hardware aspects of moving message

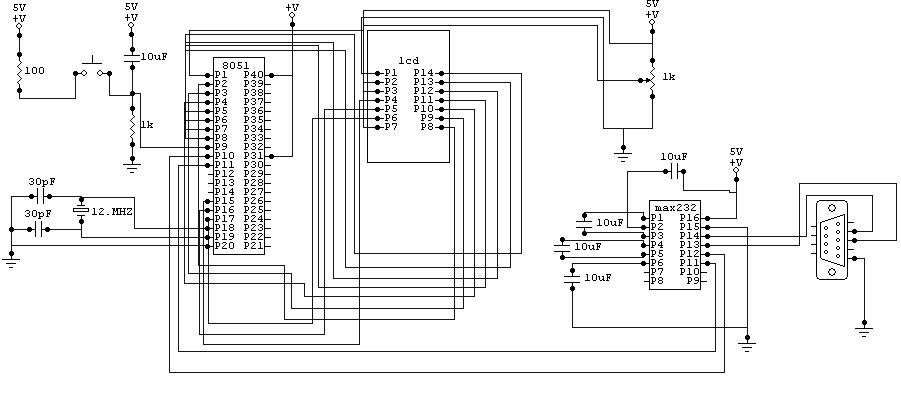

The moving message will be displayed on the LCD, which will be controlled through a microcontroller. The message will be sent by a computer using RS232. The circuit diagram of the moving message display is shown in this post, and the entire process is discussed here. The microcontroller is programmed to control the LCD through an interface. An eight-bit interface between the LCD and microcontroller is programmed to transfer the data to be written on the LCD display screen. Additionally, three output pins of the microcontroller are used to generate control signals for the LCD. These control signals are generated in accordance with the timing diagram discussed in previous chapters. The project consists of three components: the LCD, microcontroller, and serial port. These components have been discussed independently, and a complete picture necessitates linking them logically and through hardware connections. The serial port is connected to the microcontroller to enable the end user to pass a desired string to the LCD in real-time. An interface between the serial port and the microcontroller is required for data transfer. A variable baud rate is generated by the microcontroller to synchronize data transfer between the two ends. The connectivity can be analyzed through the hardware diagram at the end of the chapter. The microcontroller connects with the LCD using an 8-bit interface for data transfer. Three additional pins are required to generate enable, read/write, and instruction/data signals for the LCD. These three signals form a small instruction set that allows different tasks and functionalities provided by the HD44780 LCD. The enable signal indicates to the LCD that data is available. A high-to-low edge triggers the LCD to read its data lines. The data meant for the LCD must be present and latched on the data lines before the enable signal transitions from high to low. It is important to note that the data lines for sending instructions and display data are the same; the instruction bits help differentiate between the two for the LCD. The read/write signal specifies whether the microcontroller intends to read data from or write data to the LCD's DDRAM/CGRAM. In the former case, the data lines contain the data meant for the destination in the LCD memory, and in the latter, the data lines will have the data written from the appropriate DDRAM/CGRAM. The instruction/data line specifies whether the data bus contains an instruction or data meant for the LCD. This signal, along with the instruction bits, assists the LCD in deciding which control signals to generate to fulfill the request. After sending every request, whether instruction or data, to the LCD, the microcontroller must check the busy flag of the LCD to ensure it returns to a low logic state. A high logic for the busy flag indicates that an internal operation is ongoing, during which no external instruction or data is processed. Only when the busy flag is at a logic low should the microcontroller send the next instruction or data. The busy flag is checked by configuring the LCD into read mode (setting the R/W signal to logic high) and then reading the data lines. The most significant bit (MSB) of the byte read contains the value of the busy flag. To understand these concepts, the timing diagram referenced in Chapter 2 for busy flag testing and data transfer may be utilized.

The moving message display system utilizes an LCD to present dynamic text, controlled by a microcontroller that interfaces with a computer via an RS232 serial connection. The microcontroller is programmed to manage an 8-bit data bus that connects to the LCD, allowing for efficient data transfer. The control signals generated by the microcontroller, specifically the enable, read/write, and instruction/data signals, are crucial for the operation of the LCD.

