High-Voltage Pulse Generator

If you have ever wanted a high-voltage generator to create impressive lightning effects, conduct Kirlian photography experiments, or experiment with neon lights, this project is ideal. It describes a laboratory pulse generator utilizing an auto-ignition coil, capable of delivering a series of pulses up to 30,000 volts. With a few minor circuit and construction adjustments, the project can also serve as an electric fence charger, operating at a lower voltage but capable of producing much higher output current. Applications for high-voltage spikes are extensive, including studies on electromagnetic and radio-frequency interference (RFI), electrostatic discharge simulation, insulation breakdown investigations, flammability experiments, and strobe effects, among others. A DC power supply or battery is necessary, and the pulse potential can be easily adjusted by changing the supply voltage. With a 12.6-volt input, the ignition-coil model delivers its maximum pulse, but a unique multivibrator driver circuit allows operation down to a supply voltage as low as 1.5 volts, producing an output pulse of only a few hundred volts. The pulse frequency is adjustable via a front-panel control, ranging from approximately 0.3 Hz to 20 Hz. However, the ignition coil is not well-suited for the fence-charger application due to its high output resistance, typically around 10,000 ohms. Consequently, the output pulse is significantly affected by loading. A short fence may produce long sparks, which could ignite brush, while a long fence may see its output voltage drop below effective levels due to shunting by weeds, dirt, and moisture. Therefore, for the fence-charger version, the pulse frequency control must be omitted for safety reasons. The no-load output for the fence-charger option is typically 4 kV peak (kilovolts peak), or about half that value when connected to a 1-mile fence. A car battery can power the fence-charger model for approximately four months before recharging is required, assuming a recommended pulsing rate of 20 pulses per minute. While a single pulse from an ignition coil is rarely harmful, the resulting reflex muscle contraction could lead to dangerous situations, such as being unable to release a high-voltage conductor. Additionally, if a proper return circuit is not implemented, a shock could occur from contact with the primary circuit. Since the ignition coil functions as an autotransformer, the return circuit for the high-voltage pulse includes the power leads. Therefore, one side of the power supply should ideally be connected to Earth ground. This precaution helps prevent shocks from contact with power leads and reduces the risk of arcing within the power supply as the high-voltage pulse seeks the shortest return path. Applying this reasoning to the fence-charger option clarifies why a fixed pulse rate is specified, as accidental human contact with the fence wire is likely; a rate of 60 pulses per minute or less is considered safe. Given the possibility of personal contact with the power leads, a reliable ground connection is essential, as it is with any electric fence system. For maximum safety, a battery supply is recommended for the fence-charger system. If the power supply leads are reversed in either project, the current-limiting lamp, a large automotive bulb visible in the photos, will illuminate brightly to provide a warning. However, the equipment should not remain in this condition for more than a few seconds. Even if this mistake is not anticipated, including the lamp is advisable as it limits excessive surge currents that could otherwise occur under specific operating conditions, potentially damaging the power transistor.

