Fun with LEDs

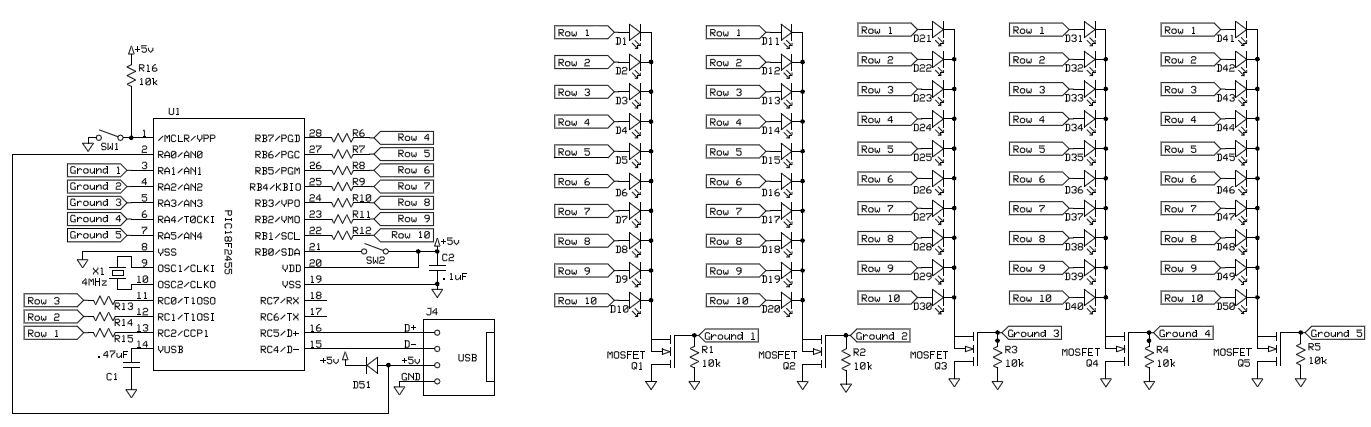

Recently, LED strips were purchased from a local electronics shop to replace spotlights in the kitchen. The chosen strips emit a cold white light, which is effective for nighttime illumination, resembling a moonlight hue. Operating at 12V, they consume approximately 0.25A per meter. After installation, automation circuits were developed to enhance functionality while utilizing available components. New white LEDs were also installed in hallway spotlights along with a light sensor. Passive Infrared (PIR) sensors were integrated to activate the kitchen and bathroom lights upon detecting motion. These sensors, utilizing a BISS0001 integrated circuit, output a 3.3V signal for an adjustable duration when motion is sensed. The overall results have been satisfactory, providing adequate lighting in the hallway at night, a small automatic light in the bathroom, and a sufficiently bright kitchen light for daytime use. The gradual dimming effect upon turning off the lights offers visual appeal and serves as a warning if someone remains still long enough to trigger the light's shutdown. A solution to achieve a similar effect upon activation, without delay, is still being sought. The circuit responsible for the hallway lights includes a transistor (T2) that disables when it becomes dark, allowing another transistor (T1) to activate the LEDs. The light threshold is set by a voltage divider composed of a photoresistor and a potentiometer. A simple current-limiting resistor was favored over a constant current supply, as a maximum of 100mA (set with resistor R3) poses no risk of thermal runaway. As the PIR sensors cannot directly power the LED strip, a transistor amplifier was employed for the bathroom light, which consists of a 20cm light strip drawing about 50mA, providing sufficient illumination for nighttime bathroom use without activating the main bright light. The transistor is driven through a diode for instant activation, while a capacitor (C1) discharges through resistor R2, resulting in a gradual dimming effect over several seconds. Initially, a similar gradual activation effect was desired, but the time needed to charge the capacitor to the threshold voltage resulted in an undesirable delay. For the kitchen strip, both dim lighting during darkness and motion sensor activation were required. The light sensor circuit was simplified, as 10mA (limited by resistor R7) through the strip proved adequate for nighttime visibility. A single transistor sufficed for this application. The light sensor activation circuit was more complex due to available components, necessitating a transistor capable of handling approximately 0.5A and dissipating heat during the gradual shutdown. The only suitable transistor available was an IRF9530, which required an additional transistor for driving. As in the previous circuit, rapid activation was prioritized, but the light still dims over a few seconds. Resistor R6 was initially 150K, but this caused delays in activation and may need to be shorted. Installation conditions required the use of an aluminum profile to secure the strip, resulting in a two-piece assembly. To ensure safety, the strips were coated with several layers of acrylic for insulation, given that the power supply is isolated from the mains.

