. Because A is continuous with the hot rail, the signals at U1`s inputs will have opposing phases. One input will be high (logic one) whenever the other is low (logic zero). This causes XOR U1 to hold pin 3 high, so D2 glows. If the probe is moved to points B or C, the same phase relationship will persist and D2 will still glow.

But if the probe is brought near D, the sensed phase will reverse because the circuit break lies between D and the hot rail. Consequently, neutral phase voltage is induced in the probe. Pin 3 will therefore go low, extinguishing D2, lighting D1, and thus designating the offending filament.

The defective lamp then is replaced. In actual use, when the bad-bulb search is commenced near the powerplug end of the String Under Test, the initial phase relationship will be arbitrary, so either D1 or D2 may glow. In either case, it`s the sudden change in which a LED is lit as the probe is moved along the String Under Test that indicates when the broken filament has been found.

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713