FLOW METER

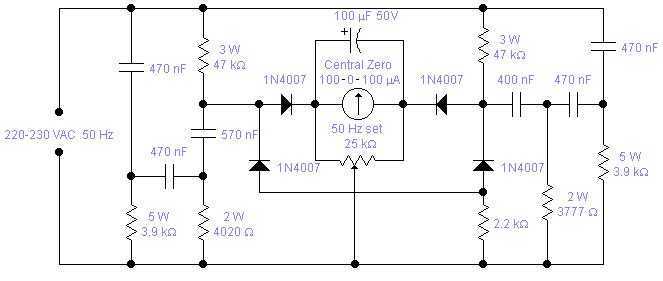

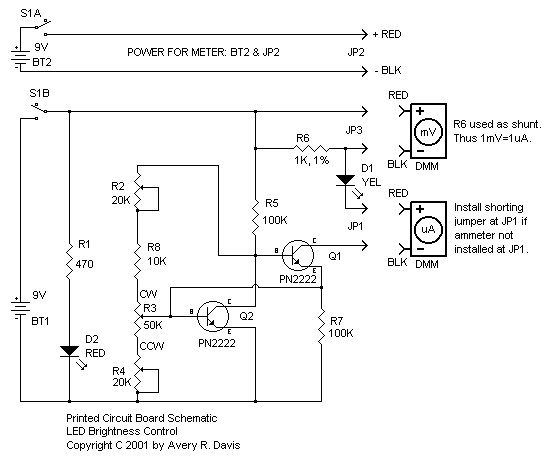

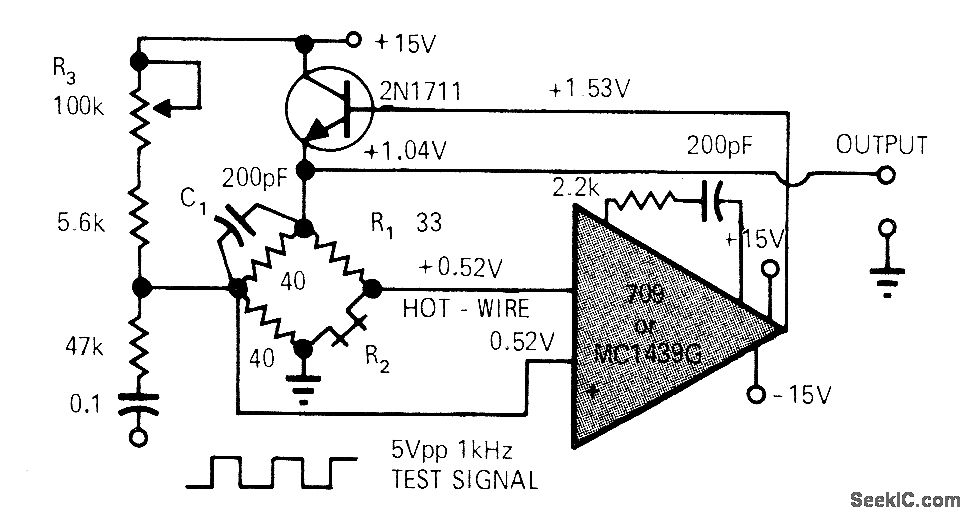

A simple operational amplifier (op-amp) circuit combined with a transistor creates a reliable hot-wire anemometer for measuring the flow of gases or liquids. Resistor R2 is heated above ambient temperature within a Wheatstone bridge configuration that includes an overheat resistor, R1, which is calibrated to be 30% larger than the cold resistance of R2. The bridge is powered by a transistor that is part of the feedback loop of the op-amp, which senses the bridge's unbalance. The output of the bridge is fed back to the power transistor in the correct phase to maintain a constant temperature condition, ensuring that R2 is approximately equal to R1. The article discusses the construction of a hot-wire probe made from Wollaston wire.