The described circuit employs several components to achieve automated lighting control in the kitchen and bathroom, enhancing convenience and safety. The use of LED strips provides energy-efficient illumination with a long lifespan. The integration of PIR sensors allows for motion detection, ensuring lights are only activated when needed, thus conserving energy. The gradual dimming feature enhances user experience by providing a soft transition to darkness, which is particularly beneficial in low-light environments. The choice of components, such as the BISS0001 IC for the PIR sensors and the IRF9530 for driving the LED strips, reflects a careful consideration of available materials while maintaining functionality. The circuit design incorporates a voltage divider to set the light threshold, ensuring that the lights activate appropriately based on ambient light conditions. The use of a simple current-limiting resistor instead of a constant current supply reduces complexity and potential thermal issues, making the circuit more reliable. Overall, this automated lighting system exemplifies a practical approach to home illumination, utilizing readily available components to create a functional and efficient solution.I have recently stumbled upon some LED strip at my local electronics shop and decided to give them a try. I bought some which I used to replace the spot lights in the kitchen. It is cold white, which is surprisingly good, especially for night time illumination (think moonlight like hue).

It works at 12V and consumes about 0. 25A per meter. After in stalling the strip, some automation proved to be necessary, and so the following circuits were built. The goal in mind was to keep things as simple as possible and use only parts I had at hand, which is why the solution might not be the best.

The hallway spotlights got new white LEDs as well and a light sensor. Tiny PIR sensors will turn on the lights in the kitchen and bathroom when someone comes in range. The sensors are rather popular modules using a BISS0001 IC; they provide a 3. 3V level for an adjustable time when motion is detected. Overall the results are great. The hallway is lit at night, the there is a small automatic light for the bathroom and the automatic kitchen light is bright enough even for day time illumination of the sink and counter. The slow turn off provides both a visually pleasing effect and a warning in case someone stood still long enough to make the light go off.

