laser controller circuit

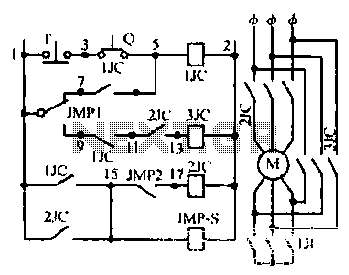

The development of the entire system necessitated a thorough identification of all processes related to the laser controller. The initial diagram outlines the primary physical components utilized in the CNC laser system. The setup includes a power supply, a DB-25 connector for reporting various laser states, solenoid-controlled gas lines, water flow and cooling systems, a servo-driven CNC table, and a computer system serving as the central control unit. The servos are powered by Gecko drives, which are managed by Jon Elson's Universal Stepper Controller (USC). Approximately 50 I/O lines connect to the control unit, prompting the creation of a block diagram detailing the internal electronic components. This diagram, while it does not include elements such as indicator lights, power switches, and the power supply, serves as a solid foundation. The blocks labeled JAM buzzer and PWM module were ultimately integrated into a custom circuit for the project. Digi-Key part numbers for most connectors were included in the drawing to facilitate informed ordering. Parts were ordered in several phases, and although a final Bill of Materials (BOM) would be ideal, it remains unavailable. The Gecko drives and USC board are well-regarded, but the laser controller also incorporates custom electronics that monitor the laser states, generate a pulse-width modulated signal, and communicate an emergency stop (E-stop) to the Universal Stepper Controller. The schematic for these custom electronics was created using Eagle schematic software, and the Eagle-formatted schematic is available for download. The laser measurement circuitry was based on specifications provided by the laser manufacturer. These circuits utilize differential line receivers and drivers. The laser states are fed into a "Just A Minute" (JAM) circuit, originally designed for a game show scenario, where multiple contestants activate a switch. When the switch is engaged, an indicator light activates, locking out other contestants. This design is ideal for the application, as it allows for the registration of which system state goes low, locks out other inputs, and activates the E-stop toggle on the USC board. The custom board also features a PWM circuit based on a 4541 programmable timer that interfaces with a binary counter and magnitude comparator. Additionally, there is a section dedicated to debouncing a push button, which toggles a D-type flip-flop. This circuit receives power from an unswitched power supply; pressing the push button activates a solid-state relay that powers the remaining circuitry. The schematic illustrates the I/O challenge presented by the laser controller, with over 120 lines from connectors leading to limit switches, encoders, Gecko drives, and the USC board. All lines are directed into one of four 30-pin female headers, which simplifies connections by minimizing soldering and allowing for wire wrap connections between header pins. This approach offers several advantages: it reduces the amount of soldering required, facilitates disconnection, and allows the "logic" of line connections to be managed via software, thus preventing the need for mechanical oversight of the header block connections. Overall, this method centralizes the complexity of the circuit into four main headers.

The CNC laser system's design emphasizes modularity and ease of maintenance. The integration of a power supply, solenoid-controlled gas lines, and cooling systems ensures efficient operation while maintaining safety protocols. The use of Gecko drives and the USC enhances the precision of the servo-driven table, allowing for intricate movements necessary for laser cutting and engraving applications. The inclusion of the JAM circuit serves a critical function in monitoring the operational states of the laser, ensuring that any drop in system performance is immediately addressed, thereby enhancing the safety and reliability of the operation.

The schematic, structured with the Eagle software, provides a clear representation of the interconnections among the various components, facilitating troubleshooting and future upgrades. The decision to use female headers for connections not only simplifies assembly but also allows for quick modifications without the need for extensive soldering. This design philosophy reflects a modern approach to electronic circuit design, prioritizing flexibility and user-friendliness. The PWM circuit's implementation ensures that the laser operates within optimal parameters, adjusting the output based on real-time feedback from the system.

Overall, the detailed planning and execution of this CNC laser controller project illustrate the complexities involved in modern electronic design, where multiple systems must work cohesively to achieve a common goal. The thoughtful integration of components and the strategic use of software to manage connections highlight the importance of a well-structured approach in electronic engineering.Development of the whole system required an exhaustive identification of all processes of the laser controller. I started with this diagram which outlines the major physical components that will be used for the cnc laser.

