Freescale unveils highly integrated TPMS device

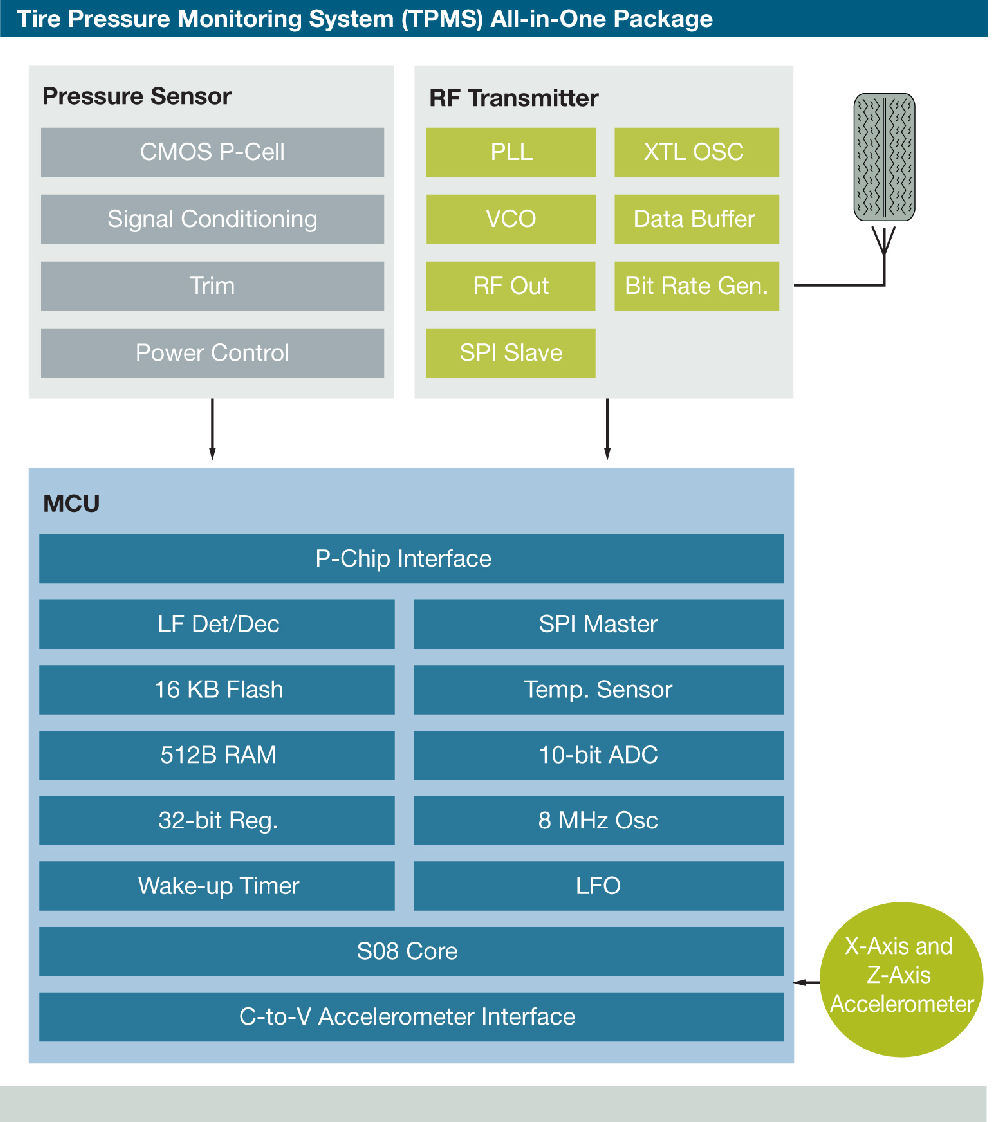

Freescale Semiconductor has introduced what it claims to be the industry's first tire pressure monitoring system (TPMS) featuring a capacitive pressure sensor designed for ultra-low power consumption and precise sensing. "By utilizing capacitive sensor technology, we achieve low power consumption alongside a compact size, and we can now offer a two-axis accelerometer with self-testing capabilities, which is unique," stated Mark Shaw, a senior member of the technical staff at Freescale. Targeted at automobiles and medium- to heavy-duty trucks, the MPXY8300 system-in-package device delivers a highly integrated and cost-effective solution that combines a pressure sensor, an 8-bit microcontroller (MCU), a 2-axis accelerometer, and a radio frequency (RF) transmitter within a 20-pin SOIC wide body package. A significant factor in its development is the National Highway Traffic Safety Administration's (NHTSA) regulations mandating that all new vehicles weighing up to 10,000 pounds must incorporate TPMS technology by model year 2008. Similar safety regulations are anticipated in Europe and Asia-Pacific. According to Strategy Analytics, automotive safety is the primary growth driver for automotive electronics systems, with legislation propelling growth in areas such as TPMS and occupant detection. While the NHTSA regulation is fundamental and lacks specific standards for TPMS systems, the demand for greater product differentiation is pushing the need for higher accuracy, precision, and flexibility, noted Eric Caron, product marketing for TPMS at Freescale. The MPXY8300 TPMS solution is engineered to assist drivers in maintaining proper tire pressure by promptly alerting them when any individual tire (including the spare) is not at the optimal pressure level. Designed for wheel-mounted applications, the MPXY8300 system provides accurate, real-time tire pressure measurements through direct monitoring at each wheel, complemented by an integrated accelerometer for motion detection. Enhancing the device's flexibility, the system can be programmed to transmit measurements at specific tire rotation speeds and even when the tires are stationary, as indicated by Freescale. Key components of the MPXY8300 system-in-package device include pressure and temperature sensors for tire pressure compensation, an XZ-axis accelerometer, an RF transmitter with an integrated charge pump operating at 315/434 MHz, a low-frequency input for receiving diagnostic commands, and an 8-bit MCU with 512 bytes of RAM, 16 KB of flash memory (8 KB dedicated to firmware), alongside various low-power timing functions. The design incorporates several low-power techniques aimed at extending battery life beyond the ten-year requirement. Additional notable features comprise two pressure range options of 100 to 800 kPa for passenger cars and 100 to 1500 kPa for heavy-duty trucks, multiple