Homebuilt arc welder

Construct a personal arc welder. Many individuals have eagerly anticipated the release of these comprehensive plans, which are available for purchase and download in a 4.6MB PDF file for a nominal fee.

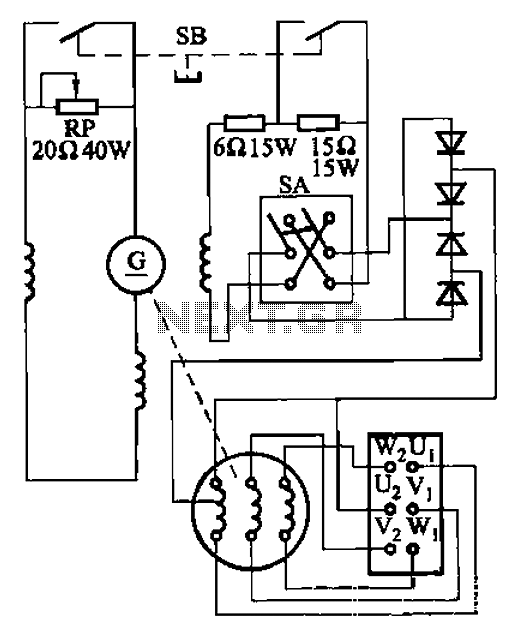

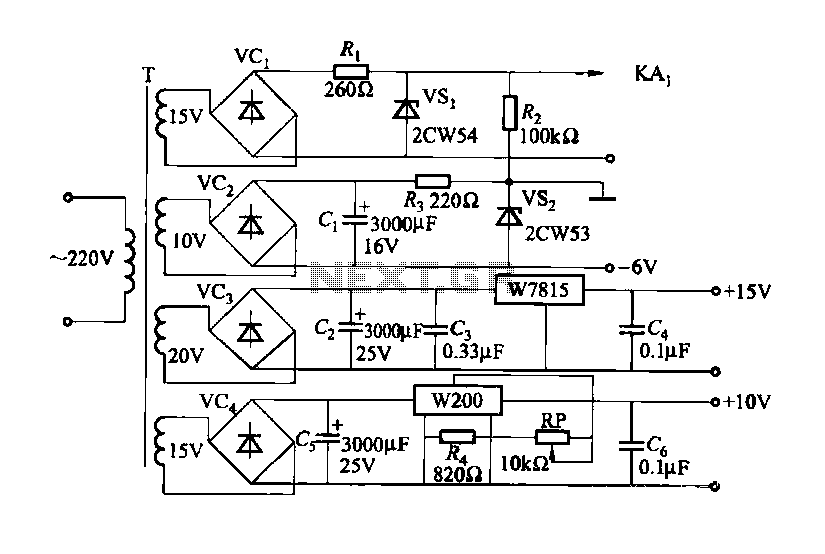

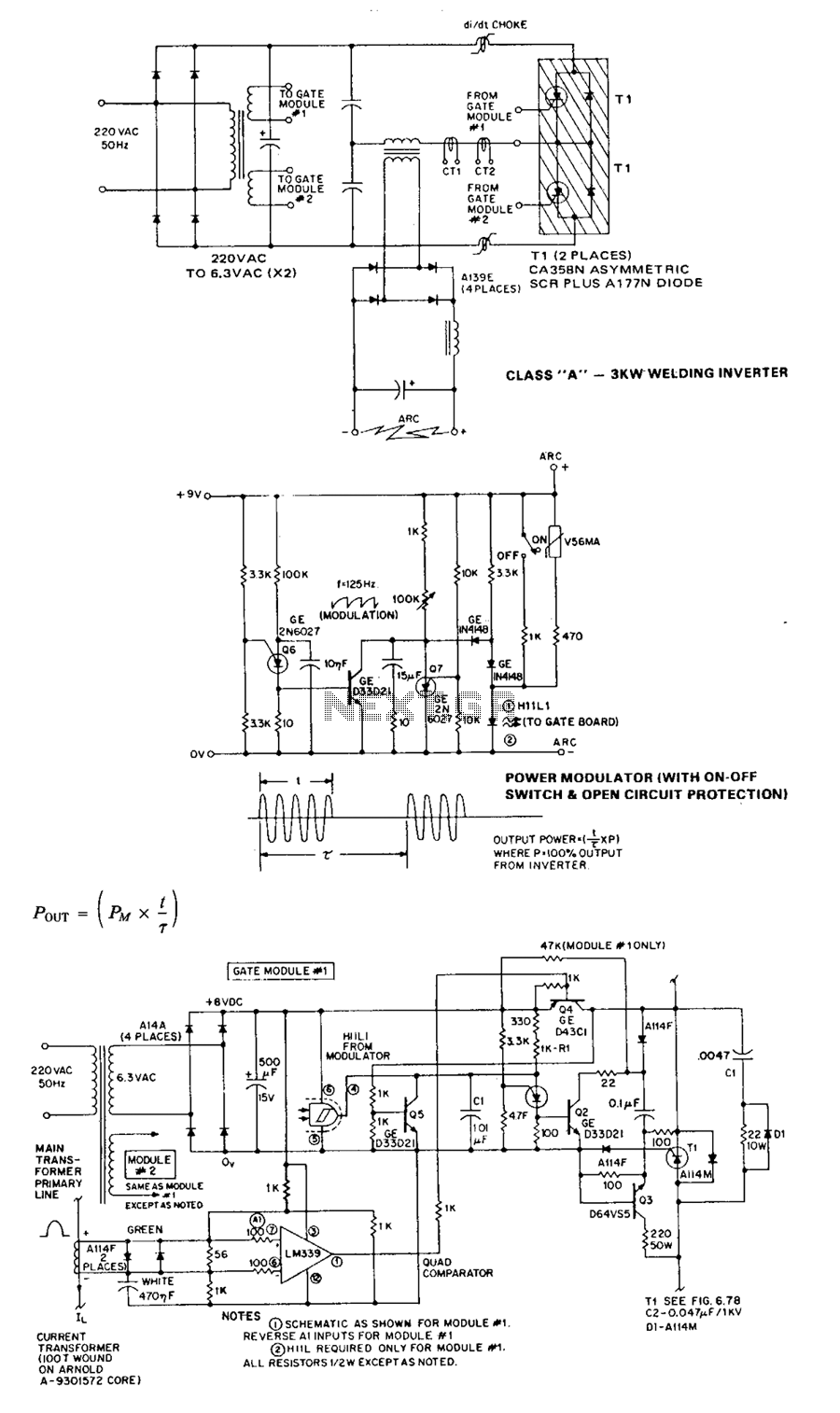

The arc welder is a vital tool in metalworking that utilizes an electric arc to melt and join metal components. The design typically includes a power supply, an electrode holder, a workpiece clamp, and a control circuit. The power supply can be either transformer-based or inverter-based, depending on the desired welding characteristics and portability.