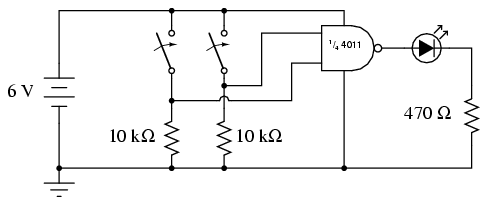

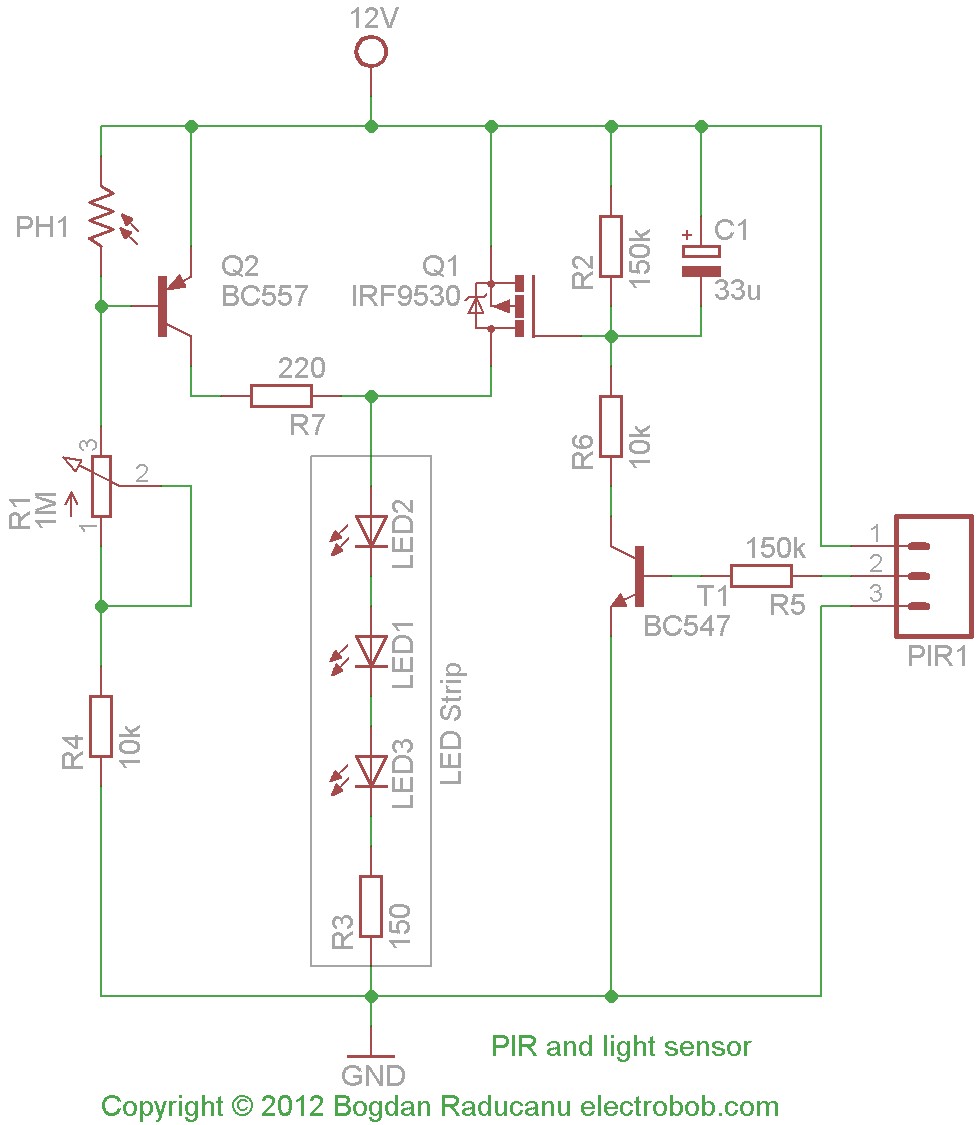

I am still looking for a simple solution to produce the same effect on turn on, but without the delay. The circuit is used to turn on the hallway lights. T2 will turn off when it is dark enough, allowing T1 to turn ON and light up the LEDs. The threshold is determined by the divider formed with a photo resistor and a potentiometer. I gave up using a constant current supply in the favor of a simple current limiting resistor because at around 100mA of current (set with R3) there is no danger of thermal runaway.

The PIR sensors themselves cannot turn on a strip of LEDs so, for the bathroom light I have used a simple transistor amplifier. The light is made up of just 20cm of light strip consuming about 50mA, but it produces enough light for a sleepy person to be able to use the bathroom without the need of the bright waking main light.

Driving the transistor through the diode insures and instant on, but once the PIR turns off, C1 will discharge through R2 slowly turning off the LEDs during a few seconds. My initial desire was to have the same effect at turn on, but the time required to charge the capacitor up to the threshold voltage will produce a few seconds of delay which in practice causes undesirable effect.

For the kitchen strip I wanted both of the functions above: a dim light when it gets dark and motion sensor turn on. The circuit is not exactly the combination of the two since I had to take into account different things.

First, the light sensor was simplified since I found out that 10mA (limited by R7) worth of current through the strip produce enough light for the night (yes, that little current makes the strip give enough light to see what it is in front of me). This means that a single transistor is enough. The light sensor turn on circuit became a little more complicated, mostly due to the parts I had available.

The transistor has to drive more current (close to 0. 5A) and support the heating produced during the slow turn off when it will dissipate more power. The only suitable transistor I had available was an IRF9530. This required another transistor to drive it. Just like the previous circuit, turn on carried as fast as possible, but the light turns off in a few seconds. R6 was initially 150K, until I discovered that this produces a delay in turn on. It may be simply shorted. The mounting conditions forced me to use an aluminum profile for first fixing the strip onto it and to split the whole thing in two pieces.