The described circuit utilizes a Wheatstone bridge to measure resistance changes in the hot-wire anemometer. The bridge consists of four resistors, where R2 is the sensing element that responds to changes in fluid flow by changing its temperature and resistance. The overheat resistor R1 is strategically chosen to ensure that the circuit operates effectively within the desired temperature range. The op-amp amplifies the difference in voltage across the bridge, which indicates any imbalance caused by changes in the resistance of R2 due to varying flow conditions.

The feedback loop is crucial for maintaining the temperature of R2 at a constant level, which is essential for accurate flow measurements. The op-amp continuously adjusts the power supplied to the transistor based on the output of the Wheatstone bridge, ensuring that R2 remains at a temperature that is consistently higher than the surrounding environment. This feedback mechanism allows for precise control of the heating element, which is vital for the anemometer's functionality.

The construction of the hot-wire probe itself is also significant. Using Wollaston wire, known for its fine diameter and high resistance, enhances the sensitivity of the measurement. The wire's small mass allows for rapid thermal response, making it ideal for detecting minute changes in flow velocity. Proper insulation and mounting of the wire are critical to prevent heat loss and ensure accurate readings.

Overall, this op-amp and transistor circuit design provides a robust solution for fluid flow measurement, leveraging the principles of thermodynamics and electrical feedback to achieve high precision in various applications.Simple opamp circuit with one transistor gives reliable hot-wire anemometer for measuring flow of gases or liquids. R2 is heated above ambient temperature in Wheatstone bridge including overheat resistor R1which is calibrated to be 30% larger than cold resistance of R2.

Bridge is fed from power tran. sistor which is within feedback loop of opamp th at senses bridge unbalance. Output of bridge is fed back to power transistor in correct phase for maintaining constant- temperature condition in which R2 is approximately equal to R1. Article covers construction of hot-wire probe made from Wollaston wire. -W. Bank, Build Your Own Constant-Temperature Hot-Wire Anemometer, EDN Magazine, Aug. 1, 1972, p 43. 🔗 External reference

The described circuit utilizes a Wheatstone bridge to measure resistance changes in the hot-wire anemometer. The bridge consists of four resistors, where R2 is the sensing element that responds to changes in fluid flow by changing its temperature and resistance. The overheat resistor R1 is strategically chosen to ensure that the circuit operates effectively within the desired temperature range. The op-amp amplifies the difference in voltage across the bridge, which indicates any imbalance caused by changes in the resistance of R2 due to varying flow conditions.

The feedback loop is crucial for maintaining the temperature of R2 at a constant level, which is essential for accurate flow measurements. The op-amp continuously adjusts the power supplied to the transistor based on the output of the Wheatstone bridge, ensuring that R2 remains at a temperature that is consistently higher than the surrounding environment. This feedback mechanism allows for precise control of the heating element, which is vital for the anemometer's functionality.

The construction of the hot-wire probe itself is also significant. Using Wollaston wire, known for its fine diameter and high resistance, enhances the sensitivity of the measurement. The wire's small mass allows for rapid thermal response, making it ideal for detecting minute changes in flow velocity. Proper insulation and mounting of the wire are critical to prevent heat loss and ensure accurate readings.

Overall, this op-amp and transistor circuit design provides a robust solution for fluid flow measurement, leveraging the principles of thermodynamics and electrical feedback to achieve high precision in various applications.Simple opamp circuit with one transistor gives reliable hot-wire anemometer for measuring flow of gases or liquids. R2 is heated above ambient temperature in Wheatstone bridge including overheat resistor R1which is calibrated to be 30% larger than cold resistance of R2.

Bridge is fed from power tran. sistor which is within feedback loop of opamp th at senses bridge unbalance. Output of bridge is fed back to power transistor in correct phase for maintaining constant- temperature condition in which R2 is approximately equal to R1. Article covers construction of hot-wire probe made from Wollaston wire. -W. Bank, Build Your Own Constant-Temperature Hot-Wire Anemometer, EDN Magazine, Aug. 1, 1972, p 43. 🔗 External reference