Closed-Loop Automatic Power Control for RF Applications

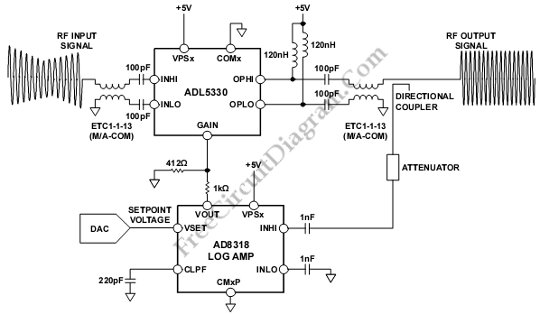

This is a circuit for Closed-Loop Automatic Power Control for RF Applications. The circuit utilizes a log detector (AD8318) and a variable gain amplifier (VGA) (ADL5330).

The Closed-Loop Automatic Power Control (APC) circuit is designed to maintain a consistent output power level in RF applications, such as transmitters and amplifiers. The system operates by continuously measuring the output power using the log detector AD8318, which provides a logarithmic representation of the input power level. This feature allows for a wide dynamic range and precise power level detection, making it suitable for applications where power fluctuations can significantly impact performance.

The output from the AD8318 is fed into the variable gain amplifier (VGA) ADL5330, which adjusts the gain based on the detected power level. By varying the gain, the VGA can compensate for any changes in output power, ensuring that the desired output level is maintained. The feedback loop formed by the log detector and the VGA allows for rapid adjustments in response to changes in the input signal, providing stable operation under varying conditions.

In terms of implementation, the circuit typically includes additional components such as resistors and capacitors to filter and stabilize the signals. Proper layout and design considerations are crucial to minimize noise and ensure reliable operation, particularly in high-frequency applications. The power supply for the components should also be carefully regulated to avoid introducing additional variations in the output power.

Overall, this closed-loop APC circuit is essential for achieving optimal performance in RF systems, allowing for efficient power management and improved signal integrity.This is a circuit of Closed-Loop Automatic Power Control for RF Applications. The circuit uses a log detector (AD8318) and a VGA (ADL5330). This circuit has a. 🔗 External reference

The Closed-Loop Automatic Power Control (APC) circuit is designed to maintain a consistent output power level in RF applications, such as transmitters and amplifiers. The system operates by continuously measuring the output power using the log detector AD8318, which provides a logarithmic representation of the input power level. This feature allows for a wide dynamic range and precise power level detection, making it suitable for applications where power fluctuations can significantly impact performance.

The output from the AD8318 is fed into the variable gain amplifier (VGA) ADL5330, which adjusts the gain based on the detected power level. By varying the gain, the VGA can compensate for any changes in output power, ensuring that the desired output level is maintained. The feedback loop formed by the log detector and the VGA allows for rapid adjustments in response to changes in the input signal, providing stable operation under varying conditions.

In terms of implementation, the circuit typically includes additional components such as resistors and capacitors to filter and stabilize the signals. Proper layout and design considerations are crucial to minimize noise and ensure reliable operation, particularly in high-frequency applications. The power supply for the components should also be carefully regulated to avoid introducing additional variations in the output power.

Overall, this closed-loop APC circuit is essential for achieving optimal performance in RF systems, allowing for efficient power management and improved signal integrity.This is a circuit of Closed-Loop Automatic Power Control for RF Applications. The circuit uses a log detector (AD8318) and a VGA (ADL5330). This circuit has a. 🔗 External reference