The laser has a power supply, a db-25 connector which reports various states of the laser, gas lines which are controlled by so lenoids, water flow and cooling systems, a servo driven CNC table, and a computer system for the central controlling unit. The servos are driven by Gecko drives, the Geckos are controlled by Jon Elson`s Universal Stepper Controller (USC).

There are an intimidating 50 or so I/O lines going into the control unit, so it was time to make another block diagram of all the internal electronic components. This picture was generated, which still leaves out items like indicator lights, power switches as well as the power supply that eventually was added to the circuit, but it was a good start.

The blocks marked JAM buzzer and PWM module were eventually combined into the custom circuit that was part of the project. Digi-key part numbers of most of the connectors were included in the drawing to help with intelligent ordering.

Ordering parts occurred over several iterations and while it`d be nice to put together a final BOM, one does not exist. The Gecko drives and the USC board are nice, but the laser controller also has some custom electronics that measure the states of laser itself, generate a pulse width modulated signal, and report an E-stop to the Unversal Stepper Controller.

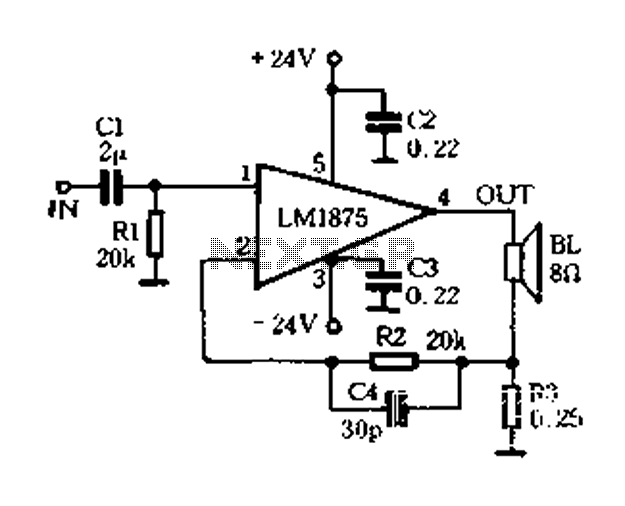

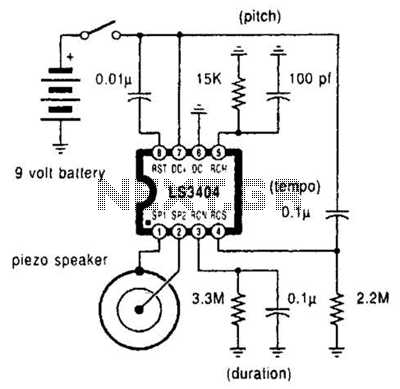

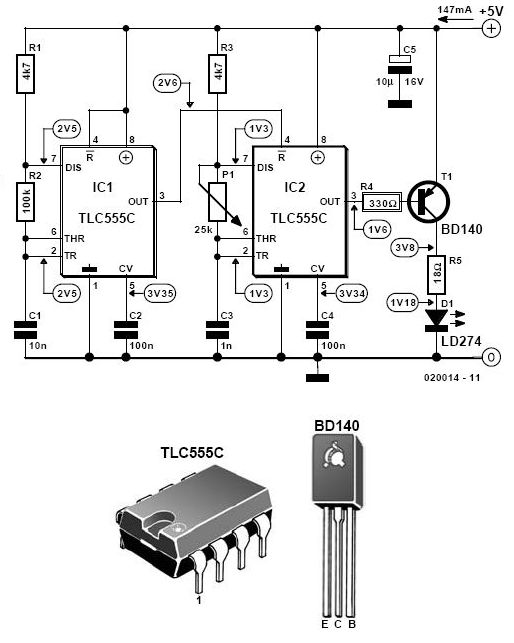

The schematic of the custom electronics was generated using Eagle schematic software. The Eagle-formatted schematic can be downloaded here. You can try loading this big picture as well. The laser measurement was based on circuitry specified by the laser manufacturer (see figures 4-2 and 4-4). These circuits use differential line recievers and drivers. The states of the laser were fed into a "Just A Minute" or JAM circuit ( original schematic ). The JAM circuit was originally designed for a game show situation, where multiple contestants can hit a switch, when the switch is thrown a light goes on indicating who hit the button, and the rest of the contestants are locked out.