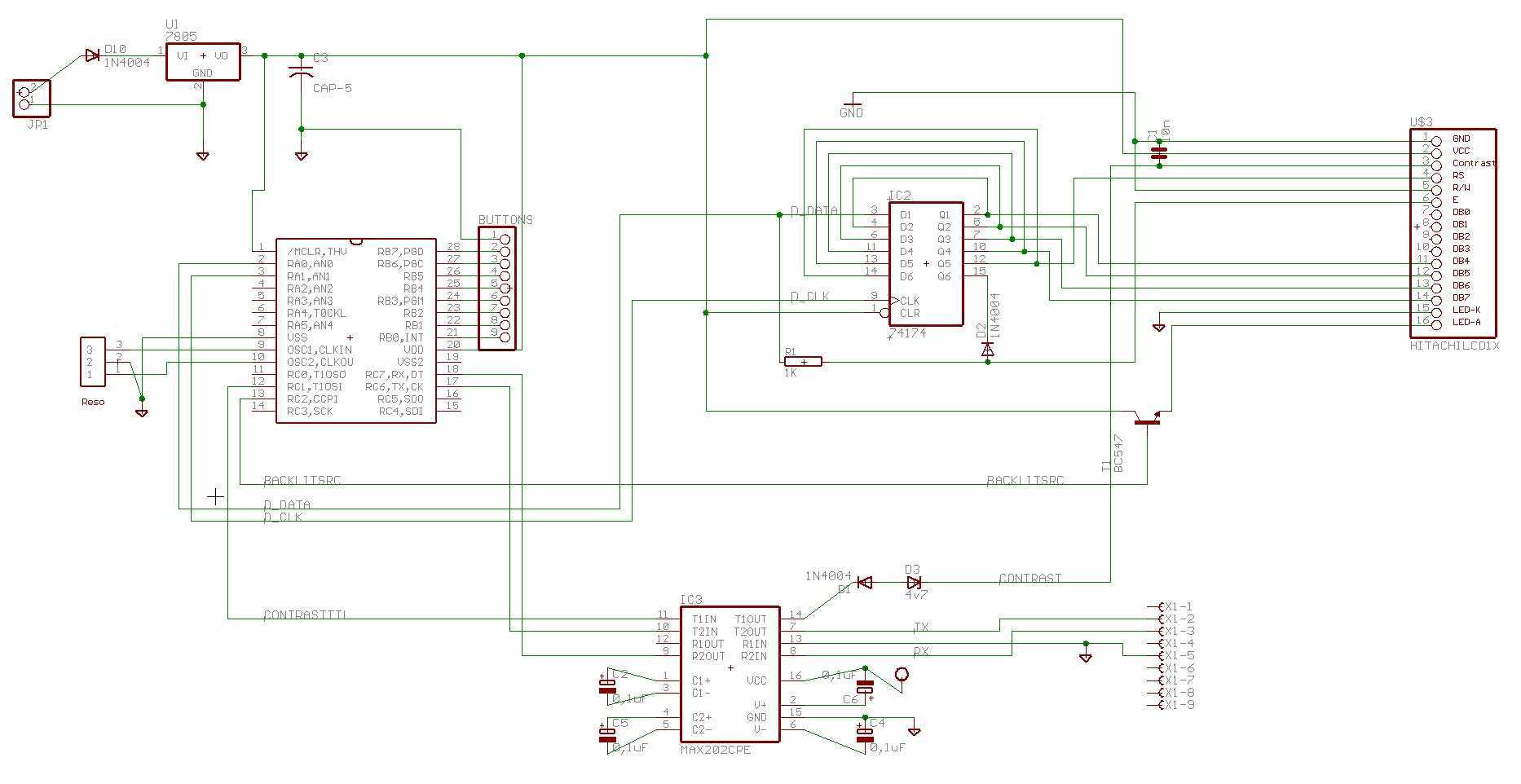

The schematic should include a transformer or inverter circuit that converts standard AC voltage to the required welding voltage. The output current can be adjusted using a variable resistor or a digital control interface. Safety features such as circuit breakers and thermal protection should be integrated to prevent damage to the welder and ensure user safety.

The electrode holder should be designed to securely grip the welding electrode while allowing for easy replacement. The workpiece clamp must provide a stable connection to the metal being welded, ensuring proper current flow. Additionally, a cooling system may be implemented to dissipate heat generated during welding, prolonging the life of the components.

The control circuit should include indicators for power status, current adjustment, and any fault conditions. Proper grounding and isolation techniques must be employed to minimize electrical hazards. Overall, the arc welder's design should prioritize efficiency, safety, and ease of use for optimal performance in various welding applications.Build your own arc welder! Many of you have been so patiently waiting the arrival of these DETAILED PLANS that you can purchase and download (4. 6MB pdf!)for a small fee. 🔗 External reference

The arc welder is a vital tool in metalworking that utilizes an electric arc to melt and join metal components. The design typically includes a power supply, an electrode holder, a workpiece clamp, and a control circuit. The power supply can be either transformer-based or inverter-based, depending on the desired welding characteristics and portability.

The schematic should include a transformer or inverter circuit that converts standard AC voltage to the required welding voltage. The output current can be adjusted using a variable resistor or a digital control interface. Safety features such as circuit breakers and thermal protection should be integrated to prevent damage to the welder and ensure user safety.

The electrode holder should be designed to securely grip the welding electrode while allowing for easy replacement. The workpiece clamp must provide a stable connection to the metal being welded, ensuring proper current flow. Additionally, a cooling system may be implemented to dissipate heat generated during welding, prolonging the life of the components.

The control circuit should include indicators for power status, current adjustment, and any fault conditions. Proper grounding and isolation techniques must be employed to minimize electrical hazards. Overall, the arc welder's design should prioritize efficiency, safety, and ease of use for optimal performance in various welding applications.Build your own arc welder! Many of you have been so patiently waiting the arrival of these DETAILED PLANS that you can purchase and download (4. 6MB pdf!)for a small fee. 🔗 External reference