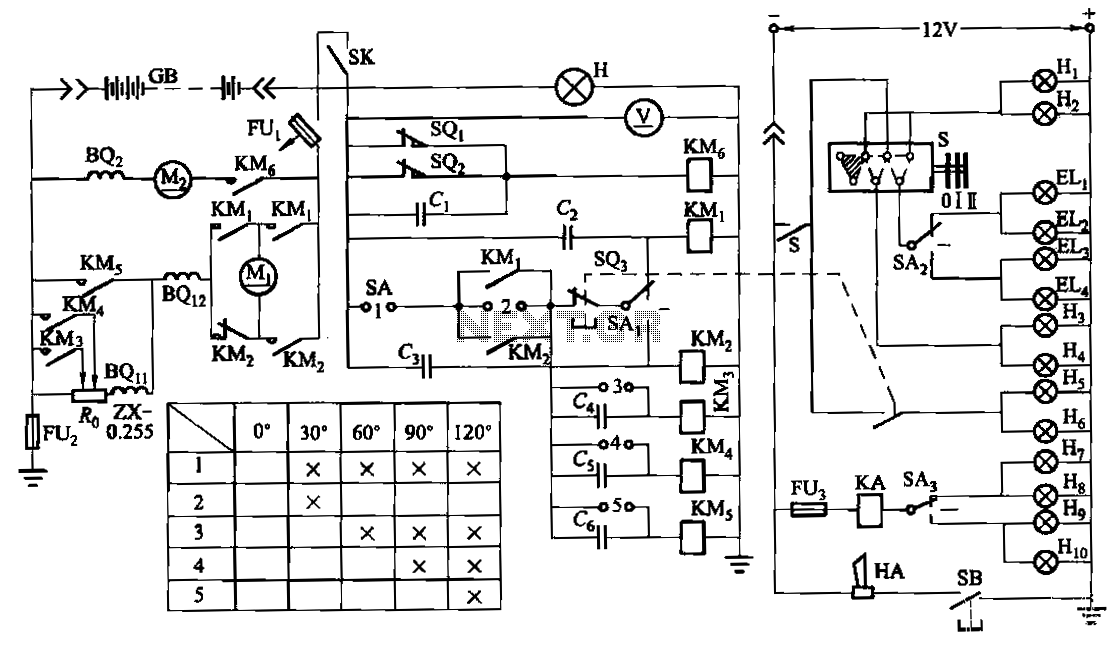

CPD type forklift battery control circuit

The forklift electric drive system comprises two DC series motors and associated control equipment. A 4.5 kW electric motor drives the vehicle through a mechanical transmission mechanism, enabling forward and backward movement of the forklift. A 6 kW pump motor operates a hydraulic mechanism that controls mast tilting, lifting, and forward movement of appendages. The system includes limit switches SQ1 and SQ2 for the pump. In the event of an emergency brake activation, the limit switch opens, causing the normally closed contacts to disconnect, which releases contactors KM1 or KM2 and leads to the stalling of motor M1.

The forklift electric drive system is designed to provide reliable and efficient operation for material handling tasks. The two DC series motors are utilized for their high starting torque, making them suitable for the heavy loads typically handled by forklifts. The 4.5 kW drive motor (M1) is responsible for propelling the forklift, with its output connected to a mechanical transmission that translates the motor's rotational force into linear motion. This configuration allows for smooth acceleration and deceleration during operation, enhancing the operator's control over the vehicle.

The 6 kW pump motor (M2) is specifically dedicated to powering the hydraulic system, which is essential for the operation of the forklift's mast and appendages. The hydraulic mechanism allows for precise control of mast movements, such as tilting and lifting, which are critical for loading and unloading materials. The pump's output is regulated by limit switches SQ1 and SQ2, which ensure that the hydraulic system operates within safe parameters, preventing overextension or damage to the hydraulic components.

In terms of safety, the system incorporates an emergency brake feature that is activated through a limit switch. When the emergency brake is engaged, the limit switch opens the normally closed contacts, effectively cutting power to the drive motor and releasing the contactors. This safety mechanism is crucial for preventing unintended movement of the forklift, particularly in emergency situations.

Overall, this electric drive system for the forklift is engineered to deliver robust performance while prioritizing safety and operational efficiency. The integration of DC series motors with hydraulic control mechanisms exemplifies a well-thought-out design tailored for the demands of material handling environments.Forklift electric drive system consists of two DC series motors and control equipment. 4. 5kW electric motor driving through a mechanical transmission mechanism Mi, driving forklifts for forward and backward travel. 6.skW pump motor M2 machine after machine driven by a hydraulic mechanism mast tilting, lifting or forward movement and appendages. Figure, SQi, SQ2 to pump limit switches. When the emergency brake, limit switch so. The normally closed contacts disconnect, contactors KMi or KMz release, motor Mi stall.

The forklift electric drive system is designed to provide reliable and efficient operation for material handling tasks. The two DC series motors are utilized for their high starting torque, making them suitable for the heavy loads typically handled by forklifts. The 4.5 kW drive motor (M1) is responsible for propelling the forklift, with its output connected to a mechanical transmission that translates the motor's rotational force into linear motion. This configuration allows for smooth acceleration and deceleration during operation, enhancing the operator's control over the vehicle.

The 6 kW pump motor (M2) is specifically dedicated to powering the hydraulic system, which is essential for the operation of the forklift's mast and appendages. The hydraulic mechanism allows for precise control of mast movements, such as tilting and lifting, which are critical for loading and unloading materials. The pump's output is regulated by limit switches SQ1 and SQ2, which ensure that the hydraulic system operates within safe parameters, preventing overextension or damage to the hydraulic components.

In terms of safety, the system incorporates an emergency brake feature that is activated through a limit switch. When the emergency brake is engaged, the limit switch opens the normally closed contacts, effectively cutting power to the drive motor and releasing the contactors. This safety mechanism is crucial for preventing unintended movement of the forklift, particularly in emergency situations.

Overall, this electric drive system for the forklift is engineered to deliver robust performance while prioritizing safety and operational efficiency. The integration of DC series motors with hydraulic control mechanisms exemplifies a well-thought-out design tailored for the demands of material handling environments.Forklift electric drive system consists of two DC series motors and control equipment. 4. 5kW electric motor driving through a mechanical transmission mechanism Mi, driving forklifts for forward and backward travel. 6.skW pump motor M2 machine after machine driven by a hydraulic mechanism mast tilting, lifting or forward movement and appendages. Figure, SQi, SQ2 to pump limit switches. When the emergency brake, limit switch so. The normally closed contacts disconnect, contactors KMi or KMz release, motor Mi stall.