cnc laser buildlog

The recent Epilog Laser Challenge on Instructables.com inspired the idea of constructing a low-cost CNC laser. The engraver offered as a prize has a retail price of approximately $8,000, resulting in a significant tax burden. It is believed that a larger, more powerful machine could be assembled for less than the tax amount. The Epilog Zing 16 operates at 30W with a working area of 16" x 20". The challenge lies in achieving a similar capability for under $1,000. It is acknowledged that a substantial portion of the value from Epilog derives from their software, safety features, support, and warranty, making the challenge somewhat imbalanced. The approach to this project will be systematic to minimize unnecessary expenses and time. The design is intended to be highly scalable for more powerful lasers. The initial phase will utilize the lowest power laser as a proof of concept. Previous experience in building several successful CNC routers provides confidence in the mechanical aspects, while the laser components present new challenges. There is considerable uncertainty regarding the Chinese parts, and efforts will be made to clarify these issues throughout the process.

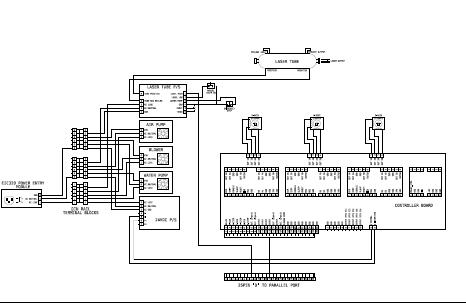

The proposed CNC laser system aims to create an affordable, scalable solution for laser engraving and cutting. The design will incorporate a basic frame structure, likely constructed from aluminum extrusions or steel tubing, ensuring rigidity and stability during operation. The motion system will utilize stepper motors coupled with precision linear rails or lead screws to achieve accurate positioning of the laser head.

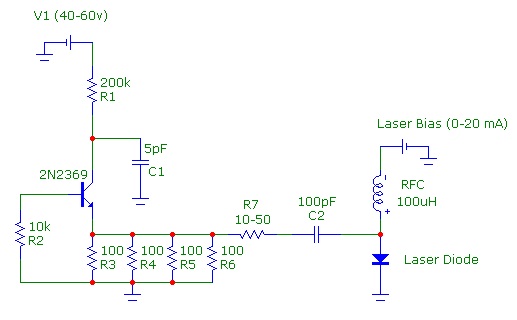

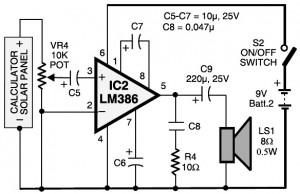

The laser source will be selected based on power requirements and budget constraints, with options ranging from CO2 lasers to diode lasers, depending on the intended applications. A cooling system, such as a water chiller or air cooling, will be necessary to maintain optimal operating temperatures for the laser module, ensuring longevity and consistent performance.

