Horizontal Electric Engine

A model has been constructed based on the principles of a horizontal steam engine, where the steam cylinder is substituted with an electromagnet featuring a moving core. The construction specifics are less significant, as the accompanying photos provide all necessary information. In this model, a coil replaces the cylinder, and an iron core serves as the piston of a steam engine. When the core is positioned approximately halfway into the coil and the current is activated, the core is drawn into the coil. The current is subsequently turned off automatically by the associated electronics. The core continues its movement due to the energy stored in a flywheel until it exits the coil on the opposite side. When the current is reactivated, the process repeats in the reverse direction. This results in the core (acting as a piston) moving alternately back and forth, thereby creating a reciprocating engine. Two slotted opto switches are employed to control the electromagnet and regulate its speed, as depicted in the photos. These slotted opto switches are mounted on the same printed circuit boards (PCBs) used in a Cliff Lift model, with one-third of each board removed due to the proximity of the slotted opto switches to the gearwheel in this model. The first slotted opto switch manages the on/off operation of the electromagnet current using two shutters mounted on a gearwheel (Meccano part 95b) connected to the flywheel. The second slotted opto switch measures the engine's speed using the teeth of the gearwheel. This speed data regulates the current passing through the coil. A block diagram of the system and a full circuit diagram are available, with the latter accessible for download via a provided link. The circuit utilizes IC1, a 555 timer configured in astable mode. The Reset input (pin 4) allows the Output (pin 3) to be toggled by the On/Off slotted opto switch sensor. The square wave output from the 555 timer drives a power MOSFET transistor, BUZ11. A second 555 timer, IC2, is configured in monostable mode and is triggered by the Speed slotted opto switch sensor and transistor T1. The output pulses from IC2 are integrated to produce a DC component that serves as the control voltage for IC1 (input into pin 5). This control voltage alters the frequency and duty cycle of the square wave signal from pin 3, allowing the current through the coil to vary between 0.5A and 4A, thus enabling the engine to operate at a constant speed. Speed adjustments can be made using a potentiometer to modify the monostable time period of IC2.

The model operates on the principles of electromagnetic induction, where the movement of the iron core within the coil generates a magnetic field that interacts with the current flowing through the coil. This interaction produces a force that drives the core in a reciprocating motion, akin to the operation of a steam engine but utilizing electrical energy instead of thermal energy.

The use of slotted opto switches provides precise control over the electromagnet's operation, allowing for real-time feedback and adjustment of the engine's speed. The integration of the 555 timers into the circuit provides a reliable means of generating the necessary control signals. The astable configuration of IC1 allows for continuous operation, while the monostable configuration of IC2 enables the detection of speed changes and the adjustment of the control voltage accordingly.

The circuit design emphasizes modularity and adaptability, as evidenced by the use of standard components such as the 555 timer and the power MOSFET, which are widely available and easy to integrate into various applications. The ability to adjust the speed via a potentiometer enhances the model's versatility, making it suitable for demonstrations or educational purposes.

Overall, this model serves as an innovative demonstration of electromagnetic principles and provides insights into the operation and control of electromechanical systems. The detailed circuit diagrams and accompanying photos facilitate a comprehensive understanding of the model's construction and functionality.Using the principles of a horizontal steam engine I constructed a model in which the steam cylinder is replaced by an electromagnet with a moving core. The construction details of the model are of little importance, as the photos give all the information you need.

The cylinder is replaced by an coil, while an iron core replaces the piston of a ste am engine. The construction details of both are shown in the photos below. If the core is placed about half of its length into the coil, and the current is then switched on, the core will be sucked right into the coil. The current will then be automatically switched off by the associated electronics. The core keeps on moving, due to the energy stored in the flywheel, until it comes out at the other end of the coil.

When the current is then switched on again the action repeats in the opposite direction. The core (piston) is pulled alternately backwards and forward thus forming a reciprocating engine. Two slotted opto switches are used to control the electromagnet and regulate its speed, placed as shown in the photos below. The slotted opto switches are mounted on the same printed circuit boards (PCBs) that I used in my Cliff Lift model.

The only difference is that one third of each has been cut off due to the proximity of the slotted opto switches to the gearwheel in this model. The first slotted opto switch switches the electromagnet current on and off using two shutters mounted on a gearwheel (Meccano part 95b) coupled to the flywheel.

