DUAL TESLA COIL

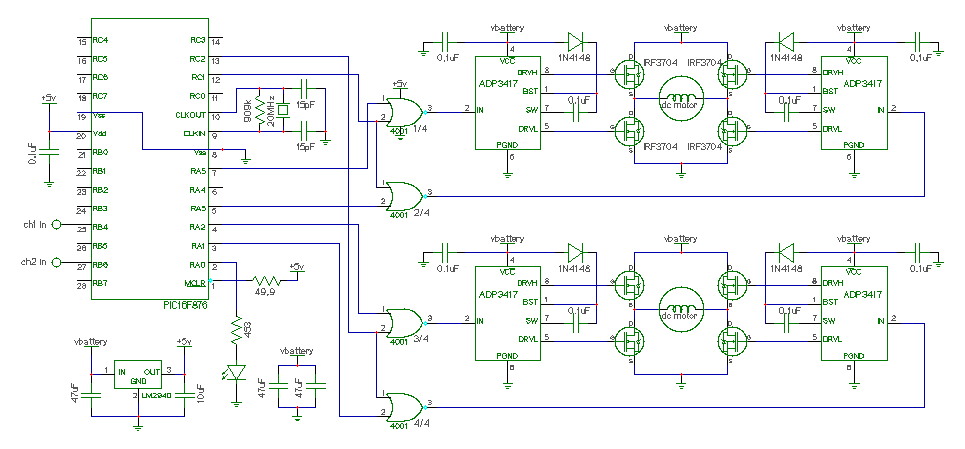

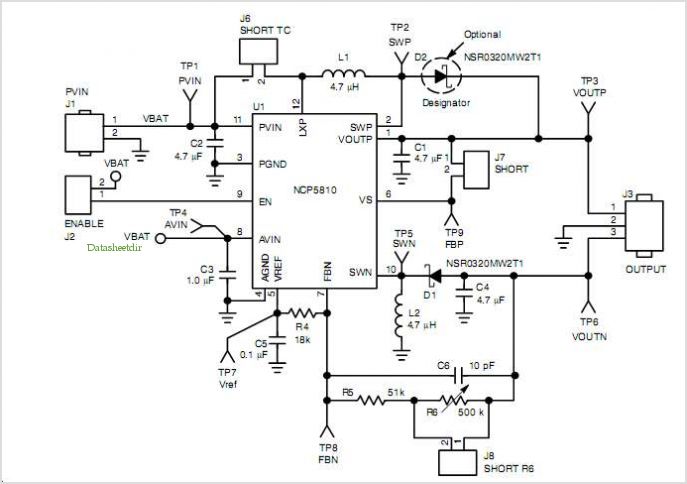

This area illustrates the construction and testing of a new half-wave (dual) Tesla coil. This type of coil features two secondaries driven by a single tank circuit. The design presented is a small and relatively inefficient dual coil constructed from scrap components for basic purposes. This section displays the functioning Tesla coil during testing, along with some minor improvements being implemented. The Tesla coil project primarily targets the scientific and Tesla coiling community, intended for lightning demonstrations and entertainment. Additionally, another variant of the Tesla coil design, known as a half-wave or "twin" Tesla coil, is described. This configuration consists of two primaries and secondaries, with the primaries wound 180 degrees out of phase in series. A single tank circuit capacitor and spark gap drive both opposing primaries, resulting in a split-phase output on each secondary top terminal, with the RF ground serving as a "center tap." The dual coil was constructed entirely from leftover scrap material from the main single Tesla coil project. Instead of discarding these materials, a small tabletop dual Tesla coil was created. The self-contained system is housed in a wood and plexiglass enclosure measuring approximately 6 inches high, 6 inches wide, and 16 inches long. High voltage power is supplied by a 10 kV, 23 mA oil burner transformer, which was unpotted from its tar case, placed in a separate compartment, and sealed in wax from melted old candles, becoming an integral part of the coil base unit. The tank circuit consists of two 30 kV, 0.0025 µF doorknob capacitors connected in parallel, resulting in a total capacitance of 0.005 µF. An MMC comprising 32 10 kV rated capacitors (0.008 µF total) sealed in wax was less effective, prompting the use of doorknob capacitors. The series spark gap is a linear static gap (RQ type) quenched with a 12 VDC fan, featuring four stainless steel electrodes measuring 3/4 inch by 3 inches, creating three gaps. The spark gap is series-connected through the opposing solenoid-type primary windings, which consist of approximately 10 turns of 1/4 inch copper tubing. Primary supports are fabricated from small plastic boxes and plastic wire ties, minimizing the risk of accidental contact with the primary coils. The secondary coils are formed with about 500 turns of close-wound #22 magnet wire on a 1 inch by 12 inch thin clear polycarbonate tube. PVC connectors are installed at each end of the secondaries, with the top terminal at one end and RF ground connections at the other. The shared RF ground is connected to a screw protruding from the top of the dual Tesla coil base. A screw terminal is also present at the top terminal of each secondary coil. Urethane varnish is applied to seal the secondaries. It is important to note that this dual Tesla coil was not designed for maximum spark length; rather, the objective was to construct a device from scrap materials that would otherwise have been discarded. This tabletop low-power unit generates a spark length of approximately three inches without any top loads on each secondary. It serves primarily for demonstration purposes of the Tesla coil concept in a less hazardous configuration. The system resonates in the MHz range, producing considerable RF energy during operation. The "wireless" light bulb trick operates effectively with this coil design despite the modest spark length. The accompanying diagram illustrates the schematic for the dual Tesla coil design. The dual coil is a half-lambda, or "twin" Tesla coil, constructed from spare parts leftover from the original Tesla coil trials. AC power at 120 volts enters through a main switch and a 750-watt dimmer switch. The dimmer output is directed to an oil burner ignition transformer, which generates 10,000 volts at 23 mA. The main switch supplies power to the dimmer and also powers the spark gap quench fan. The quench fan, a 12 VDC unit, has its own small DC power supply connected to the main switch prior to the dimmer. Parallel to the output of the oil burner ignition transformer is a 0.005 µF tank capacitor, composed of two 2500 pF doorknob capacitors.