baud rate and modulation schemes, a low-power wake-up timer, a periodic reset driver, and an integrated filter design for media protection in harsh vehicle environments. In addition to the advantages of a single-chip solution, which lowers costs and simplifies development time, the Freescale product can be easily adapted for various applications and is available in multiple versions. "It is a single package solution that minimizes size, cost, and development time. It is also highly flexible compared to existing market offerings; it can fulfill all necessary requirements. We provide all the routines for more complex measurement tasks, compensation, and addressing hardware challenges," Shaw stated. "By leveraging our expertise and capacity in MEMS technology and applying it to pressure and acceleration for TPMS, we can deliver a product with a dual-axis accelerometer. We can also offer various levels of complexity, allowing customers different implementation options from basic to very sophisticated systems."

The MPXY8300 TPMS is designed to enhance vehicle safety by ensuring optimal tire pressure, which is critical for vehicle performance and fuel efficiency. The integration of a capacitive pressure sensor allows for accurate sensing while consuming minimal power, making it ideal for long-term applications in vehicles. The incorporation of an 8-bit MCU facilitates efficient processing of sensor data, enabling real-time monitoring and communication with the vehicle's onboard systems. The dual-axis accelerometer not only aids in motion detection but also contributes to the overall functionality of the TPMS by providing additional data that can be used for vehicle dynamics monitoring. The RF transmitter ensures reliable communication of tire pressure data to the vehicle's dashboard or monitoring system, enhancing driver awareness of tire conditions. The system's ability to operate under varying conditions, including when the tires are stationary, reflects its advanced design and adaptability to real-world scenarios. The MPXY8300 serves as a vital component in the growing field of automotive electronics, where safety and efficiency are paramount.Freescale Semiconductor has unveiled at the Freescale Technology Forum in Tokyo what it says is the industry`s first tire pressure monitoring system (TPMS) containing a capacitive pressure sensor for ultra-low-power consumption and precise sensing. "By using capacitive sensor technology, in addition to the small size, we get low power consumption, and we can now provide a two-axis accelerometer with self-testing, which is unique, " said Mark Shaw, senior member technical staff at Freescale. Designed for automobiles and medium- to heavy-duty trucks, the MPXY8300 system-in-package device provides a highly integrated and low-cost system that combines a pressure sensor, an 8-bit microcontroller (MCU), 2-axis accelerometer and radio frequency (RF) transmitter in a 20-pin SOIC wide body package.