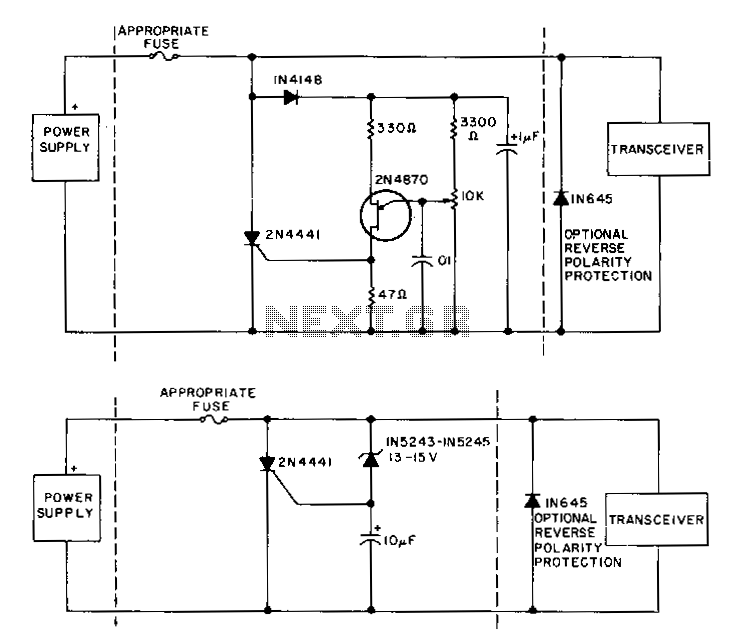

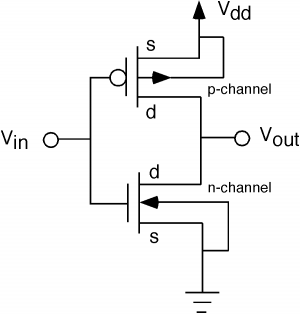

The second slotted opto switch measures the speed of the engine using the teeth of the same gearwheel. This speed information controls the current through the coil and acts as a regulator. Figure 2 shows the block diagram of the system, and figure 3 shows the full circuit diagram. The circuit diagram can also be downloaded separately from the link below. IC1 is a 555 timer and it is configured as an astable. Using the Reset input (pin 4), the Output (pin 3) is switched on and off under the command of the On/Off slotted opto switch sensor.

The square wave signal at the output of the 555 drives a power MOSFET transistor BUZ11. A second 555 timer, IC2, is configured as a monostable. It is triggered by the Speed slotted opto switch sensor and transistor T1. The output pulses are integrated to form a DC component used as control voltage for IC1 (input into pin 5). The control voltage has the effect of changing the frequency and the duty cycle of the square wave signal output from pin 3.

The current through the coil will therefore vary from 0. 5A to 4A and so the engine will run at a constant speed. The speed can be set using a potentiometer to change the monostable time period of IC2. 🔗 External reference

The model operates on the principles of electromagnetic induction, where the movement of the iron core within the coil generates a magnetic field that interacts with the current flowing through the coil. This interaction produces a force that drives the core in a reciprocating motion, akin to the operation of a steam engine but utilizing electrical energy instead of thermal energy.

The use of slotted opto switches provides precise control over the electromagnet's operation, allowing for real-time feedback and adjustment of the engine's speed. The integration of the 555 timers into the circuit provides a reliable means of generating the necessary control signals. The astable configuration of IC1 allows for continuous operation, while the monostable configuration of IC2 enables the detection of speed changes and the adjustment of the control voltage accordingly.

The circuit design emphasizes modularity and adaptability, as evidenced by the use of standard components such as the 555 timer and the power MOSFET, which are widely available and easy to integrate into various applications. The ability to adjust the speed via a potentiometer enhances the model's versatility, making it suitable for demonstrations or educational purposes.

Overall, this model serves as an innovative demonstration of electromagnetic principles and provides insights into the operation and control of electromechanical systems. The detailed circuit diagrams and accompanying photos facilitate a comprehensive understanding of the model's construction and functionality.Using the principles of a horizontal steam engine I constructed a model in which the steam cylinder is replaced by an electromagnet with a moving core. The construction details of the model are of little importance, as the photos give all the information you need.

The cylinder is replaced by an coil, while an iron core replaces the piston of a ste am engine. The construction details of both are shown in the photos below. If the core is placed about half of its length into the coil, and the current is then switched on, the core will be sucked right into the coil. The current will then be automatically switched off by the associated electronics. The core keeps on moving, due to the energy stored in the flywheel, until it comes out at the other end of the coil.

When the current is then switched on again the action repeats in the opposite direction. The core (piston) is pulled alternately backwards and forward thus forming a reciprocating engine. Two slotted opto switches are used to control the electromagnet and regulate its speed, placed as shown in the photos below. The slotted opto switches are mounted on the same printed circuit boards (PCBs) that I used in my Cliff Lift model.

The only difference is that one third of each has been cut off due to the proximity of the slotted opto switches to the gearwheel in this model. The first slotted opto switch switches the electromagnet current on and off using two shutters mounted on a gearwheel (Meccano part 95b) coupled to the flywheel.

The second slotted opto switch measures the speed of the engine using the teeth of the same gearwheel. This speed information controls the current through the coil and acts as a regulator. Figure 2 shows the block diagram of the system, and figure 3 shows the full circuit diagram. The circuit diagram can also be downloaded separately from the link below. IC1 is a 555 timer and it is configured as an astable. Using the Reset input (pin 4), the Output (pin 3) is switched on and off under the command of the On/Off slotted opto switch sensor.

The square wave signal at the output of the 555 drives a power MOSFET transistor BUZ11. A second 555 timer, IC2, is configured as a monostable. It is triggered by the Speed slotted opto switch sensor and transistor T1. The output pulses are integrated to form a DC component used as control voltage for IC1 (input into pin 5). The control voltage has the effect of changing the frequency and the duty cycle of the square wave signal output from pin 3.

The current through the coil will therefore vary from 0. 5A to 4A and so the engine will run at a constant speed. The speed can be set using a potentiometer to change the monostable time period of IC2. 🔗 External reference