Diac Applications

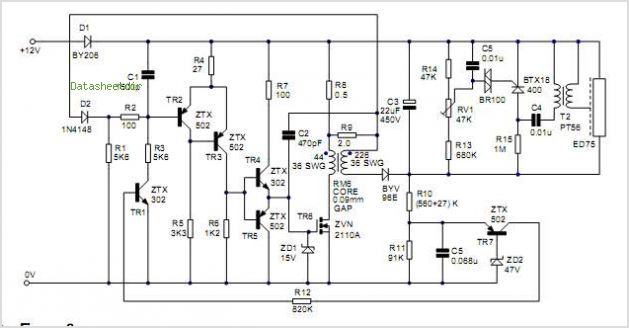

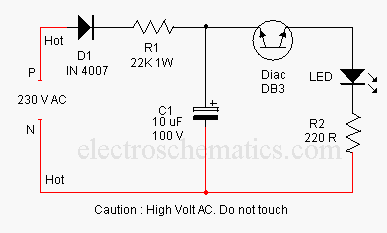

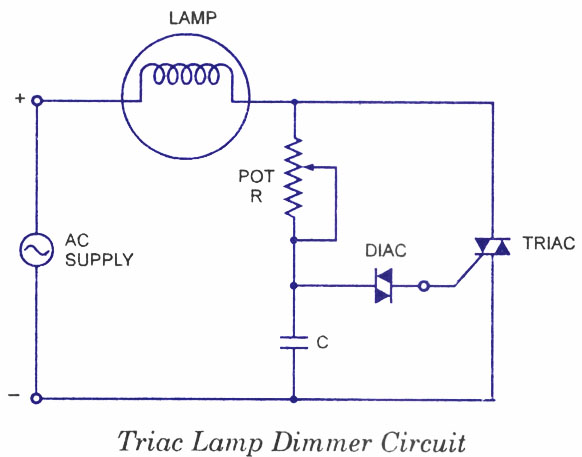

Diacs are widely used as triggering devices in triac phase control circuits due to their symmetrical bidirectional switching characteristics. These circuits are employed in applications such as lamp dimmers, heat control, and universal motor speed control. While a triac can be activated using a simple resistive triggering circuit, triggering devices are generally placed in series with the gates of SCRs and triacs to ensure reliable and rapid triggering. The diac is the most commonly used triggering device for the triac. An example of this can be seen in a circuit where a triac is controlled by an R-C phase-shift network and a diac, which serves as a simple lamp dimmer. The conduction angle of the triac can be adjusted by varying the potentiometer R; the longer the triac conducts, the brighter the lamp will be. The diac remains in an open-circuit state until the voltage across the capacitor exceeds its breakover or switching voltage, as well as the gate trigger voltage required for the triac. A typical diac-triac circuit used for smooth control of AC power to a heater is also described. In this configuration, the capacitor C1 is placed in series with a choke L across the triac, which slows the voltage rise across the device during the off-state. The resistor R4, connected across the diac, ensures smooth control at all settings of the potentiometer R2. Adjusting the potentiometer R2 modifies the conduction angle of the triac, resulting in larger output from the heater as the triac conducts for a longer duration. This setup enables smooth regulation of heat output from the heater.

The use of diacs in triac control circuits capitalizes on their unique ability to switch on and off at precise voltage levels, making them ideal for applications requiring fine control over power delivery. In a typical lamp dimmer circuit, the diac is connected to a capacitor and a resistor network, which together create a phase delay. As the AC voltage rises, the capacitor charges until it reaches the diac's breakover voltage. At this point, the diac conducts, triggering the triac and allowing current to flow to the load (in this case, a lamp). The conduction angle is directly proportional to the charge time of the capacitor, which can be adjusted using the potentiometer.

In heater control circuits, the configuration is similar, but with additional components such as inductors (chokes) to manage the current flow and reduce voltage spikes during switching. The choke helps to smooth out the current, preventing sudden changes that could damage the triac or the load. The resistor across the diac ensures that it remains responsive to changes in the potentiometer setting, allowing for a more consistent output regardless of the position of the control knob.

Overall, the integration of diacs in triac circuits enhances their performance, providing a reliable solution for applications that require variable power control, such as lighting and heating systems. The design considerations, including component selection and layout, are crucial for achieving optimal performance and ensuring the longevity of the circuit.The diacs, because of their symmetrical bidirectional switching characteristics, are widely used as triggering devices in triac phase control circuits em ployed for lamp dimmer, heat control, universal motor speed control etc. Although a triac may be fired into the conducting state by a simple resistive triggering circuit, but triggering devices

are typically placed in series with the gates of SCRs and triacs as they give reliable and fast triggering. Diac is the most popular triggering device for the triac. This is illustrated in the following applications. The circuit for a triac controlled by an R-C phase-shift network and a diac is given in figure. This circuit is an example of a simple lamp dimmer. The triac conduction angle is adjusted by adjusting the potentiometer R. The longer the triac conducts, the brighter the lamp will be. The diac acts like an open-circuit until the voltage across the capacitor exceeds its breakover or switching voltage (and the triac`s required gate trigger voltage).

