Custom Fan Controller

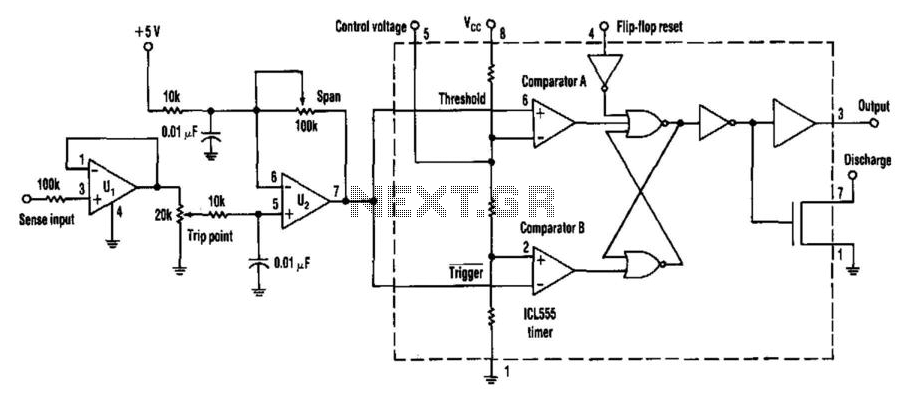

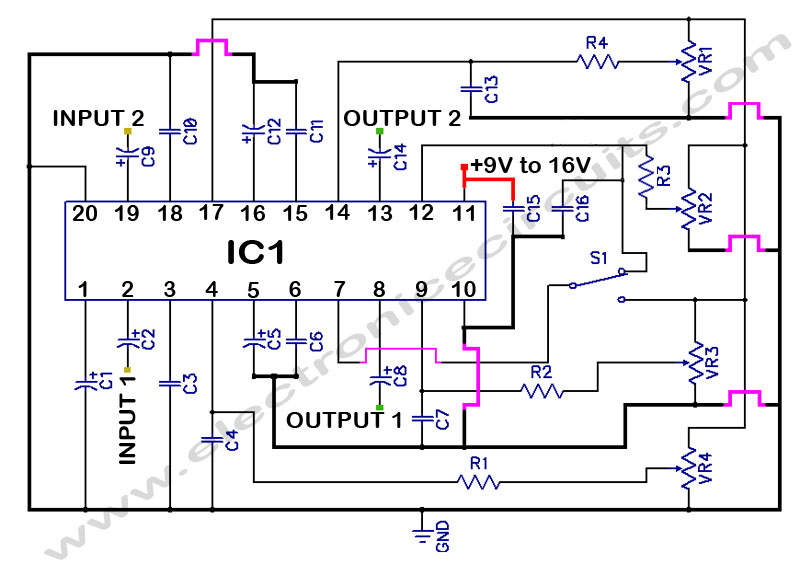

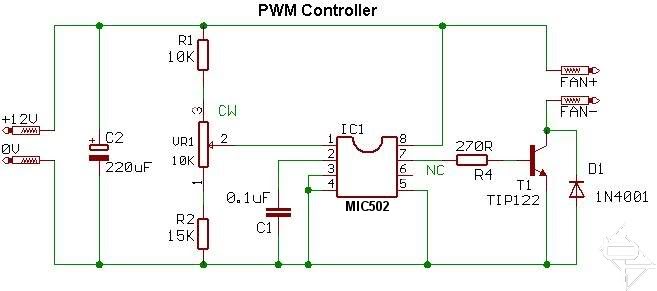

This circuit diagram illustrates the design for each individual channel. A modification was made by replacing the 0.1 µF timing capacitor with a 100 pF capacitor to enhance performance. The original 0.1 µF capacitor caused the fans to produce a growling noise when operating at lower speeds, which was mitigated by the introduction of the 100 pF capacitor. The circuit employs a variable resistor to adjust the fan speed, which can be integrated on the board (as indicated by light blue squares with a slotted white screw at the center) or can be connected to a remote panel-mounted potentiometer equipped with a knob.

This circuit diagram is designed for controlling the speed of fans in various electronic applications. The key component in this setup is the variable resistor, which serves as a potentiometer to adjust the voltage supplied to the fan motor. This voltage control allows for smooth operation across a range of speeds, providing flexibility in cooling performance based on thermal requirements.

