Electric Oven automatic temperature controller

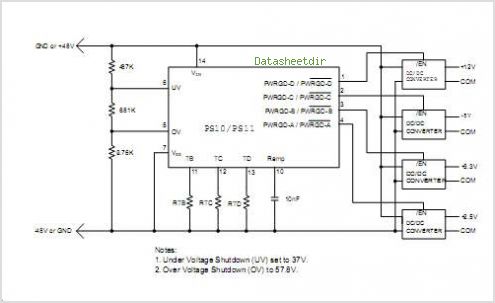

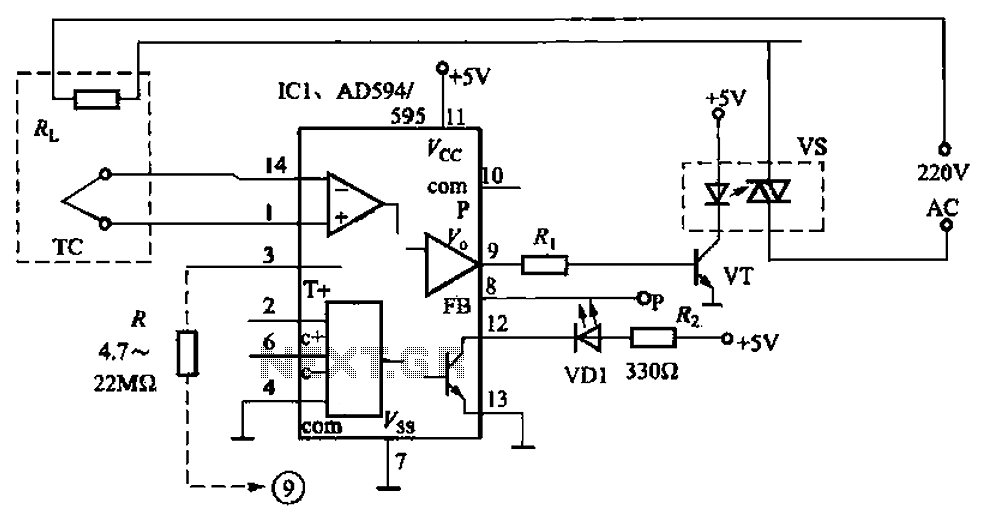

An automatic electric furnace temperature controller is depicted in FIG. 1-25. The closed circuit is established through a temperature detection output control loop. As the temperature rises, the output voltage increases. When the voltage reaches a preset temperature value, the output stops, halting the heating process. Conversely, when the temperature decreases to a predetermined level, the system automatically resumes heating. A thermocouple (TC) is directly connected to the input of IC1, which sends the signal to an internal differential amplifier. The output from this amplifier drives a solid-state relay (VT), which, in turn, controls the ohmic heating element (RL). When the heating element reaches the preset temperature, the output is ceased. The input and output hysteresis settings are configured via a resistor (R) connected to a specific pin; a lower resistance value results in greater hysteresis. The temperature control is influenced by the voltage at the decision-making pins, as outlined in Table 1-3. The AD594/595 also includes a zero offset circuit, though it is not utilized in this application. Alarm pins indicate the output status, and an open transistor can directly drive an LED or small relays. The LED (VD1) serves as a working indicator to show the heating status.

The automatic electric furnace temperature controller operates as a feedback system, utilizing a thermocouple (TC) for precise temperature measurement. The TC generates a voltage output proportional to the temperature, which is fed into an integrated circuit (IC1) that contains a differential amplifier. The differential amplifier compares the TC output voltage against a reference voltage set by an external resistor divider network. As the temperature rises, the output voltage from the differential amplifier increases until it reaches a threshold level defined by the set point. At this juncture, the output to the solid-state relay (VT) is interrupted, effectively stopping the heating process.

The solid-state relay is employed for its rapid switching capabilities and durability compared to mechanical relays. It connects to the heating element (RL), which is typically a resistive load. As the temperature drops below the set point, the TC's voltage output decreases, prompting the differential amplifier to reactivate the solid-state relay, thus restarting the heating cycle.

The hysteresis feature, adjustable via the resistor (R), prevents rapid cycling of the heating element by introducing a temperature band within which the system will not react to minor fluctuations. This is crucial for maintaining a stable temperature and prolonging the lifespan of the heating element and relay.

