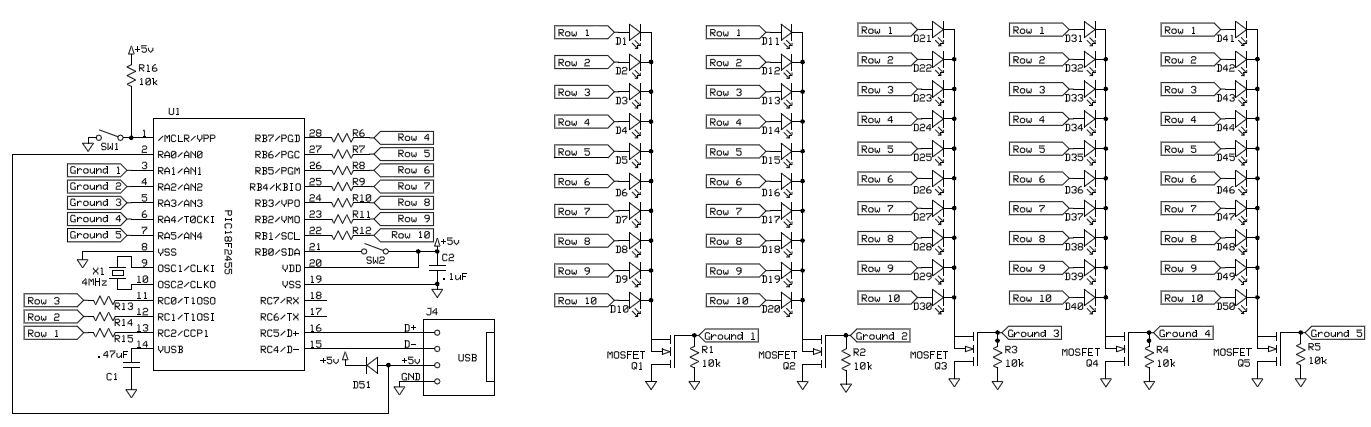

LED control system for 40 LEDs using a single PIC

To synchronize the display for persistence of vision, the PIC must track the time between successive rotations. Various magnetic sensors were evaluated for this purpose. Ultimately, a reed switch and magnet were selected for timing control, replacing an initially considered Hall effect sensor. The Hall effect sensor exhibited excessive sensitivity to the magnet, resulting in noise and an oscillating signal when observed on an oscilloscope. In contrast, the reed switch, while slower, provided a smooth and stable signal without noise. However, contact bounce issues were encountered, which affected the switch's performance. The magnet was affixed to an L-connector on one side of the mechanical system, while the reed switch was soldered onto the PCB. This arrangement ensured that the switch passed beneath the magnet with each rotation. When the magnet is positioned above the reed switch, the internal leads of the switch connect, allowing voltage to briefly flow to port RB0 on the PIC.