In the modified circuit, the timing capacitor plays a crucial role in determining the response time of the fan speed adjustment. By replacing the 0.1 µF capacitor with a 100 pF capacitor, the circuit achieves a more stable operation without the undesirable noise associated with slower fan speeds. This change is particularly beneficial in environments where noise reduction is essential, such as in home theaters or quiet office spaces.

The design also offers the option for user interaction through manual control. The variable resistor can be mounted directly on the circuit board for straightforward adjustments or can be configured as a remote control unit, allowing users to adjust the fan speed from a distance. This versatility caters to different user preferences and installation scenarios, enhancing the overall usability of the circuit.

When implementing this circuit, it is important to ensure that all components are rated appropriately for the application, particularly the fan motor and the variable resistor, to prevent overheating or electrical failure. Proper thermal management should also be considered, as fan speed control is often critical in maintaining optimal operating temperatures for electronic devices. Overall, this circuit provides an effective solution for fan speed regulation while minimizing noise and offering user-friendly controls.This is the circuit diagram for each individual channel; Note: I replaced the 0. 1 uF timing capacitor with a 100 pF capacitor for better operation, with the 0. 1 uF capacitor in place, the fans would growl when turned down to slower speeds and the 100 pF capacitor resolved that problem. This is the circuit diagram for each individual channel; Note: I replaced the 0. 1 uF timing capacitor with a 100 pF capacitor for better operation, with the 0. 1 uF capacitor in place, the fans would growl when turned down to slower speeds and the 100 pF capacitor resolved that problem. wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly.

wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly. wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly.

It uses a variable resistor to control the fan speed this can either be on-board (as in my case; notice the light blue squares with the slotted white screw at the center) or with a remote (panel mount) potentiometer with a knob. 🔗 External reference

This circuit diagram is designed for controlling the speed of fans in various electronic applications. The key component in this setup is the variable resistor, which serves as a potentiometer to adjust the voltage supplied to the fan motor. This voltage control allows for smooth operation across a range of speeds, providing flexibility in cooling performance based on thermal requirements.

In the modified circuit, the timing capacitor plays a crucial role in determining the response time of the fan speed adjustment. By replacing the 0.1 µF capacitor with a 100 pF capacitor, the circuit achieves a more stable operation without the undesirable noise associated with slower fan speeds. This change is particularly beneficial in environments where noise reduction is essential, such as in home theaters or quiet office spaces.

The design also offers the option for user interaction through manual control. The variable resistor can be mounted directly on the circuit board for straightforward adjustments or can be configured as a remote control unit, allowing users to adjust the fan speed from a distance. This versatility caters to different user preferences and installation scenarios, enhancing the overall usability of the circuit.

When implementing this circuit, it is important to ensure that all components are rated appropriately for the application, particularly the fan motor and the variable resistor, to prevent overheating or electrical failure. Proper thermal management should also be considered, as fan speed control is often critical in maintaining optimal operating temperatures for electronic devices. Overall, this circuit provides an effective solution for fan speed regulation while minimizing noise and offering user-friendly controls.This is the circuit diagram for each individual channel; Note: I replaced the 0. 1 uF timing capacitor with a 100 pF capacitor for better operation, with the 0. 1 uF capacitor in place, the fans would growl when turned down to slower speeds and the 100 pF capacitor resolved that problem. This is the circuit diagram for each individual channel; Note: I replaced the 0. 1 uF timing capacitor with a 100 pF capacitor for better operation, with the 0. 1 uF capacitor in place, the fans would growl when turned down to slower speeds and the 100 pF capacitor resolved that problem. wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly.

wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly. wow, that`s impressive. I have almost no experience with circuitry on that level, so that wouldn`t work too well for me (how do you control that then btw, cause if it`s a knob of some sort, I may look into something like that, how hard would it be to learn) That would be real close to what I`m looking for, if you could add manual knobs, but If not the Zalman would work perfectly.

It uses a variable resistor to control the fan speed this can either be on-board (as in my case; notice the light blue squares with the slotted white screw at the center) or with a remote (panel mount) potentiometer with a knob. 🔗 External reference