The controller also integrates alarm functionality through designated pins, which can signal the status of the system. The open transistor configuration allows for direct interfacing with visual or auditory indicators, such as LEDs or buzzers, enhancing user awareness of the system's operational state. The inclusion of a zero offset circuit in the AD594/595 may provide additional calibration capabilities, ensuring accurate temperature readings under varying conditions, although it is not utilized in this specific design.

Overall, the automatic electric furnace temperature controller exemplifies an efficient and reliable method for managing heating processes, suitable for various industrial and laboratory applications. Automatic electric furnace temperature controller shown in FIG. 1-25. The closed circuit is formed from a temperature detection output control loop; the temperature rises, the output voltage increases when the voltage increases to a preset temperature value, the output stop, stop heating; trans, the temperature is lowered, when reduced to the pre when the set temperature, and automatically starts heating. TC thermocouple directly connected to IC1 s O, ? feet, sending internal differential amplifier, the output from a foot, driven by solid state relay vs VT conduction, plus hot wires RL ohmic heating, when heated to a preset temperature, output is stopped.

pin input and output hysteresis setting, connected to a pin through resistor R to achieve, the smaller the resistance value, the greater the hysteresis. Controlling the temperature of the high and low foot by pressing decisions relations pin voltage and temperature, TC between as shown in Table 1-3.

AD594/595 is also designed with zero offset circuit (not used here). ?, ? pin alarm, indicating the output of the internal as c, e very open transistor can directly drive LED or small relays, access here VD1 as the working lights for indicating the start and stop on heating.

The automatic electric furnace temperature controller operates as a feedback system, utilizing a thermocouple (TC) for precise temperature measurement. The TC generates a voltage output proportional to the temperature, which is fed into an integrated circuit (IC1) that contains a differential amplifier. The differential amplifier compares the TC output voltage against a reference voltage set by an external resistor divider network. As the temperature rises, the output voltage from the differential amplifier increases until it reaches a threshold level defined by the set point. At this juncture, the output to the solid-state relay (VT) is interrupted, effectively stopping the heating process.

The solid-state relay is employed for its rapid switching capabilities and durability compared to mechanical relays. It connects to the heating element (RL), which is typically a resistive load. As the temperature drops below the set point, the TC's voltage output decreases, prompting the differential amplifier to reactivate the solid-state relay, thus restarting the heating cycle.

The hysteresis feature, adjustable via the resistor (R), prevents rapid cycling of the heating element by introducing a temperature band within which the system will not react to minor fluctuations. This is crucial for maintaining a stable temperature and prolonging the lifespan of the heating element and relay.

The controller also integrates alarm functionality through designated pins, which can signal the status of the system. The open transistor configuration allows for direct interfacing with visual or auditory indicators, such as LEDs or buzzers, enhancing user awareness of the system's operational state. The inclusion of a zero offset circuit in the AD594/595 may provide additional calibration capabilities, ensuring accurate temperature readings under varying conditions, although it is not utilized in this specific design.

Overall, the automatic electric furnace temperature controller exemplifies an efficient and reliable method for managing heating processes, suitable for various industrial and laboratory applications. Automatic electric furnace temperature controller shown in FIG. 1-25. The closed circuit is formed from a temperature detection output control loop; the temperature rises, the output voltage increases when the voltage increases to a preset temperature value, the output stop, stop heating; trans, the temperature is lowered, when reduced to the pre when the set temperature, and automatically starts heating. TC thermocouple directly connected to IC1 s O, ? feet, sending internal differential amplifier, the output from a foot, driven by solid state relay vs VT conduction, plus hot wires RL ohmic heating, when heated to a preset temperature, output is stopped.

pin input and output hysteresis setting, connected to a pin through resistor R to achieve, the smaller the resistance value, the greater the hysteresis. Controlling the temperature of the high and low foot by pressing decisions relations pin voltage and temperature, TC between as shown in Table 1-3.

AD594/595 is also designed with zero offset circuit (not used here). ?, ? pin alarm, indicating the output of the internal as c, e very open transistor can directly drive LED or small relays, access here VD1 as the working lights for indicating the start and stop on heating.