Features and Power Control Circuit

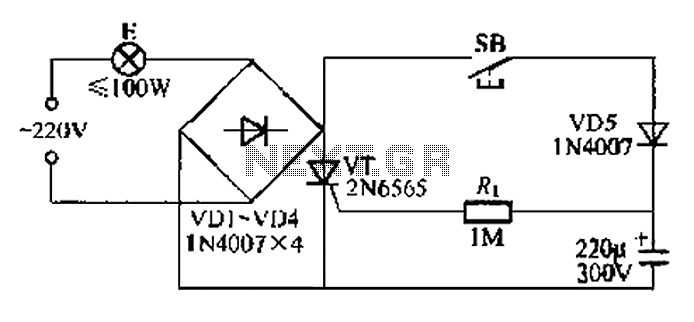

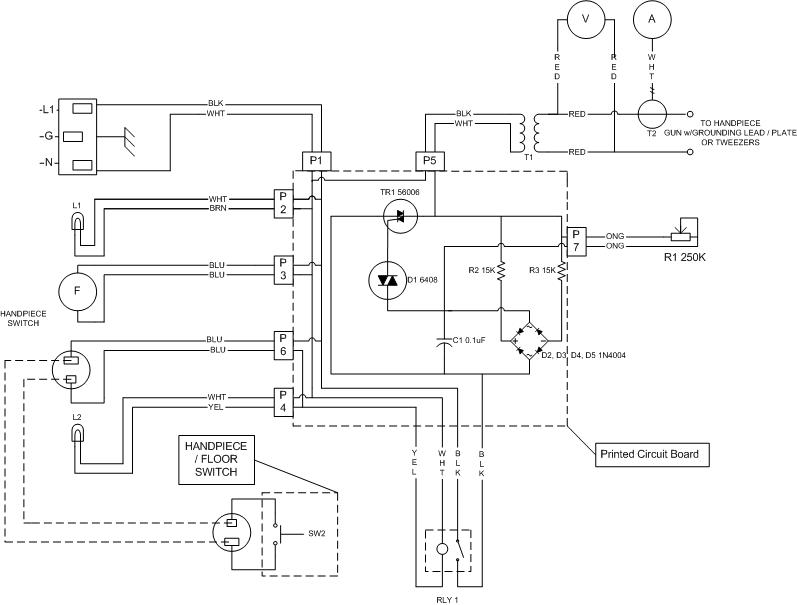

The most challenging aspect of the build was to find or design a circuit capable of handling the load while remaining within budget. This circuit achieves both objectives. It adjusts the power output using a potentiometer (variable resistor) R1, which is a panel-mount potentiometer with a shaft for a knob. The power adjustment is accomplished through synchronous triggering across the triac. In the triac TR1, terminal T1 serves as the input, terminal T2 as the output, and G as the gate. All components were readily available from a local electronics supply store and assembled on a point-to-point prototype circuit board. This simple yet reliable circuit can handle up to 15 Amps, but in this application, it operates at approximately 4 Amps since it controls the primary windings of the transformer. This circuit can also be adapted for various applications requiring power control, such as a lamp dimmer or providing variable speed for AC motors like drills. When switch SW1 is activated, L1 and FAN1 are powered on. The switching and control are performed on the primary side of T1, where the voltage is higher (120VAC) but the current is lower. The circuit switches incoming AC into the power control circuit through relay RLY1, which is controlled by switch SW2. The current draw of RLY1 is minimal, allowing SW2 to be compact and mountable in various locations, such as in a pistol-like soldering gun. SW2 is positioned in the trigger location, eliminating the need for a foot switch. A floor switch is still used with the tweezer setup. Relay RLY1 activates L2, which is mounted on the front panel. Voltage is supplied from the power control circuit to T1. The maximum current draw for the power control circuit, including RLY1, FAN1, and T1 at full power, is approximately 4 Amps. Therefore, RLY1 should be rated for at least 10A, while fuse F1 is rated at 4.5A. A voltmeter and an ammeter are installed at the output of T1, providing insight into the wattage output for soldering operations. For example, if 2 volts and 20 amps are measured, using Ohm's law, METER2 (voltmeter) is connected across T1, and METER1 (ammeter) is connected to T2 (current transformer). T2 is made from four 2-inch steel washers welded together to form a thick doughnut core. Light gauge wire is wrapped through the hole and around the outside, with about 60 turns connected to the meter terminals. The output of T1 is also wrapped about six times through the hole, matching the transformer to METER1, which closely aligns with actual output as verified by a Fluke meter. When the power is set to maximum, approximately 50 amps at 4 volts can be drawn, equating to 200 watts. Interestingly, the primary side of T1 draws about 4 amps at maximum, resulting in 480 watts (120 volts x 4 amps). The discrepancy between the input and output indicates power loss, primarily due to heat dissipation, necessitating effective cooling, with a cooling fan and a duty cycle rated at 25%. For every minute of operation, the unit is allowed to rest for four minutes, although typical cycles last only a few seconds. A substantial heat sink is also installed on TR1. Additionally, T1 features a center tap; using this tap reduces the output to about 6 VAC. A planned test will assess performance at lower voltage levels. The schematic and accompanying picture illustrate the use of the circuit board as a central connection point, with color-coded wiring for clarity. All external devices connect to the board, facilitating easy removal and servicing of both the board and outboard components, allowing for straightforward modifications.