The enable signal is essential for indicating the readiness of the LCD to receive data. When the microcontroller sets this signal from high to low, the LCD captures the data present on its data lines. It is critical that the data is stable and latched before this transition occurs to ensure accurate reading. The read/write signal determines the operation mode of the LCD, allowing the microcontroller to either read from or write to the display's memory. The instruction/data line further clarifies the type of data being sent, guiding the LCD in processing the incoming information appropriately.

In practical terms, the microcontroller must monitor the busy flag of the LCD after each command to ensure that it is ready for the next operation. This is accomplished by switching the LCD into read mode and checking the status of the busy flag on the data lines. The timing diagram serves as a reference for understanding the sequence of operations and ensuring synchronization between the microcontroller and the LCD.

Overall, the integration of these components forms a cohesive system capable of displaying moving messages in real time, providing a versatile solution for various applications such as advertising, information dissemination, and interactive displays. The project exemplifies the synergy between hardware and software in embedded systems, showcasing the importance of precise timing and control in electronic design.the moving message will be display on the LCD which will be controlled through microcontroller and the message will be sent by computer using RS232. The circuit diagram of the moving message display is shown in this post and how the whole process is completed is discussed here.

The Microcontroller in this software is programmed such that it contro ls the LCD through an interface. An eight-bit interface between in the LCD and Microcontroller is programmed to transfer the data to be written on the LCD display screen. A further three out pins of the Microcontroller are used to generate control signals for the LCD. The three control signals are generated in the same pattern as discussed in the timing diagram in the previous chapters.

The project, when looked in totality, can be seen as composing of three components, namely LCD, Microcontroller and serial port. The three components have been discussed independently until now and to give a complete picture, it is necessary to link these components.

The linking is not only logical but is also translated into hardware connections. The serial port is connected to the Microcontroller to provide the end user with the functionality of passing a desired string to LCD in run time. An interface between the serial port and the Microcontroller is required for the data transfer. A variable baud rate is generated by the Microcontroller to synchronize the data transfer between the two ends.

The connectivity can be analyzed and understood by the hardware diagram at the end of the chapter. The Microcontroller connects with the LCD with an 8bit interface to for data transfer. Three further pins are required to generate enable, read/write and instruction / data signals for the LCD. These three form a small instruction set that allows different tasks and the functionality provided by the HD44 LCD.

The enable signal is used as a signal to the LCD by the Microcontroller about the availability of data. A high-to-low edge triggers the LCD into reading its data lines. The data meant for the LCD must be present and latched on the data lines before the enable signal switches from high to logic low.

It needs to be understood that data lines for sending instructions and display data are the same, the instruction bits help differentiate among the two for the LCD. The read/write signal specifies to the LCD whether the Microcontroller is intends to read data from its DDRAM/CGRAM or intends to write data to its DDRAM/CGRAM.

In the former case, the data lines contain the data meant for the destination on the LCD memory and in the latter case; the data lines will have the data written onto from the appropriate DDRAM/CGRAM. The instruction/data line specifies whether the data bus contains an instruction or data meant for the LCD.

This signal, along with the instruction bits, help LCD in deciding which control signals to generate to fulfill the request. After sending of every request, whether instruction or data, to the LCD; the Microcontroller must check for the busy flag of the LCD to return to low logic again.

A high logic for the busy flag signals that an internal operation is being carried out and during this time, no external instruction or data is entertained. Only when the busy flag is at a logic low, the Microcontroller should send the next instruction or data.

The busy flag is checked by configuring the LCD into read mode (R/W signal is set to logic high) and then reading the data lines. The MSB of the byte read contains the value of the busy flag. To understand the above concepts, the timing diagram mentioned in Chapter 2 for busy flag testing and data transfer may be used.

Hardware Aspects of Moving Message Display Project, LED BASED MOVING DISPLAY USING 8051, Scrolling Message in LED Display with 8051, 8x8 LED Matrix using 8051, A Microcontroller Based Moving Message Display, Project Help / Display Moving Message, scrolling message display usi 🔗 External reference

The moving message display system utilizes an LCD to present dynamic text, controlled by a microcontroller that interfaces with a computer via an RS232 serial connection. The microcontroller is programmed to manage an 8-bit data bus that connects to the LCD, allowing for efficient data transfer. The control signals generated by the microcontroller, specifically the enable, read/write, and instruction/data signals, are crucial for the operation of the LCD.