The dual Tesla coil operates on the principles of resonance and electromagnetic induction, utilizing a unique configuration that allows for efficient energy transfer between the primary and secondary circuits. The primary circuit's inductance and the tank capacitor's capacitance work together to create oscillations at a specific resonant frequency, which is determined by the values of the components used. The spark gap acts as a switch, allowing current to flow through the primary winding when the voltage exceeds a certain threshold, thus generating a magnetic field. This magnetic field induces a high voltage in the secondary coil, resulting in the production of electrical discharges at the top terminal.

The design of the dual Tesla coil emphasizes safety and accessibility, as it is intended for educational demonstrations rather than high-power applications. The use of scrap materials not only reduces costs but also promotes sustainability within the electronics community. The compact size of the coil allows for easy transport and setup, making it suitable for various demonstration scenarios, including science fairs and educational workshops. The effective operation of the "wireless" light bulb trick further illustrates the principles of wireless power transmission, showcasing the coil's ability to transmit energy through the air without direct electrical connections. Overall, this dual Tesla coil serves as an excellent educational tool, providing insights into the fascinating world of high-voltage electricity and electromagnetic phenomena.This area shows the construction and testing of a new half-wave (dual) Tesla coil. This type of coil has two secondaries driven by a single tank circuit. The design shown here is a small and rather in-efficient dual coil constructed from scrap parts for basic purposes. This area shows the functioning Tesla coil being tested as well as some other m inor improvements being made. The tesla coil project is aimed mainly at the scientific and Tesla coiler community. I intend to use my Tesla coil for lightning demonstrations and entertainment. This section shows another different type of Tesla coil design called a half-wave or "twin" Tesla coil. Basically this type is two primaries and secondaries with the primaries wound 180 degrees out of phase in a series fashion.

A single tank circuit capacitor and spark gap drives both opposing primaries and a split phase output develops on each secondary top terminal with the RF ground acting as a "center tap". My dual coil was made entirely from scrap material that was left over after building the main single Tesla coil.

Instead of throwing it away, I decided to build a small table-top dual Tesla coil. The self-contained system is built in a wood and plexiglass box about 6 inches high, 6 inches wide, and about 16 inches long. The HV power is provided by the same small 10 kV, 23 mA oil burner transformer used in earlier experiments.

It was unpotted from its tar case, placed in its own compartment, and sealed in wax (from old candles melted down) becoming and integral part of the coil base unit. The tank circuit is two 30 kV, 0. 0025 uF doorknob type capacitors in parallel (0. 005 uF total). A MMC of 32 10 kV rated capacitors (0. 008 uF total) sealed in wax did not work too well so the doorknobs were used. The series spark gap is a linear static gap (RQ type) quenched with a 12 VDC fan. The spark gap has 4 stainless steel 3/4 inch by 3 inch electrodes giving 3 gaps. The spark gap is series connected through the opposing solenoid-type primary windings of about 10 turns of 1/4 inch copper tubing.

The primary supports are made with small plastic boxes and plastic wire-ties and also reduce the risk accidental contacts with the primary coils. The secondary forms are about 500 turns of close-wound #22 magnet wire on a 1 inch by 12 inch thin clear polycarbonate tube.

PVC connectors are at each end of the secondaries, with the top terminal at one end and RF ground connections at the other. The shared RF ground is connected to a screw that sticks out of the top of the dual Tesla coil base. A screw terminal is also at the top terminal of each secondary coil. Urethane varnish was used to seal the secondaries. Notes - This dual Tesla coil was NOT designed for maximum spark length. The approach was to build such a device from scrap meterials that otherwise would have been thrown away!

This table-top low power unit only produces a spark length of about three inches without any top loads on each secondary. It is mainly used for demonstration of the Tesla coil concept in a less-dangerous package. The system also resonates in the mHZ range, and considerable RF energy is produced by the unit when operating.

