electronic design software for large electronics

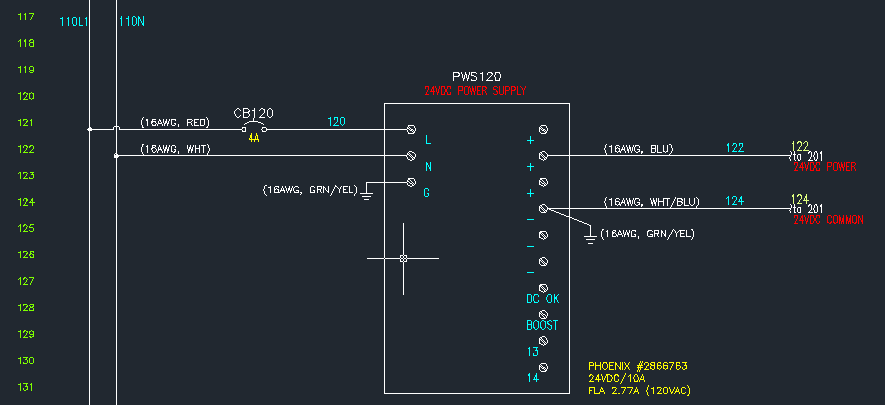

The power supply unit (PSU) in question does not appear to be exceptionally large. Eagle software should be capable of managing these dimensions. The focus was more on finding an alternative that may already include the necessary components and be better suited for this design, possibly allowing for color-coded wiring. However, it is acknowledged that with Eagle labels, text can be input for identification. Additionally, it is noted that there are specific conventions for drawing these units, and the optimal method may be found in various software programs. For instance, an outlet with a switch is depicted in the Schaffaur FN284 link. No schematic or layout software will have every component footprint readily available. A significant aspect of working in electronics involves either building, purchasing, or subscribing to a footprint library containing all commonly encountered parts. Eagle offers a substantial number of footprints, and many more are accessible for free on their website, although it remains incomplete. Typically, a dozen or more parts are added to personal libraries each year.

In the context of electronic design automation (EDA), the choice of software tools is critical for efficient workflow and effective circuit design. The Eagle software, known for its user-friendly interface and extensive component library, is particularly suitable for designing power supply units. The dimensions of the PSU under consideration suggest that Eagle can accommodate the required layout without issues.

When designing a PSU, it is essential to adhere to established conventions for schematic representation. This includes the correct depiction of components such as outlets, switches, and connectors, which can significantly impact the clarity and functionality of the design. The reference to the Schaffaur FN284 illustrates the importance of utilizing existing examples to guide the design process.

Moreover, the availability of component footprints is a crucial factor in the design process. While Eagle provides a wide range of footprints, it is acknowledged that no single software package can encompass every possible component. Therefore, engineers often need to develop their own libraries or enhance existing ones with additional parts they frequently encounter. This can include custom footprints for specific components or modifications of existing footprints to better fit the design requirements.

In conclusion, the effective use of Eagle software for PSU design relies on a combination of proper schematic conventions, the utilization of available resources, and the continuous expansion of personal component libraries. By maintaining an up-to-date library and leveraging the software's capabilities, designers can streamline their workflow and enhance the overall quality of their electronic designs.The PSU you`re referring to doesn`t look extraordinarily large to me.Eagle should be able to handle this kind of dimensions. I was more looking for something that may already have the components and be more suited for this kind of design (perhaps allow you to give wires colors, though I suppose with the Eagle labels we can type it out).

Also @stevenvh thank you for the edit. It isnt a size thing, it`s more that there are certain ways to draw these units, and the best way may be available in these programs. For example an outlet with a swtich that is present in the Schaffaur FN284 link. No schematic/layout package will have every component footprint you`ll ever need waiting for you. Part of doing electronics work is building up (or buying, or subscribing to) a footprint library consisting of all the parts you usually run across. Eagle has a lot of footprints, and there are plenty more freely available on their site, but it`s not complete by any means.

I usually end up adding a dozen or so parts to my library each year. 🔗 External reference

In the context of electronic design automation (EDA), the choice of software tools is critical for efficient workflow and effective circuit design. The Eagle software, known for its user-friendly interface and extensive component library, is particularly suitable for designing power supply units. The dimensions of the PSU under consideration suggest that Eagle can accommodate the required layout without issues.

When designing a PSU, it is essential to adhere to established conventions for schematic representation. This includes the correct depiction of components such as outlets, switches, and connectors, which can significantly impact the clarity and functionality of the design. The reference to the Schaffaur FN284 illustrates the importance of utilizing existing examples to guide the design process.

Moreover, the availability of component footprints is a crucial factor in the design process. While Eagle provides a wide range of footprints, it is acknowledged that no single software package can encompass every possible component. Therefore, engineers often need to develop their own libraries or enhance existing ones with additional parts they frequently encounter. This can include custom footprints for specific components or modifications of existing footprints to better fit the design requirements.

In conclusion, the effective use of Eagle software for PSU design relies on a combination of proper schematic conventions, the utilization of available resources, and the continuous expansion of personal component libraries. By maintaining an up-to-date library and leveraging the software's capabilities, designers can streamline their workflow and enhance the overall quality of their electronic designs.The PSU you`re referring to doesn`t look extraordinarily large to me.Eagle should be able to handle this kind of dimensions. I was more looking for something that may already have the components and be more suited for this kind of design (perhaps allow you to give wires colors, though I suppose with the Eagle labels we can type it out).

Also @stevenvh thank you for the edit. It isnt a size thing, it`s more that there are certain ways to draw these units, and the best way may be available in these programs. For example an outlet with a swtich that is present in the Schaffaur FN284 link. No schematic/layout package will have every component footprint you`ll ever need waiting for you. Part of doing electronics work is building up (or buying, or subscribing to) a footprint library consisting of all the parts you usually run across. Eagle has a lot of footprints, and there are plenty more freely available on their site, but it`s not complete by any means.

I usually end up adding a dozen or so parts to my library each year. 🔗 External reference