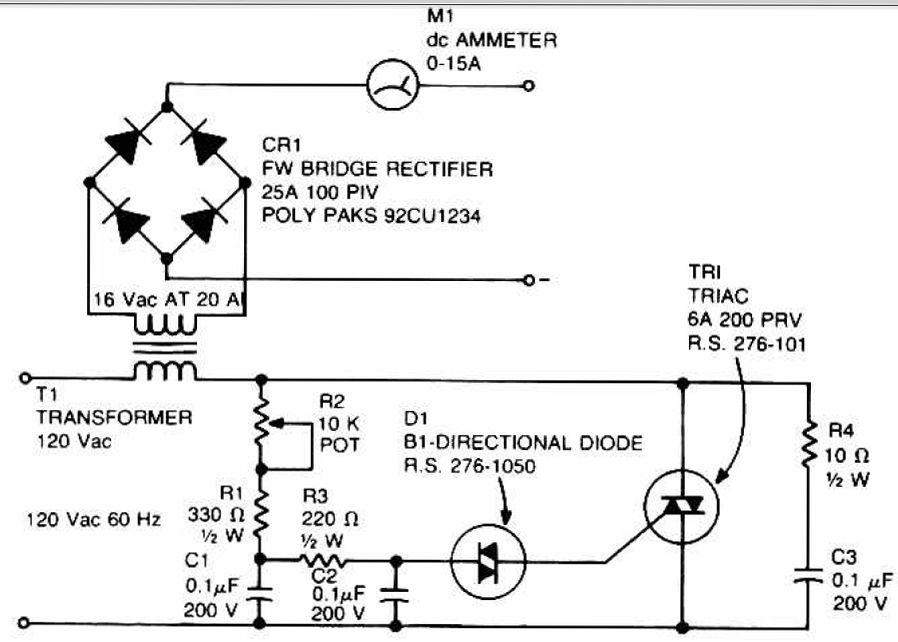

A typical diac-triac circuit used for smooth control of ac power to a heater is shown in figure. The capacitor C1 in series with choke L across the triac slows-up the voltage rise across the device during off-state. The resistor R4 across the diac ensures smooth control at all positions of potentiometer R2. The triac conduction angle is adjusted by adjusting the potentiometer R2. The longer the triac conducts, the larger the output will be from the heater. Thus a smooth control of the heat output from the heater is obtained. 🔗 External reference

The use of diacs in triac control circuits capitalizes on their unique ability to switch on and off at precise voltage levels, making them ideal for applications requiring fine control over power delivery. In a typical lamp dimmer circuit, the diac is connected to a capacitor and a resistor network, which together create a phase delay. As the AC voltage rises, the capacitor charges until it reaches the diac's breakover voltage. At this point, the diac conducts, triggering the triac and allowing current to flow to the load (in this case, a lamp). The conduction angle is directly proportional to the charge time of the capacitor, which can be adjusted using the potentiometer.

In heater control circuits, the configuration is similar, but with additional components such as inductors (chokes) to manage the current flow and reduce voltage spikes during switching. The choke helps to smooth out the current, preventing sudden changes that could damage the triac or the load. The resistor across the diac ensures that it remains responsive to changes in the potentiometer setting, allowing for a more consistent output regardless of the position of the control knob.

Overall, the integration of diacs in triac circuits enhances their performance, providing a reliable solution for applications that require variable power control, such as lighting and heating systems. The design considerations, including component selection and layout, are crucial for achieving optimal performance and ensuring the longevity of the circuit.The diacs, because of their symmetrical bidirectional switching characteristics, are widely used as triggering devices in triac phase control circuits em ployed for lamp dimmer, heat control, universal motor speed control etc. Although a triac may be fired into the conducting state by a simple resistive triggering circuit, but triggering devices

are typically placed in series with the gates of SCRs and triacs as they give reliable and fast triggering. Diac is the most popular triggering device for the triac. This is illustrated in the following applications. The circuit for a triac controlled by an R-C phase-shift network and a diac is given in figure. This circuit is an example of a simple lamp dimmer. The triac conduction angle is adjusted by adjusting the potentiometer R. The longer the triac conducts, the brighter the lamp will be. The diac acts like an open-circuit until the voltage across the capacitor exceeds its breakover or switching voltage (and the triac`s required gate trigger voltage).

A typical diac-triac circuit used for smooth control of ac power to a heater is shown in figure. The capacitor C1 in series with choke L across the triac slows-up the voltage rise across the device during off-state. The resistor R4 across the diac ensures smooth control at all positions of potentiometer R2. The triac conduction angle is adjusted by adjusting the potentiometer R2. The longer the triac conducts, the larger the output will be from the heater. Thus a smooth control of the heat output from the heater is obtained. 🔗 External reference