Hot-air Rework Station

This hot-air rework station is suitable for professionals and hobbyists requiring precise temperature control and significant airflow. It features a digital display showing the actual air temperature, with a maximum flow rate of 23 liters per minute. This powerful device is versatile and can be utilized for various applications, including standard SMD reflow, repair, removal, thermal IC stress testing, thermoplastic welding, and shrink-wrapping.

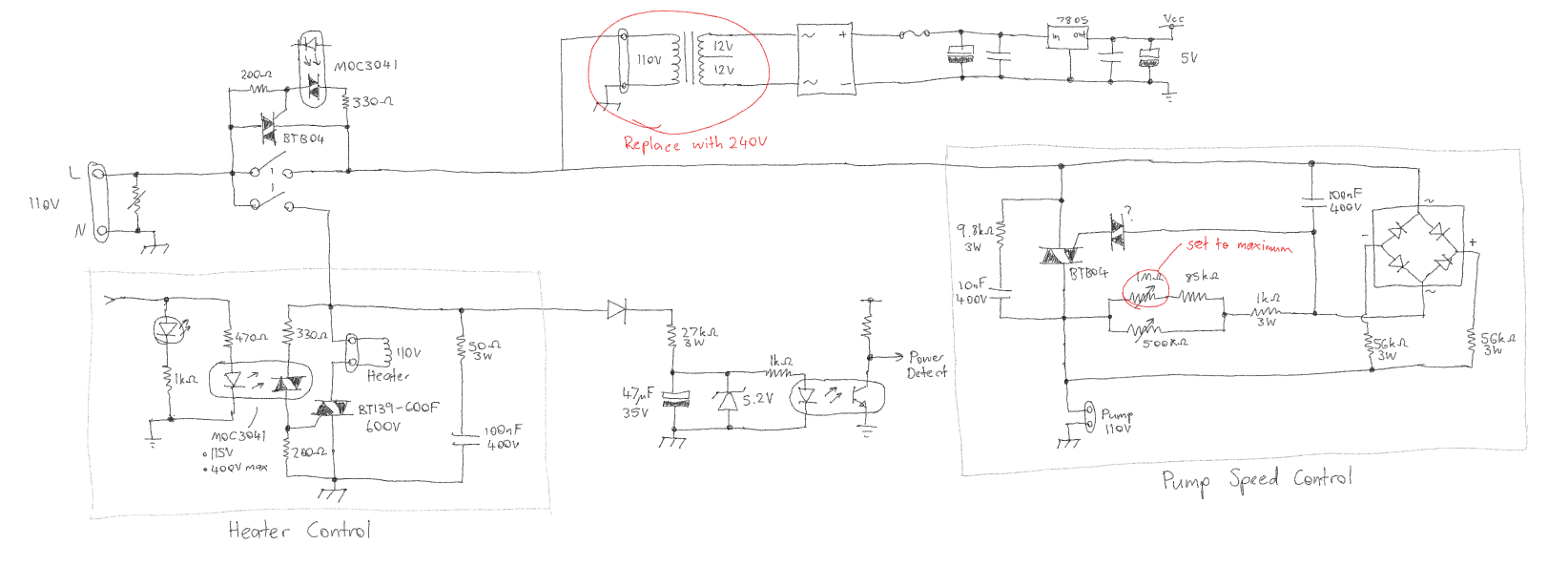

Features include closed-loop temperature control, rapid heating capabilities, an anti-static design, and an intelligent cooling system that maintains airflow after the unit is turned off until the air temperature drops below 100°C. The temperature adjustment range spans from 100°C to 480°C, with a handle length (including air line) of 120 cm. The noise level is below 40 dB, and it operates on a 110VAC input.

The hot-air rework station operates using a closed-loop temperature control system, which allows for precise adjustments to maintain the desired temperature during operation. This feature is critical for applications that require consistent thermal profiles to prevent damage to sensitive components. The rapid heating capability ensures that the station can reach operational temperatures quickly, thereby reducing downtime and improving workflow efficiency.