The circuit design incorporates a triac (TR1), which serves as the primary switching element, providing efficient control of AC power. The use of a potentiometer (R1) allows for fine-tuning of the output, enabling the user to adjust power levels according to specific requirements. The relay (RLY1) plays a crucial role in controlling the power flow to the load, ensuring that the system operates safely and reliably. The integration of meters for voltage and current measurement enhances the functionality of the circuit, allowing for real-time monitoring of performance and facilitating troubleshooting.

The cooling strategy, including the use of a fan and heat sink, is essential for maintaining optimal operating conditions, particularly given the potential for heat generation during high-power operation. The design's emphasis on modularity and accessibility through the circuit board layout promotes ease of maintenance and adaptability for future enhancements or modifications.

Overall, this circuit exemplifies a practical solution for power control applications, combining simplicity, reliability, and versatility, making it suitable for a range of electronic projects and devices.The hardest part of the build was to find and / or design a circuit that could handle the load and still stay with in my budget. This little circuit does both. It varies the power output with one potentiometer (variable resistor) R1. R1 is a panel-mount pot with a shaft for a knob. It varies the power by synchronous triggering across the triac. On the triac TR1, terminal T1 is input, terminal T2 is output and G is the gate. All the parts were readily available form my local electronic supply store and built on a point to point prototype circuit board. This is a simple but a reliable circuit which will handle 15 Amps but in my unit it only has to about 4 Amps since I am controlling the primary windings of the transformer.

On a side note, this circuit can be adapted to numerous other applications where controlling power is a requirement as in a lamp dimmer or putting a variable speed feature on an AC motor like a drill. As soon as SW1 is turned on, L1 and FAN1 come on. I wanted to do all the switching and control on the primary side of T1. Even though the voltage is higher (120VAC), the current would be much lower. The circuit is switching the incoming AC into the power control circuit thru relay RLY1. In turn, RLY1 is being controlled by SW2. The current draw of RLY1 is very small so this allows SW2 to be compact allowing mounting almost anywhere as in my pistol like soldering gun (carbon rod holder).

I mounted SW2 in the trigger position eliminating the need for a foot switch. With my tweezer set up, the floor switch is still employed. L2 comes on with RLY1 and is mounted to the front panel. Voltage is fed from the power control circuit to T1. The highest current draw that the power control circuit with RLY1, FAN1 and T1 at full power is approximately 4 Amps. Since all this is passing thru RLY1, RLY1 should be rated for at least 10A. I rated F1 at 4. 5A. On the output of T1, a voltage meter and an amp meter are installed. This gives me a good idea of the wattage output for any soldering operation. For instance, if I read 2 volts and 20 amps, using Ohm`s law: METER2 (volt meter) is connected across T1 while METER1 (amp meter) is connected to T2 (current transformer).

T2 was constructed from four 2 steel washers welded together to make one thick doughnut core. Light gauge wire was wrapped thru the hole and around the outside. I wrapped about 60 turns of the wire and connected each end to the meter terminals. The output of T1 was also wrapped about 6 times thru the hole. This matched the transformer to METER1 which brought it very close to the actual output as tested by my Fluke meter. With power set to MAX, I can pull about 50 amps @ 4 volts which is exactly 200 watts! Interestingly enough the primary side of T1, draws about 4 amps on MAX. So again using Ohm`s law, this comes to 480 watts (120volts x 4amps). With 480 watts going in and only 200 watts coming out the rest must be loss. A lot of this loss is dissipated by heat so that`s why I found it important to keep the unit as cool as possible with the cooling fan and rate it at 25% duty cycle.

For every minute of operation I let it rest for four all though a typical cycle only lasts a few seconds. I also have a good size heat sink on TR1. Also of note, T1 has a center tap. If the center tap is used, the output drops to about 6 VAC. One item I am meaning to test is the operation on the lower voltage to find out if there is a performance gain.