The enable signal is essential for indicating the readiness of the LCD to receive data. When the microcontroller sets this signal from high to low, the LCD captures the data present on its data lines. It is critical that the data is stable and latched before this transition occurs to ensure accurate reading. The read/write signal determines the operation mode of the LCD, allowing the microcontroller to either read from or write to the display's memory. The instruction/data line further clarifies the type of data being sent, guiding the LCD in processing the incoming information appropriately.

In practical terms, the microcontroller must monitor the busy flag of the LCD after each command to ensure that it is ready for the next operation. This is accomplished by switching the LCD into read mode and checking the status of the busy flag on the data lines. The timing diagram serves as a reference for understanding the sequence of operations and ensuring synchronization between the microcontroller and the LCD.

Overall, the integration of these components forms a cohesive system capable of displaying moving messages in real time, providing a versatile solution for various applications such as advertising, information dissemination, and interactive displays. The project exemplifies the synergy between hardware and software in embedded systems, showcasing the importance of precise timing and control in electronic design.the moving message will be display on the LCD which will be controlled through microcontroller and the message will be sent by computer using RS232. The circuit diagram of the moving message display is shown in this post and how the whole process is completed is discussed here.

The Microcontroller in this software is programmed such that it contro ls the LCD through an interface. An eight-bit interface between in the LCD and Microcontroller is programmed to transfer the data to be written on the LCD display screen. A further three out pins of the Microcontroller are used to generate control signals for the LCD. The three control signals are generated in the same pattern as discussed in the timing diagram in the previous chapters.

The project, when looked in totality, can be seen as composing of three components, namely LCD, Microcontroller and serial port. The three components have been discussed independently until now and to give a complete picture, it is necessary to link these components.

The linking is not only logical but is also translated into hardware connections. The serial port is connected to the Microcontroller to provide the end user with the functionality of passing a desired string to LCD in run time. An interface between the serial port and the Microcontroller is required for the data transfer. A variable baud rate is generated by the Microcontroller to synchronize the data transfer between the two ends.

The connectivity can be analyzed and understood by the hardware diagram at the end of the chapter. The Microcontroller connects with the LCD with an 8bit interface to for data transfer. Three further pins are required to generate enable, read/write and instruction / data signals for the LCD. These three form a small instruction set that allows different tasks and the functionality provided by the HD44 LCD.

The enable signal is used as a signal to the LCD by the Microcontroller about the availability of data. A high-to-low edge triggers the LCD into reading its data lines. The data meant for the LCD must be present and latched on the data lines before the enable signal switches from high to logic low.

It needs to be understood that data lines for sending instructions and display data are the same, the instruction bits help differentiate among the two for the LCD. The read/write signal specifies to the LCD whether the Microcontroller is intends to read data from its DDRAM/CGRAM or intends to write data to its DDRAM/CGRAM.

In the former case, the data lines contain the data meant for the destination on the LCD memory and in the latter case; the data lines will have the data written onto from the appropriate DDRAM/CGRAM. The instruction/data line specifies whether the data bus contains an instruction or data meant for the LCD.

This signal, along with the instruction bits, help LCD in deciding which control signals to generate to fulfill the request. After sending of every request, whether instruction or data, to the LCD; the Microcontroller must check for the busy flag of the LCD to return to low logic again.

A high logic for the busy flag signals that an internal operation is being carried out and during this time, no external instruction or data is entertained. Only when the busy flag is at a logic low, the Microcontroller should send the next instruction or data.

The busy flag is checked by configuring the LCD into read mode (R/W signal is set to logic high) and then reading the data lines. The MSB of the byte read contains the value of the busy flag. To understand the above concepts, the timing diagram mentioned in Chapter 2 for busy flag testing and data transfer may be used.

Hardware Aspects of Moving Message Display Project, LED BASED MOVING DISPLAY USING 8051, Scrolling Message in LED Display with 8051, 8x8 LED Matrix using 8051, A Microcontroller Based Moving Message Display, Project Help / Display Moving Message, scrolling message display usi 🔗 External reference