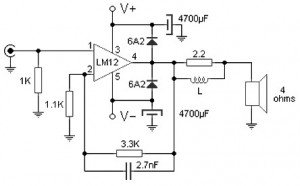

(See diagram. ) A key driver behind its development is the National Highway Traffic Safety Administration`s (NHTSA) regulations that require all new vehicles weighing up to 10, 000 pounds to include TPMS technology by the model year 2008. Similar safety regulations are expected in Europe and Asia-Pacific. Automotive safety is the number one growth driver for automotive electronics systems, according to Strategy Analytics, with legislation driving safety growth in areas of TPMS and occupant detection.

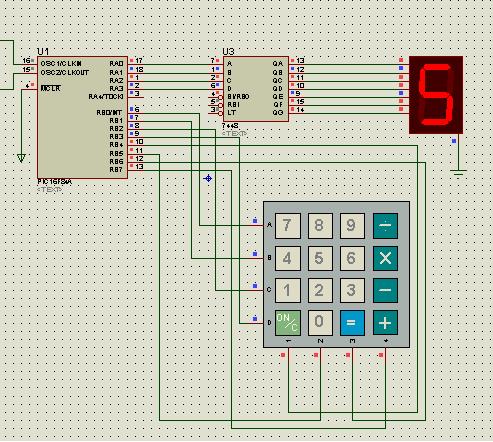

(See automotive safety growth chart and market size. ) While the NHTSA regulation is very basic and there are no standards for TPMS systems, the need for greater product differentiation is driving requirements for higher accuracy, higher precision and more flexibility, said Eric Caron, product marketing for TPMS at Freescale. The MPXY8300 TPMS solution is designed to help drivers maintain proper tire pressure by instantly notifying them when any individual tire (including the spare) is not at the optimal pressure level.

Engineered for wheel-mounted applications, the MPXY8300 system offers precise, real-time tire pressure measurement using direct monitoring at each wheel together with an integrated accelerometer for motion detection. Making the device more flexible, the system can be programmed to transmit measurements at certain tire rotation speeds and even when the tires are not rotating at all, said Freescale.

Key components of the MPXY8300 system-in-package device include the pressure and temperature sensors for compensating tire pressure, XZ-axis accelerometer, RF transmitter with integrated charge pump at 315/434 MHz, low-frequency input for receiving diagnostic commands, and an 8-bit MCU with 512b RAM, 16 KB flash (8KB dedicated to firmware) and multiple low-power timing functions. It also incorporates several low-power techniques to help extend the battery-life beyond the ten-year requirements.

Other key features include two pressure range options of 100 to 800 kPa for passenger cars and 100 to 1500 kPa for heavy-duty trucks, multiple baud rate and modulation scheme, a low-power wake-up timer and periodic reset driver, and an integrated filter design for media protection in harsh vehicle environments. In addition to the benefit of using a single-chip solution, which reduces cost and eases development time, the Freescale product can be easily modified by application and is available in several versions.

"It`s a single package solution that reduces size, cost and development time. It`s also highly flexible compared to what you see in the market; you can do every thing with this part that we see required. We also provide all the routines to do the more complicated tasks of making the measurement and compensating it, and handling some of the hardware issues, " said Shaw.