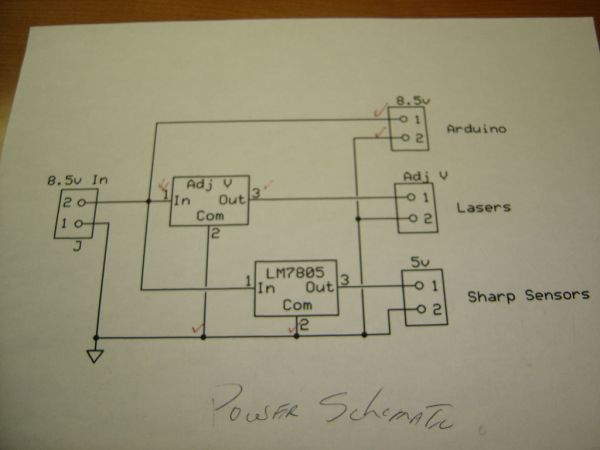

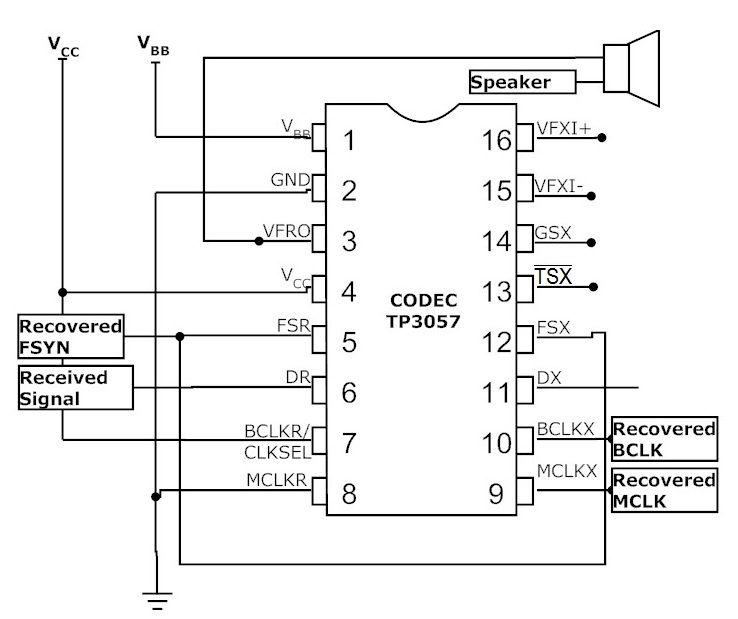

The control system will be based on an open-source platform, such as GRBL or Mach3, which allows for easy integration with various hardware components. This system will handle the communication between the computer and the CNC laser, interpreting G-code commands to control the movement of the laser head and the firing of the laser itself. A user-friendly interface will be developed to facilitate ease of use, allowing users to upload designs and adjust settings for different materials.

Safety features will be integrated into the design, including an enclosure to contain fumes and debris generated during operation, as well as interlock systems to prevent operation when the enclosure is open. Additionally, a fire suppression system may be considered to address potential hazards associated with the laser cutting process.

Overall, the project will focus on balancing cost, functionality, and safety, with the goal of delivering a reliable CNC laser system that meets the needs of hobbyists and small businesses alike. The iterative development process will allow for adjustments and improvements based on testing and user feedback, ultimately leading to a robust and effective laser engraving solution.The recent Epilog Laser Challenge at Instructables. com got me thinking about building a low cost CNC laser. The engrave r they had as the prize had a list price of about $8, 000. The income tax on that would be quite a lot. I thought a larger more powerful machine could easily be built for less than the amount you would have to pay for the tax. The Epilog Zing 16 is 30W with an area of 16" x 20". Try to beat that for less than $1, 000. I understand that a huge part of what you get from Epilog is software, safety, support and a guarantee, so it is not a really fair challenge. I want to approach this in a very serialized manner to prevent wasting excess money or time. The design should be very scalable to more powerful lasers. I will start with the lowest power laser as a proof of concept. I have built several successful CNC routers from scratch so I feel confident on the mechanics. The laser issues will all be new. There is a lot of mystery on the Chinese parts. I will try to fill in all I can along the way. 🔗 External reference

The proposed CNC laser system aims to create an affordable, scalable solution for laser engraving and cutting. The design will incorporate a basic frame structure, likely constructed from aluminum extrusions or steel tubing, ensuring rigidity and stability during operation. The motion system will utilize stepper motors coupled with precision linear rails or lead screws to achieve accurate positioning of the laser head.

The laser source will be selected based on power requirements and budget constraints, with options ranging from CO2 lasers to diode lasers, depending on the intended applications. A cooling system, such as a water chiller or air cooling, will be necessary to maintain optimal operating temperatures for the laser module, ensuring longevity and consistent performance.

The control system will be based on an open-source platform, such as GRBL or Mach3, which allows for easy integration with various hardware components. This system will handle the communication between the computer and the CNC laser, interpreting G-code commands to control the movement of the laser head and the firing of the laser itself. A user-friendly interface will be developed to facilitate ease of use, allowing users to upload designs and adjust settings for different materials.

Safety features will be integrated into the design, including an enclosure to contain fumes and debris generated during operation, as well as interlock systems to prevent operation when the enclosure is open. Additionally, a fire suppression system may be considered to address potential hazards associated with the laser cutting process.

Overall, the project will focus on balancing cost, functionality, and safety, with the goal of delivering a reliable CNC laser system that meets the needs of hobbyists and small businesses alike. The iterative development process will allow for adjustments and improvements based on testing and user feedback, ultimately leading to a robust and effective laser engraving solution.The recent Epilog Laser Challenge at Instructables. com got me thinking about building a low cost CNC laser. The engrave r they had as the prize had a list price of about $8, 000. The income tax on that would be quite a lot. I thought a larger more powerful machine could easily be built for less than the amount you would have to pay for the tax. The Epilog Zing 16 is 30W with an area of 16" x 20". Try to beat that for less than $1, 000. I understand that a huge part of what you get from Epilog is software, safety, support and a guarantee, so it is not a really fair challenge. I want to approach this in a very serialized manner to prevent wasting excess money or time. The design should be very scalable to more powerful lasers. I will start with the lowest power laser as a proof of concept. I have built several successful CNC routers from scratch so I feel confident on the mechanics. The laser issues will all be new. There is a lot of mystery on the Chinese parts. I will try to fill in all I can along the way. 🔗 External reference