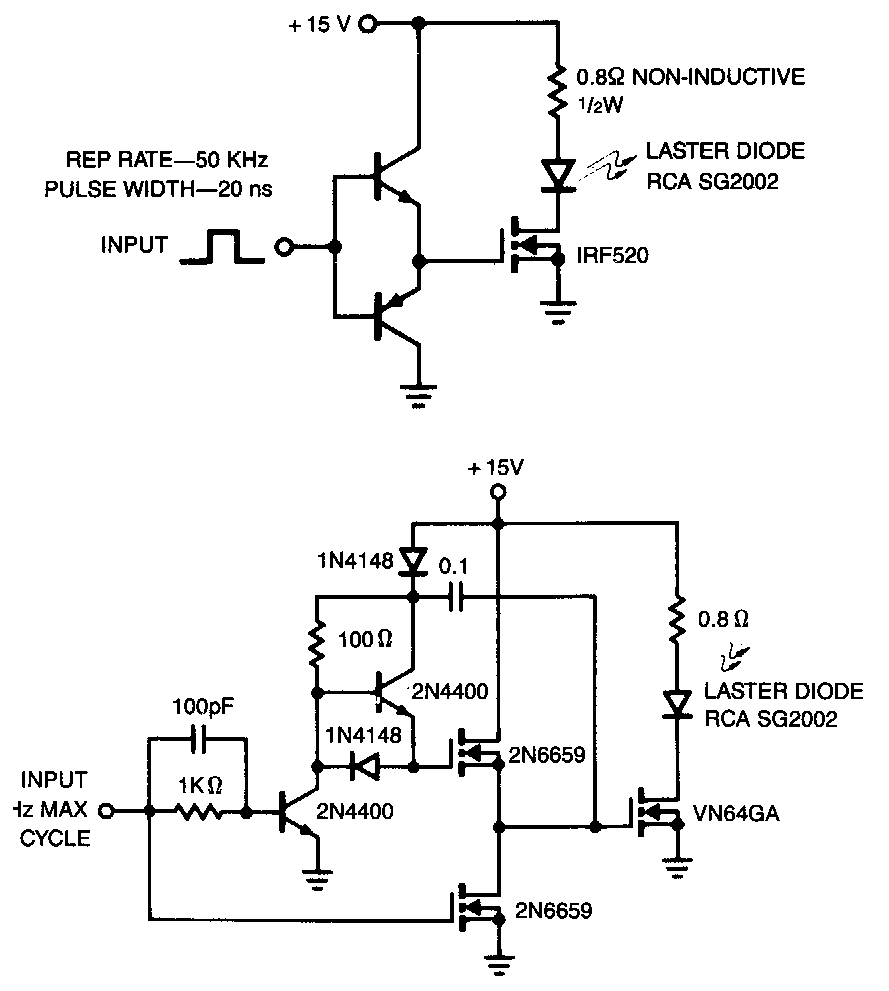

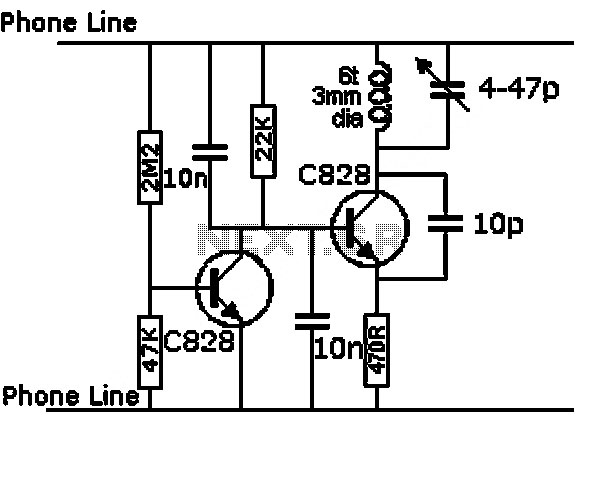

The circuit design includes a free-running variable multivibrator utilizing transistors Q1 and Q2, which drive a Darlington power amplifier, Q3. This configuration allows for the modulation of the primary current to the ignition coil, generating the desired high-voltage pulses. The multivibrator's frequency control enables the user to adjust the pulse rate, thereby tailoring the output to specific experimental needs. Additionally, the incorporation of safety features, such as the current-limiting lamp and the grounding of the power supply, enhances the overall reliability and safety of the circuit. The circuit layout should be carefully designed to minimize the risk of unintended contact with high-voltage components, reinforcing the importance of adhering to safety protocols during operation. Proper insulation and housing for the high-voltage sections are also critical to prevent accidental contact and ensure safe operation. Overall, this high-voltage generator project presents a versatile tool for various applications while emphasizing the importance of safety and proper circuit design.If you`ve ever wanted a high-voltage generator to create neat lightning effects, perform Kirlian photography experiments or play with neon lights, then this one is for you!. " We will describe a laboratory pulse generator using an auto-ignition coil and capable of delivering a train of pulses up to 30, 000 volts.

With a couple of minor circuit and construction variations, the project is suitable for use as an electric-fence charger, operating at a lower voltage, but capable of much higher output current. Applications for a high-voltage spike are numerous: electromagnetic and radio-frequency interference (RFI) studies, electrostatic-discharge simulation; investigation of insulation breakdown; flammability experiments; strobe effects; etc.

A DC power supply or battery is required, and pulse potential may be varied simply by changing the supply voltage. With a 12. 6-volt input, the ignition-coil model delivers its maximum pulse, but a unique multivibrator-driver circuit makes operation possible down to a supply voltage as low as 1.

5 volts, yielding an output pulse of only a few hundred volts. Its pulse frequency is set by a front-panel control, with a range from about 0. 3Hz to 20 Hz. An ignition coil, however, is not well adapted to the fence-charger application since its output resistance is so high: typically 10, 000 ohms. Thus its output pulse is strongly dependent on loading. With a short fence, long sparks might be struck at risk of igniting brush; while on the other hand, with a long fence, shunting by weeds or by dirt and moisture may reduce its output voltage below and effective value.

Hence for the fence-charger version the rate prf control must be omitted fro reason of safety. No-load output of the fence-charger option is typically 4 Kv pk (kilovolts peak), or about half that valuer when connected to a 1-mile fence. A car battery powers the fence-charger model for about four months before recharging is needed (at recommended pulsing rate of 20 pulses/minute).

While a single jolt from an ignition coil is itself rarely traumatic, the resulting-reflex muscle contraction could have unfortunate consequences. If a continuous train of pulses causes you to involuntarily grasp the high-voltage conductor, for instance, you might not be able to let go.

On the other hand, if proper return circuit is not provided, an equally distressing shock could be had by contact with the primary circuit. Because the ignition coil is an autotransformer, the return circuit for the high-voltage pulse includes the power leads.