The anti-static design is essential for protecting electronic components from electrostatic discharge (ESD), which can cause irreparable damage to sensitive devices. This feature is particularly important in environments where static-sensitive components are handled frequently.

The intelligent cooling system enhances the safety and longevity of the tool by continuing to circulate air after the unit is powered off. This function helps to cool the heating element and surrounding components gradually, preventing thermal shock and extending the life of the device.

With a temperature adjustment range of 100°C to 480°C, this rework station can accommodate a wide variety of materials and applications, from delicate electronic components to more robust thermoplastic materials. The extended handle length of 120 cm provides flexibility and ease of use, allowing operators to maneuver comfortably around their workspace.

Operating at a noise level below 40 dB ensures that the device can be used in quiet environments without causing disturbances. The 110VAC input makes it compatible with standard electrical outlets, facilitating ease of setup and use in various locations. Overall, this hot-air rework station is a versatile and essential tool for any professional or hobbyist engaged in electronic assembly and repair work. This hot-air rework station is great for professionals and hobbyists in need of tight temperature tolerances and large air flows. This unit displays a digital readout of the actual air temperature with a flow rate of up to 23L per minute.

This very powerful unit can be used for multiple applications including standard SMD reflow/repair/removal, thermal IC stress testing, thermoplastic welding, and shrink-wrapping. Features: Closed-loop temperature control Heats up quickly Anti-static design Intelligent cooling system maintains airflow after the unit is powered off until the air temperature is below 100°C Temperature adjustment range: 100 ~ 480°C Handle length (including air line): 120cm Noise: <40dB 110VAC input 🔗 External reference

Features include closed-loop temperature control, rapid heating capabilities, an anti-static design, and an intelligent cooling system that maintains airflow after the unit is turned off until the air temperature drops below 100°C. The temperature adjustment range spans from 100°C to 480°C, with a handle length (including air line) of 120 cm. The noise level is below 40 dB, and it operates on a 110VAC input.

The hot-air rework station operates using a closed-loop temperature control system, which allows for precise adjustments to maintain the desired temperature during operation. This feature is critical for applications that require consistent thermal profiles to prevent damage to sensitive components. The rapid heating capability ensures that the station can reach operational temperatures quickly, thereby reducing downtime and improving workflow efficiency.

The anti-static design is essential for protecting electronic components from electrostatic discharge (ESD), which can cause irreparable damage to sensitive devices. This feature is particularly important in environments where static-sensitive components are handled frequently.

The intelligent cooling system enhances the safety and longevity of the tool by continuing to circulate air after the unit is powered off. This function helps to cool the heating element and surrounding components gradually, preventing thermal shock and extending the life of the device.

With a temperature adjustment range of 100°C to 480°C, this rework station can accommodate a wide variety of materials and applications, from delicate electronic components to more robust thermoplastic materials. The extended handle length of 120 cm provides flexibility and ease of use, allowing operators to maneuver comfortably around their workspace.

Operating at a noise level below 40 dB ensures that the device can be used in quiet environments without causing disturbances. The 110VAC input makes it compatible with standard electrical outlets, facilitating ease of setup and use in various locations. Overall, this hot-air rework station is a versatile and essential tool for any professional or hobbyist engaged in electronic assembly and repair work. This hot-air rework station is great for professionals and hobbyists in need of tight temperature tolerances and large air flows. This unit displays a digital readout of the actual air temperature with a flow rate of up to 23L per minute.

This very powerful unit can be used for multiple applications including standard SMD reflow/repair/removal, thermal IC stress testing, thermoplastic welding, and shrink-wrapping. Features: Closed-loop temperature control Heats up quickly Anti-static design Intelligent cooling system maintains airflow after the unit is powered off until the air temperature is below 100°C Temperature adjustment range: 100 ~ 480°C Handle length (including air line): 120cm Noise: <40dB 110VAC input 🔗 External reference