Hydraulic system

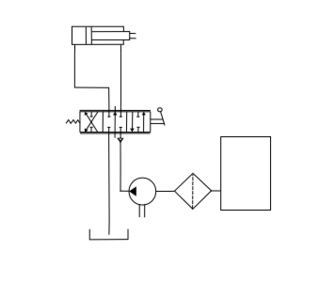

A hydraulic or hydrostatic drive system, also known as hydraulic power transmission, utilizes pressurized hydraulic fluid to drive machinery. The term hydrostatic refers to energy transfer through flow and pressure rather than the kinetic energy of the flow. This system essentially comprises three main components: the generator (such as a hydraulic pump driven by an electric motor, combustion engine, or windmill), valves, filters, and piping for system guidance and control; and the motor (like a hydraulic motor or hydraulic cylinder) that drives the machinery. Pascal's law underpins hydraulic drive systems, indicating that the pressure remains constant throughout the system, resulting in forces exerted by the fluid being equal to pressure multiplied by area. Consequently, a small piston experiences a minor force, while a large piston experiences a significant force. This principle applies to hydraulic pumps with small swept volumes requiring minimal torque, paired with hydraulic motors with larger swept volumes providing substantial torque. By throttling the fluid between the generator and motor components or utilizing hydraulic pumps and/or motors with adjustable swept volumes, the transmission ratio can be readily modified. Throttling can limit transmission efficiency, whereas adjustable pumps and motors can achieve high efficiency. Historically, hydraulic drive systems faced little competition from other adjustable electric drive systems until around 1980. Today, electric drive systems using servo motors offer excellent control and can effectively compete with rotating hydraulic drive systems. However, hydraulic cylinders remain unmatched for linear high forces, making them advantageous for applications requiring linear motion. Hydraulic cylinders, or linear hydraulic motors, are mechanical actuators that generate linear force through a linear stroke. They are among the most recognized hydraulic components, capable of exerting pushing and pulling forces of millions of metric tons using a straightforward hydraulic system. Basic hydraulic cylinders are often employed in presses, consisting of a volume encased in iron with a plunger that is sealed. When hydraulic fluid is pumped into this volume, the plunger is forced outward with a force determined by the plunger area multiplied by pressure. More advanced hydraulic cylinders feature a body with end covers, a piston rod with a piston, and a cylinder head. Typically, one end connects to a single clevis, while the piston rod is equipped with another clevis on the opposite end. The cylinder shell generally includes hydraulic connections on both ends, allowing oil to be pushed under the piston to extend the piston rod while returning oil from the space between the piston and cylinder head back to the oil tank. Simple hydraulic cylinders can operate at maximum pressures of approximately 70 bar, with subsequent levels at 140 bar, 210 bar, and 320/350 bar, often requiring custom builds for higher pressures. The stroke length of hydraulic cylinders is limited by manufacturing processes, with most cylinders having strokes between 0.3 and 5 meters, although lengths of 12-15 meters are available from a limited number of suppliers. In instances where the retracted length of the cylinder exceeds structural requirements, telescopic cylinders may be utilized.

The hydraulic drive system operates on the principle of Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows for the efficient transfer of force, making hydraulic systems particularly effective in applications requiring significant mechanical advantage. The generator component, typically a hydraulic pump, is critical for creating the necessary pressure within the system. It can be driven by various power sources, including electric motors, combustion engines, or renewable sources such as windmills, allowing for versatility in design and application.

The control of the hydraulic fluid flow is managed through a series of valves and filters, which ensure that the system operates smoothly and efficiently. These components are essential for directing the flow of hydraulic fluid to the motor or hydraulic cylinder, allowing for precise control over the machinery's operation. The motor, which can be a hydraulic motor or a hydraulic cylinder, converts the hydraulic energy back into mechanical energy, enabling the machinery to perform its intended function.

Hydraulic cylinders are particularly noteworthy for their ability to generate high linear forces with relatively simple designs. They are utilized in a variety of applications, from industrial presses to construction equipment, where high force output is required. The design of hydraulic cylinders can vary significantly, with options for single-acting or double-acting configurations, depending on the specific application requirements. The ability to customize hydraulic cylinders for specific pressure ratings and stroke lengths further enhances their utility in diverse engineering applications.