The "wireless" light bulb trick works very well with this coil design despite the small sparks. The diagram above is the schematic for my dual Tesla coil design. The dual coil is a half-lambda, or "twin" Tesla coil constructed from spare parts left over from the original Tesla coil trials. AC power is 120 Volts and enters via a main switch and 750 Watt dimmer switch. The dimmer output is fed to an oil burner ignition transformer which produces 10, 000 volts at 23 mA.

The main switch supplys the dimmer and also powers the spark gap quench fan. The quench fan is a 12 VDC fan with its own small DC power supply connected to the main switch before the dimmer. Parallel-connected to the output of the OBIT is a 0. 005 uF tank capacitor (two 2500 pf doorkno 🔗 External reference

The dual Tesla coil operates on the principles of resonance and electromagnetic induction, utilizing a unique configuration that allows for efficient energy transfer between the primary and secondary circuits. The primary circuit's inductance and the tank capacitor's capacitance work together to create oscillations at a specific resonant frequency, which is determined by the values of the components used. The spark gap acts as a switch, allowing current to flow through the primary winding when the voltage exceeds a certain threshold, thus generating a magnetic field. This magnetic field induces a high voltage in the secondary coil, resulting in the production of electrical discharges at the top terminal.

The design of the dual Tesla coil emphasizes safety and accessibility, as it is intended for educational demonstrations rather than high-power applications. The use of scrap materials not only reduces costs but also promotes sustainability within the electronics community. The compact size of the coil allows for easy transport and setup, making it suitable for various demonstration scenarios, including science fairs and educational workshops. The effective operation of the "wireless" light bulb trick further illustrates the principles of wireless power transmission, showcasing the coil's ability to transmit energy through the air without direct electrical connections. Overall, this dual Tesla coil serves as an excellent educational tool, providing insights into the fascinating world of high-voltage electricity and electromagnetic phenomena.This area shows the construction and testing of a new half-wave (dual) Tesla coil. This type of coil has two secondaries driven by a single tank circuit. The design shown here is a small and rather in-efficient dual coil constructed from scrap parts for basic purposes. This area shows the functioning Tesla coil being tested as well as some other m inor improvements being made. The tesla coil project is aimed mainly at the scientific and Tesla coiler community. I intend to use my Tesla coil for lightning demonstrations and entertainment. This section shows another different type of Tesla coil design called a half-wave or "twin" Tesla coil. Basically this type is two primaries and secondaries with the primaries wound 180 degrees out of phase in a series fashion.

A single tank circuit capacitor and spark gap drives both opposing primaries and a split phase output develops on each secondary top terminal with the RF ground acting as a "center tap". My dual coil was made entirely from scrap material that was left over after building the main single Tesla coil.

Instead of throwing it away, I decided to build a small table-top dual Tesla coil. The self-contained system is built in a wood and plexiglass box about 6 inches high, 6 inches wide, and about 16 inches long. The HV power is provided by the same small 10 kV, 23 mA oil burner transformer used in earlier experiments.

It was unpotted from its tar case, placed in its own compartment, and sealed in wax (from old candles melted down) becoming and integral part of the coil base unit. The tank circuit is two 30 kV, 0. 0025 uF doorknob type capacitors in parallel (0. 005 uF total). A MMC of 32 10 kV rated capacitors (0. 008 uF total) sealed in wax did not work too well so the doorknobs were used. The series spark gap is a linear static gap (RQ type) quenched with a 12 VDC fan. The spark gap has 4 stainless steel 3/4 inch by 3 inch electrodes giving 3 gaps. The spark gap is series connected through the opposing solenoid-type primary windings of about 10 turns of 1/4 inch copper tubing.

The primary supports are made with small plastic boxes and plastic wire-ties and also reduce the risk accidental contacts with the primary coils. The secondary forms are about 500 turns of close-wound #22 magnet wire on a 1 inch by 12 inch thin clear polycarbonate tube.

PVC connectors are at each end of the secondaries, with the top terminal at one end and RF ground connections at the other. The shared RF ground is connected to a screw that sticks out of the top of the dual Tesla coil base. A screw terminal is also at the top terminal of each secondary coil. Urethane varnish was used to seal the secondaries. Notes - This dual Tesla coil was NOT designed for maximum spark length. The approach was to build such a device from scrap meterials that otherwise would have been thrown away!

This table-top low power unit only produces a spark length of about three inches without any top loads on each secondary. It is mainly used for demonstration of the Tesla coil concept in a less-dangerous package. The system also resonates in the mHZ range, and considerable RF energy is produced by the unit when operating.

The "wireless" light bulb trick works very well with this coil design despite the small sparks. The diagram above is the schematic for my dual Tesla coil design. The dual coil is a half-lambda, or "twin" Tesla coil constructed from spare parts left over from the original Tesla coil trials. AC power is 120 Volts and enters via a main switch and 750 Watt dimmer switch. The dimmer output is fed to an oil burner ignition transformer which produces 10, 000 volts at 23 mA.

The main switch supplys the dimmer and also powers the spark gap quench fan. The quench fan is a 12 VDC fan with its own small DC power supply connected to the main switch before the dimmer. Parallel-connected to the output of the OBIT is a 0. 005 uF tank capacitor (two 2500 pf doorkno 🔗 External reference