Therefore, one side of the power supply should, if possible, be Earth grounded. That precaution besides shock by contact with the power leads, also precludes arcing within the power supply itself as the high-voltage pulse seeks the shortest return path. Applying that reasoning to the fence-charger option, we can see why a fixed pulse rate is specified, as there is a strong likelihood of accidental human contact with the fence wire; a rate of 60 pulses per minute or less being considered safe.

Also, since there is a good chance of personal contract with the power leads, a good ground connection is essential, as with any electric-fence system. For maximum safety, we recommend a battery supply for the fence-charger system. If you should happen to reverse the power-supply lease to either project, the current-limitation lamp, a large automotive bulb easily seen in the photos, lights brightly to warn you.

However, the equipments must not be allowed to remain in this condition for more than a few seconds. Even if you never expect to make this mistake, the lamp should be included because it limits excessive surge currents that could otherwise occur under some operating conditions and which could blow the power transistor. As shown in Fig. 1, free-running variable multivibrator Q1 and Q2 drive Darlington power amplifier Q3, which makes and breaks the primary current to c

🔗 External reference

The circuit design includes a free-running variable multivibrator utilizing transistors Q1 and Q2, which drive a Darlington power amplifier, Q3. This configuration allows for the modulation of the primary current to the ignition coil, generating the desired high-voltage pulses. The multivibrator's frequency control enables the user to adjust the pulse rate, thereby tailoring the output to specific experimental needs. Additionally, the incorporation of safety features, such as the current-limiting lamp and the grounding of the power supply, enhances the overall reliability and safety of the circuit. The circuit layout should be carefully designed to minimize the risk of unintended contact with high-voltage components, reinforcing the importance of adhering to safety protocols during operation. Proper insulation and housing for the high-voltage sections are also critical to prevent accidental contact and ensure safe operation. Overall, this high-voltage generator project presents a versatile tool for various applications while emphasizing the importance of safety and proper circuit design.If you`ve ever wanted a high-voltage generator to create neat lightning effects, perform Kirlian photography experiments or play with neon lights, then this one is for you!. " We will describe a laboratory pulse generator using an auto-ignition coil and capable of delivering a train of pulses up to 30, 000 volts.

With a couple of minor circuit and construction variations, the project is suitable for use as an electric-fence charger, operating at a lower voltage, but capable of much higher output current. Applications for a high-voltage spike are numerous: electromagnetic and radio-frequency interference (RFI) studies, electrostatic-discharge simulation; investigation of insulation breakdown; flammability experiments; strobe effects; etc.

A DC power supply or battery is required, and pulse potential may be varied simply by changing the supply voltage. With a 12. 6-volt input, the ignition-coil model delivers its maximum pulse, but a unique multivibrator-driver circuit makes operation possible down to a supply voltage as low as 1.

5 volts, yielding an output pulse of only a few hundred volts. Its pulse frequency is set by a front-panel control, with a range from about 0. 3Hz to 20 Hz. An ignition coil, however, is not well adapted to the fence-charger application since its output resistance is so high: typically 10, 000 ohms. Thus its output pulse is strongly dependent on loading. With a short fence, long sparks might be struck at risk of igniting brush; while on the other hand, with a long fence, shunting by weeds or by dirt and moisture may reduce its output voltage below and effective value.

Hence for the fence-charger version the rate prf control must be omitted fro reason of safety. No-load output of the fence-charger option is typically 4 Kv pk (kilovolts peak), or about half that valuer when connected to a 1-mile fence. A car battery powers the fence-charger model for about four months before recharging is needed (at recommended pulsing rate of 20 pulses/minute).

While a single jolt from an ignition coil is itself rarely traumatic, the resulting-reflex muscle contraction could have unfortunate consequences. If a continuous train of pulses causes you to involuntarily grasp the high-voltage conductor, for instance, you might not be able to let go.

On the other hand, if proper return circuit is not provided, an equally distressing shock could be had by contact with the primary circuit. Because the ignition coil is an autotransformer, the return circuit for the high-voltage pulse includes the power leads.

Therefore, one side of the power supply should, if possible, be Earth grounded. That precaution besides shock by contact with the power leads, also precludes arcing within the power supply itself as the high-voltage pulse seeks the shortest return path. Applying that reasoning to the fence-charger option, we can see why a fixed pulse rate is specified, as there is a strong likelihood of accidental human contact with the fence wire; a rate of 60 pulses per minute or less being considered safe.

Also, since there is a good chance of personal contract with the power leads, a good ground connection is essential, as with any electric-fence system. For maximum safety, we recommend a battery supply for the fence-charger system. If you should happen to reverse the power-supply lease to either project, the current-limitation lamp, a large automotive bulb easily seen in the photos, lights brightly to warn you.

However, the equipments must not be allowed to remain in this condition for more than a few seconds. Even if you never expect to make this mistake, the lamp should be included because it limits excessive surge currents that could otherwise occur under some operating conditions and which could blow the power transistor. As shown in Fig. 1, free-running variable multivibrator Q1 and Q2 drive Darlington power amplifier Q3, which makes and breaks the primary current to c

🔗 External reference