In summary, hydraulic drive systems provide a robust solution for transmitting power in various mechanical applications, leveraging the principles of fluid dynamics and pressure to achieve high efficiency and force output. The continued development of hydraulic technology, alongside advancements in electric drive systems, ensures that hydraulic solutions remain relevant and competitive in modern engineering contexts.A hydraulic or hydrostatic drive system or hydraulic power transmission is a drive or transmission system that uses hydraulic fluid under pressureto drive machinery. The term hydrostatic refers to the transfer of energy from flow and pressure, not from the kinetic energy of the flow.

Such a system basically consists of three parts. The generator (e. g. a hydraulic pump, driven by an electric motor, a combustion engine or a windmill ); valves, filters, piping etc. (to guide and control the system); the motor (e. g. a hydraulic motor or hydraulic cylinder ) to drive the machinery. Pascal`s law is the basis of hydraulic drive systems. As the pressure in the system is the same, the force that the fluid gives to the surroundings is therefore equal to pressure x area.

In such a way, a small piston feels a small force and a large piston feels a large force. The same counts for a hydraulic pump with a small swept volume, that asks for a small torque, combined with a hydraulic motor with a large sweptvolume, that gives a large torque. By throttling the fluid between generator part and motor part, or by using hydraulic pumps and/or motors with adjustable swept volume, the ratio of the transmission can be changed easily.

In case throttling is used, the efficiency of the transmission is limited; in case adjustable pumps and motors are used, the efficiency however is very large. In fact, up to around 1980, a hydraulic drive system had hardly any competition from other adjustable (electric) drive systems.

Nowadays electric drive systems using electric servo-motors can be controlled in an excellent way and can easily compete with rotating hydraulic drive systems. Hydraulic cylinders are in fact without competition for linear (high) forces. For these cylinders anyway hydraulic systems will remain of interest and if such a system is available, it is easy and logical to use this system also for the rotating drives of the cooling systems.

Hydraulic cylinders (also called linear hydraulic motors) are mechanical actuators that are used to give a linear force through a linear stroke. A hydraulic cylinder is without doubt the best known hydraulic component. Hydraulic cylinders are able to give pushing and pulling forces of millions of metric tons, with only a simple hydraulic system.

Very simple hydraulic cylinders are used in presses; here the cylinder consists out of a volume in a piece of iron with a plunger pushed in it and sealed with a cover. By pumping hydraulic fluid in the volume, the plunger is pushed out with a force of plunger-area * pressure.

More sophisticated cylinders have a body with end cover, a piston-rod with piston and a cylinder-head. At one side the bottom is for instance connected to a single clevis, whereas at the other side, the piston rod also is foreseen with a single clevis.

The cylinder shell normally has hydraulic connections at both sides. A connection at bottom side and one at cylinder head side. If oil is pushed under the piston, the piston-rod is pushed out and oil that was between the piston and the cylinder head is pushed back to the oil-tank again. Simple hydraulic cylinders have a maximum working pressure of about 70 bar, the next step is 140 bar, 210 bar, 320/350 bar and further, the cylinders are in general custom build.

The stroke of a hydraulic cylinder is limited by the manufacturing process. The majority of hydraulic cylinders have a stroke between 0, 3 and 5 metres, whereas 12-15 metre stroke is also possible, but for this length only a limited number of suppliers are on the market. In case the retracted length of the cylinder is too long for the cylinder to be build in the structure.

In this case telescopic cylinders can be used. One has to r 🔗 External reference

The hydraulic drive system operates on the principle of Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows for the efficient transfer of force, making hydraulic systems particularly effective in applications requiring significant mechanical advantage. The generator component, typically a hydraulic pump, is critical for creating the necessary pressure within the system. It can be driven by various power sources, including electric motors, combustion engines, or renewable sources such as windmills, allowing for versatility in design and application.