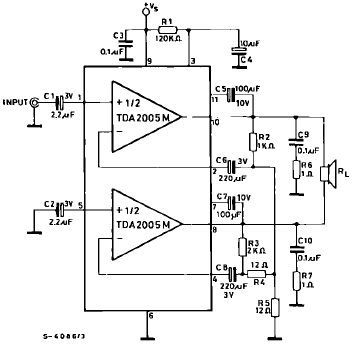

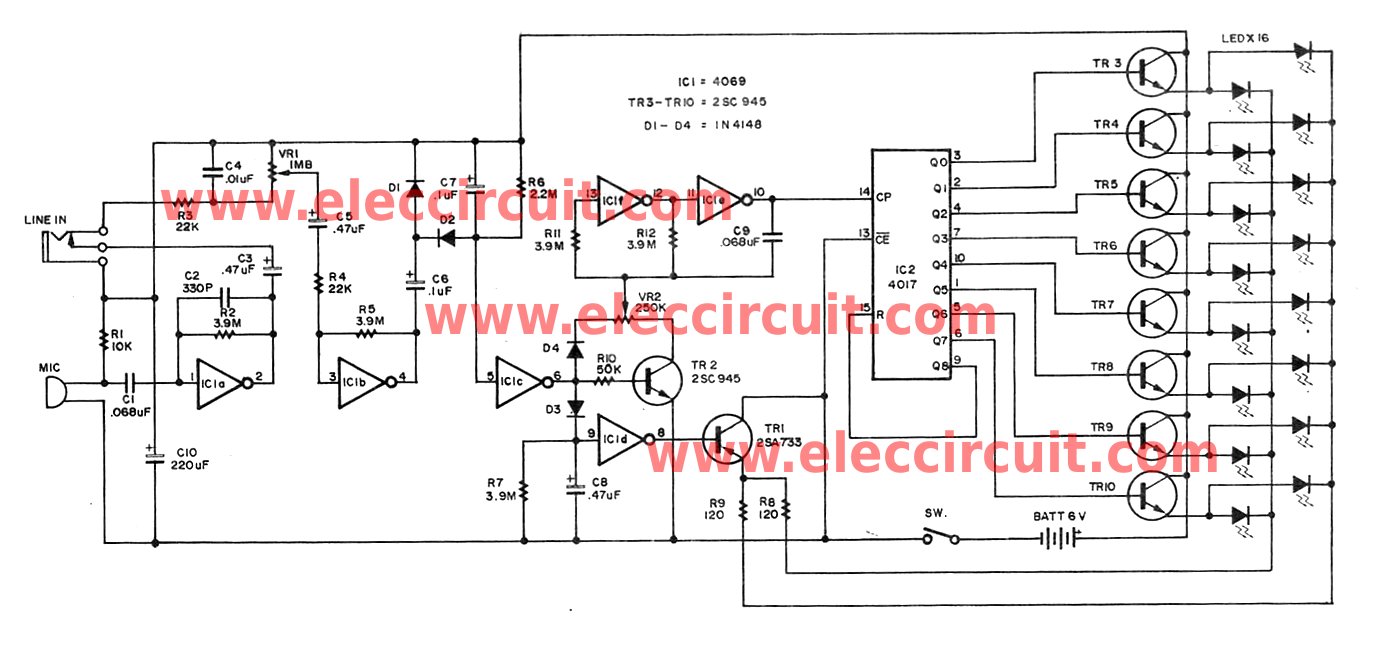

The circuit design effectively utilizes a multiplexing technique to control the 40 LEDs, allowing for a significant reduction in the number of required microcontroller pins. The n-type MOSFET serves as a low-side switch for each column, enabling the microcontroller to ground the LEDs selectively. This setup minimizes power consumption and allows for dynamic control of the LED display.

The reed switch, chosen for its reliability over the Hall effect sensor, simplifies the timing mechanism. The physical arrangement ensures that the reed switch is activated precisely once per rotation of the mechanical system, which is critical for maintaining the correct timing of the LED display. The design also addresses potential contact bounce by ensuring that the mechanical movement is smooth and consistent, which is essential for accurate timing and display performance.

In summary, the circuit effectively combines LED control through multiplexing, reliable timing using a reed switch, and careful design considerations to mitigate issues such as noise and contact bounce, resulting in a functional and visually appealing LED display system.In order to control 40 LEDs with a single PIC 18F2455 microcontroller, we broke the LEDs into a system of four columns containing 10 LED rows. Each of the 10 LEDs in a column was connected to a pin on the PIC. The grounds of all LEDs in a column were connected, with ground controlled by a n-type MOSFET transistor.

Only when the input to the transistor was set high was a given column of LEDs grounded; we were able to achieve the semblance of a constant display by quickly cycling between which LED posts are controlled.

In order to time the display properly to achieve persistence of vision, the PIC needs to record the time between successive rotations. To do this in our project, we investigated various magnetic sensors. In the end, we decided to control timing with a reed switch and magnet (we were originally using a Hall effect sensor). The Hall effect sensor was so sensitive to the magnet that it was susceptible to noise and showed an oscillating signal when we measured it with an oscilloscope. The reed switch is slower, so the signal was smooth and without noise.

Nevertheless, we encountered issues potentially due to contact bounce which interfered with the performance of the switch. We put the magnet onto an L-connector on one side of the mechanical system and soldered the reed switch onto the PCB so that once every rotation it passed underneath the magnet. When the magnet is above the reed switch, the two leads inside it connect, and voltage can briefly pass through the switch to port RB0 on the PIC.

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713