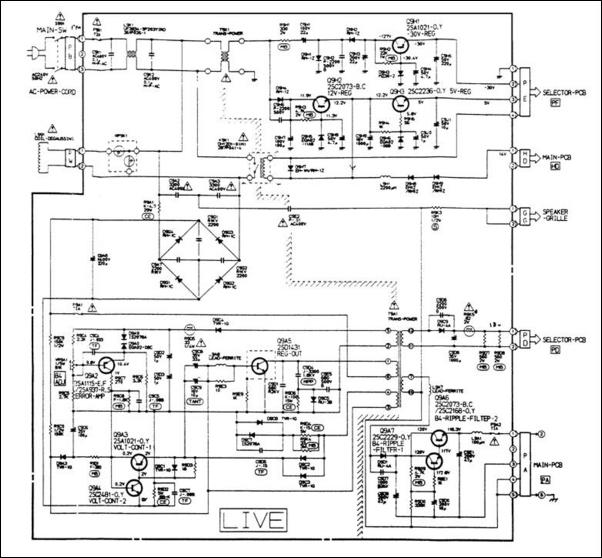

This picture and schematic 3 show how I used the circuit board as a central connection point and colour coded the wiring. All external devices plug into the board. This will allow easy removal and service of the board and the outboard components. This feature also permits easy modifications! And this is all the components put together. I made a false bottom plate so every time I wanted to change the internal configuration, it was just a matter of replacing it rat

🔗 External reference

The circuit design incorporates a triac (TR1), which serves as the primary switching element, providing efficient control of AC power. The use of a potentiometer (R1) allows for fine-tuning of the output, enabling the user to adjust power levels according to specific requirements. The relay (RLY1) plays a crucial role in controlling the power flow to the load, ensuring that the system operates safely and reliably. The integration of meters for voltage and current measurement enhances the functionality of the circuit, allowing for real-time monitoring of performance and facilitating troubleshooting.

The cooling strategy, including the use of a fan and heat sink, is essential for maintaining optimal operating conditions, particularly given the potential for heat generation during high-power operation. The design's emphasis on modularity and accessibility through the circuit board layout promotes ease of maintenance and adaptability for future enhancements or modifications.

Overall, this circuit exemplifies a practical solution for power control applications, combining simplicity, reliability, and versatility, making it suitable for a range of electronic projects and devices.The hardest part of the build was to find and / or design a circuit that could handle the load and still stay with in my budget. This little circuit does both. It varies the power output with one potentiometer (variable resistor) R1. R1 is a panel-mount pot with a shaft for a knob. It varies the power by synchronous triggering across the triac. On the triac TR1, terminal T1 is input, terminal T2 is output and G is the gate. All the parts were readily available form my local electronic supply store and built on a point to point prototype circuit board. This is a simple but a reliable circuit which will handle 15 Amps but in my unit it only has to about 4 Amps since I am controlling the primary windings of the transformer.

On a side note, this circuit can be adapted to numerous other applications where controlling power is a requirement as in a lamp dimmer or putting a variable speed feature on an AC motor like a drill. As soon as SW1 is turned on, L1 and FAN1 come on. I wanted to do all the switching and control on the primary side of T1. Even though the voltage is higher (120VAC), the current would be much lower. The circuit is switching the incoming AC into the power control circuit thru relay RLY1. In turn, RLY1 is being controlled by SW2. The current draw of RLY1 is very small so this allows SW2 to be compact allowing mounting almost anywhere as in my pistol like soldering gun (carbon rod holder).

I mounted SW2 in the trigger position eliminating the need for a foot switch. With my tweezer set up, the floor switch is still employed. L2 comes on with RLY1 and is mounted to the front panel. Voltage is fed from the power control circuit to T1. The highest current draw that the power control circuit with RLY1, FAN1 and T1 at full power is approximately 4 Amps. Since all this is passing thru RLY1, RLY1 should be rated for at least 10A. I rated F1 at 4. 5A. On the output of T1, a voltage meter and an amp meter are installed. This gives me a good idea of the wattage output for any soldering operation. For instance, if I read 2 volts and 20 amps, using Ohm`s law: METER2 (volt meter) is connected across T1 while METER1 (amp meter) is connected to T2 (current transformer).

T2 was constructed from four 2 steel washers welded together to make one thick doughnut core. Light gauge wire was wrapped thru the hole and around the outside. I wrapped about 60 turns of the wire and connected each end to the meter terminals. The output of T1 was also wrapped about 6 times thru the hole. This matched the transformer to METER1 which brought it very close to the actual output as tested by my Fluke meter. With power set to MAX, I can pull about 50 amps @ 4 volts which is exactly 200 watts! Interestingly enough the primary side of T1, draws about 4 amps on MAX. So again using Ohm`s law, this comes to 480 watts (120volts x 4amps). With 480 watts going in and only 200 watts coming out the rest must be loss. A lot of this loss is dissipated by heat so that`s why I found it important to keep the unit as cool as possible with the cooling fan and rate it at 25% duty cycle.

For every minute of operation I let it rest for four all though a typical cycle only lasts a few seconds. I also have a good size heat sink on TR1. Also of note, T1 has a center tap. If the center tap is used, the output drops to about 6 VAC. One item I am meaning to test is the operation on the lower voltage to find out if there is a performance gain.

This picture and schematic 3 show how I used the circuit board as a central connection point and colour coded the wiring. All external devices plug into the board. This will allow easy removal and service of the board and the outboard components. This feature also permits easy modifications! And this is all the components put together. I made a false bottom plate so every time I wanted to change the internal configuration, it was just a matter of replacing it rat

🔗 External reference