Unfortunately, Murphy caught in: Other notes: The strips were sprayed with a few layers of acrylic to ensure good insulation, just for added safety, as the power supply is insulated from the mains. 🔗 External reference

The described circuit employs several components to achieve automated lighting control in the kitchen and bathroom, enhancing convenience and safety. The use of LED strips provides energy-efficient illumination with a long lifespan. The integration of PIR sensors allows for motion detection, ensuring lights are only activated when needed, thus conserving energy. The gradual dimming feature enhances user experience by providing a soft transition to darkness, which is particularly beneficial in low-light environments. The choice of components, such as the BISS0001 IC for the PIR sensors and the IRF9530 for driving the LED strips, reflects a careful consideration of available materials while maintaining functionality. The circuit design incorporates a voltage divider to set the light threshold, ensuring that the lights activate appropriately based on ambient light conditions. The use of a simple current-limiting resistor instead of a constant current supply reduces complexity and potential thermal issues, making the circuit more reliable. Overall, this automated lighting system exemplifies a practical approach to home illumination, utilizing readily available components to create a functional and efficient solution.I have recently stumbled upon some LED strip at my local electronics shop and decided to give them a try. I bought some which I used to replace the spot lights in the kitchen. It is cold white, which is surprisingly good, especially for night time illumination (think moonlight like hue).

It works at 12V and consumes about 0. 25A per meter. After in stalling the strip, some automation proved to be necessary, and so the following circuits were built. The goal in mind was to keep things as simple as possible and use only parts I had at hand, which is why the solution might not be the best.

The hallway spotlights got new white LEDs as well and a light sensor. Tiny PIR sensors will turn on the lights in the kitchen and bathroom when someone comes in range. The sensors are rather popular modules using a BISS0001 IC; they provide a 3. 3V level for an adjustable time when motion is detected. Overall the results are great. The hallway is lit at night, the there is a small automatic light for the bathroom and the automatic kitchen light is bright enough even for day time illumination of the sink and counter. The slow turn off provides both a visually pleasing effect and a warning in case someone stood still long enough to make the light go off.

I am still looking for a simple solution to produce the same effect on turn on, but without the delay. The circuit is used to turn on the hallway lights. T2 will turn off when it is dark enough, allowing T1 to turn ON and light up the LEDs. The threshold is determined by the divider formed with a photo resistor and a potentiometer. I gave up using a constant current supply in the favor of a simple current limiting resistor because at around 100mA of current (set with R3) there is no danger of thermal runaway.

The PIR sensors themselves cannot turn on a strip of LEDs so, for the bathroom light I have used a simple transistor amplifier. The light is made up of just 20cm of light strip consuming about 50mA, but it produces enough light for a sleepy person to be able to use the bathroom without the need of the bright waking main light.

Driving the transistor through the diode insures and instant on, but once the PIR turns off, C1 will discharge through R2 slowly turning off the LEDs during a few seconds. My initial desire was to have the same effect at turn on, but the time required to charge the capacitor up to the threshold voltage will produce a few seconds of delay which in practice causes undesirable effect.

For the kitchen strip I wanted both of the functions above: a dim light when it gets dark and motion sensor turn on. The circuit is not exactly the combination of the two since I had to take into account different things.

First, the light sensor was simplified since I found out that 10mA (limited by R7) worth of current through the strip produce enough light for the night (yes, that little current makes the strip give enough light to see what it is in front of me). This means that a single transistor is enough. The light sensor turn on circuit became a little more complicated, mostly due to the parts I had available.

The transistor has to drive more current (close to 0. 5A) and support the heating produced during the slow turn off when it will dissipate more power. The only suitable transistor I had available was an IRF9530. This required another transistor to drive it. Just like the previous circuit, turn on carried as fast as possible, but the light turns off in a few seconds. R6 was initially 150K, until I discovered that this produces a delay in turn on. It may be simply shorted. The mounting conditions forced me to use an aluminum profile for first fixing the strip onto it and to split the whole thing in two pieces.

Unfortunately, Murphy caught in: Other notes: The strips were sprayed with a few layers of acrylic to ensure good insulation, just for added safety, as the power supply is insulated from the mains. 🔗 External reference