The control of the hydraulic fluid flow is managed through a series of valves and filters, which ensure that the system operates smoothly and efficiently. These components are essential for directing the flow of hydraulic fluid to the motor or hydraulic cylinder, allowing for precise control over the machinery's operation. The motor, which can be a hydraulic motor or a hydraulic cylinder, converts the hydraulic energy back into mechanical energy, enabling the machinery to perform its intended function.

Hydraulic cylinders are particularly noteworthy for their ability to generate high linear forces with relatively simple designs. They are utilized in a variety of applications, from industrial presses to construction equipment, where high force output is required. The design of hydraulic cylinders can vary significantly, with options for single-acting or double-acting configurations, depending on the specific application requirements. The ability to customize hydraulic cylinders for specific pressure ratings and stroke lengths further enhances their utility in diverse engineering applications.

In summary, hydraulic drive systems provide a robust solution for transmitting power in various mechanical applications, leveraging the principles of fluid dynamics and pressure to achieve high efficiency and force output. The continued development of hydraulic technology, alongside advancements in electric drive systems, ensures that hydraulic solutions remain relevant and competitive in modern engineering contexts.A hydraulic or hydrostatic drive system or hydraulic power transmission is a drive or transmission system that uses hydraulic fluid under pressureto drive machinery. The term hydrostatic refers to the transfer of energy from flow and pressure, not from the kinetic energy of the flow.

Such a system basically consists of three parts. The generator (e. g. a hydraulic pump, driven by an electric motor, a combustion engine or a windmill ); valves, filters, piping etc. (to guide and control the system); the motor (e. g. a hydraulic motor or hydraulic cylinder ) to drive the machinery. Pascal`s law is the basis of hydraulic drive systems. As the pressure in the system is the same, the force that the fluid gives to the surroundings is therefore equal to pressure x area.

In such a way, a small piston feels a small force and a large piston feels a large force. The same counts for a hydraulic pump with a small swept volume, that asks for a small torque, combined with a hydraulic motor with a large sweptvolume, that gives a large torque. By throttling the fluid between generator part and motor part, or by using hydraulic pumps and/or motors with adjustable swept volume, the ratio of the transmission can be changed easily.

In case throttling is used, the efficiency of the transmission is limited; in case adjustable pumps and motors are used, the efficiency however is very large. In fact, up to around 1980, a hydraulic drive system had hardly any competition from other adjustable (electric) drive systems.

Nowadays electric drive systems using electric servo-motors can be controlled in an excellent way and can easily compete with rotating hydraulic drive systems. Hydraulic cylinders are in fact without competition for linear (high) forces. For these cylinders anyway hydraulic systems will remain of interest and if such a system is available, it is easy and logical to use this system also for the rotating drives of the cooling systems.

Hydraulic cylinders (also called linear hydraulic motors) are mechanical actuators that are used to give a linear force through a linear stroke. A hydraulic cylinder is without doubt the best known hydraulic component. Hydraulic cylinders are able to give pushing and pulling forces of millions of metric tons, with only a simple hydraulic system.

Very simple hydraulic cylinders are used in presses; here the cylinder consists out of a volume in a piece of iron with a plunger pushed in it and sealed with a cover. By pumping hydraulic fluid in the volume, the plunger is pushed out with a force of plunger-area * pressure.

More sophisticated cylinders have a body with end cover, a piston-rod with piston and a cylinder-head. At one side the bottom is for instance connected to a single clevis, whereas at the other side, the piston rod also is foreseen with a single clevis.

The cylinder shell normally has hydraulic connections at both sides. A connection at bottom side and one at cylinder head side. If oil is pushed under the piston, the piston-rod is pushed out and oil that was between the piston and the cylinder head is pushed back to the oil-tank again. Simple hydraulic cylinders have a maximum working pressure of about 70 bar, the next step is 140 bar, 210 bar, 320/350 bar and further, the cylinders are in general custom build.

The stroke of a hydraulic cylinder is limited by the manufacturing process. The majority of hydraulic cylinders have a stroke between 0, 3 and 5 metres, whereas 12-15 metre stroke is also possible, but for this length only a limited number of suppliers are on the market. In case the retracted length of the cylinder is too long for the cylinder to be build in the structure.

In this case telescopic cylinders can be used. One has to r 🔗 External reference