"By taking our expertise and capacity in MEMS and applying it to pressure and acceleration for TPMS we can provide a product with a dual-axis accelerometer. We can also provide it with a variety of levels so customers have different ways of implementing their system from basic to very complex, " s

🔗 External reference

The MPXY8300 TPMS is designed to enhance vehicle safety by ensuring optimal tire pressure, which is critical for vehicle performance and fuel efficiency. The integration of a capacitive pressure sensor allows for accurate sensing while consuming minimal power, making it ideal for long-term applications in vehicles. The incorporation of an 8-bit MCU facilitates efficient processing of sensor data, enabling real-time monitoring and communication with the vehicle's onboard systems. The dual-axis accelerometer not only aids in motion detection but also contributes to the overall functionality of the TPMS by providing additional data that can be used for vehicle dynamics monitoring. The RF transmitter ensures reliable communication of tire pressure data to the vehicle's dashboard or monitoring system, enhancing driver awareness of tire conditions. The system's ability to operate under varying conditions, including when the tires are stationary, reflects its advanced design and adaptability to real-world scenarios. The MPXY8300 serves as a vital component in the growing field of automotive electronics, where safety and efficiency are paramount.Freescale Semiconductor has unveiled at the Freescale Technology Forum in Tokyo what it says is the industry`s first tire pressure monitoring system (TPMS) containing a capacitive pressure sensor for ultra-low-power consumption and precise sensing. "By using capacitive sensor technology, in addition to the small size, we get low power consumption, and we can now provide a two-axis accelerometer with self-testing, which is unique, " said Mark Shaw, senior member technical staff at Freescale. Designed for automobiles and medium- to heavy-duty trucks, the MPXY8300 system-in-package device provides a highly integrated and low-cost system that combines a pressure sensor, an 8-bit microcontroller (MCU), 2-axis accelerometer and radio frequency (RF) transmitter in a 20-pin SOIC wide body package.

(See diagram. ) A key driver behind its development is the National Highway Traffic Safety Administration`s (NHTSA) regulations that require all new vehicles weighing up to 10, 000 pounds to include TPMS technology by the model year 2008. Similar safety regulations are expected in Europe and Asia-Pacific. Automotive safety is the number one growth driver for automotive electronics systems, according to Strategy Analytics, with legislation driving safety growth in areas of TPMS and occupant detection.

(See automotive safety growth chart and market size. ) While the NHTSA regulation is very basic and there are no standards for TPMS systems, the need for greater product differentiation is driving requirements for higher accuracy, higher precision and more flexibility, said Eric Caron, product marketing for TPMS at Freescale. The MPXY8300 TPMS solution is designed to help drivers maintain proper tire pressure by instantly notifying them when any individual tire (including the spare) is not at the optimal pressure level.

Engineered for wheel-mounted applications, the MPXY8300 system offers precise, real-time tire pressure measurement using direct monitoring at each wheel together with an integrated accelerometer for motion detection. Making the device more flexible, the system can be programmed to transmit measurements at certain tire rotation speeds and even when the tires are not rotating at all, said Freescale.

Key components of the MPXY8300 system-in-package device include the pressure and temperature sensors for compensating tire pressure, XZ-axis accelerometer, RF transmitter with integrated charge pump at 315/434 MHz, low-frequency input for receiving diagnostic commands, and an 8-bit MCU with 512b RAM, 16 KB flash (8KB dedicated to firmware) and multiple low-power timing functions. It also incorporates several low-power techniques to help extend the battery-life beyond the ten-year requirements.

Other key features include two pressure range options of 100 to 800 kPa for passenger cars and 100 to 1500 kPa for heavy-duty trucks, multiple baud rate and modulation scheme, a low-power wake-up timer and periodic reset driver, and an integrated filter design for media protection in harsh vehicle environments. In addition to the benefit of using a single-chip solution, which reduces cost and eases development time, the Freescale product can be easily modified by application and is available in several versions.

"It`s a single package solution that reduces size, cost and development time. It`s also highly flexible compared to what you see in the market; you can do every thing with this part that we see required. We also provide all the routines to do the more complicated tasks of making the measurement and compensating it, and handling some of the hardware issues, " said Shaw.

"By taking our expertise and capacity in MEMS and applying it to pressure and acceleration for TPMS we can provide a product with a dual-axis accelerometer. We can also provide it with a variety of levels so customers have different ways of implementing their system from basic to very complex, " s

🔗 External reference