Perfect for my application, because if any of multiple states go low I want to register which system went low, lock out other inputs, and then flip the E-stop toggle of the USC board. The custom board also has a PWM circuit which is based on a 4541 programmable timer that feed into a binary counter and magnitude comparator combination.

There`s also a section on the circuit that debounces the push of a button and then toggles a D-type flip flop. This receives power from an unswitched power supply, when the user hits the pushbutton it turns on a solid state relay that powers up the remaining circuit.

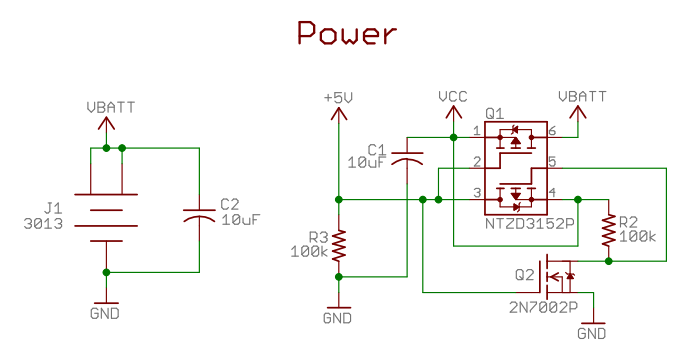

The schematic epitomizes the I/O problem posed by the laser controller. There are over 120 different lines from connectors going to limit switches, encoders, geckos and the USC board. All lines were led into one of four 30 pin female headers. This was good way to go because it reduced any soldering or other types of direct connections between components - basically all connections between components were handled by linking between header pins using wire wrap.

This has several advantages: 1) it is an overall reduction in soldering - soldering is fine but its harder to disconnect - connections are made by crimping wires onto pins and then inserted into the header 2) The "logic" of how lines are linked is managed in software as described in the next section - this avoids mechanically looking at a header block from the geckos and deciding which wires have to be soldered to the pins leading to the encoders. 3) Overall, it reduces the spagetti of the circuit. Dont get me wrong, the spagetti is still there, but its centralized into four main headers. Readers may not want to go with this strategy, but 🔗 External reference

The CNC laser system's design emphasizes modularity and ease of maintenance. The integration of a power supply, solenoid-controlled gas lines, and cooling systems ensures efficient operation while maintaining safety protocols. The use of Gecko drives and the USC enhances the precision of the servo-driven table, allowing for intricate movements necessary for laser cutting and engraving applications. The inclusion of the JAM circuit serves a critical function in monitoring the operational states of the laser, ensuring that any drop in system performance is immediately addressed, thereby enhancing the safety and reliability of the operation.

The schematic, structured with the Eagle software, provides a clear representation of the interconnections among the various components, facilitating troubleshooting and future upgrades. The decision to use female headers for connections not only simplifies assembly but also allows for quick modifications without the need for extensive soldering. This design philosophy reflects a modern approach to electronic circuit design, prioritizing flexibility and user-friendliness. The PWM circuit's implementation ensures that the laser operates within optimal parameters, adjusting the output based on real-time feedback from the system.

Overall, the detailed planning and execution of this CNC laser controller project illustrate the complexities involved in modern electronic design, where multiple systems must work cohesively to achieve a common goal. The thoughtful integration of components and the strategic use of software to manage connections highlight the importance of a well-structured approach in electronic engineering.Development of the whole system required an exhaustive identification of all processes of the laser controller. I started with this diagram which outlines the major physical components that will be used for the cnc laser.

The laser has a power supply, a db-25 connector which reports various states of the laser, gas lines which are controlled by so lenoids, water flow and cooling systems, a servo driven CNC table, and a computer system for the central controlling unit. The servos are driven by Gecko drives, the Geckos are controlled by Jon Elson`s Universal Stepper Controller (USC).

There are an intimidating 50 or so I/O lines going into the control unit, so it was time to make another block diagram of all the internal electronic components. This picture was generated, which still leaves out items like indicator lights, power switches as well as the power supply that eventually was added to the circuit, but it was a good start.

The blocks marked JAM buzzer and PWM module were eventually combined into the custom circuit that was part of the project. Digi-key part numbers of most of the connectors were included in the drawing to help with intelligent ordering.

Ordering parts occurred over several iterations and while it`d be nice to put together a final BOM, one does not exist. The Gecko drives and the USC board are nice, but the laser controller also has some custom electronics that measure the states of laser itself, generate a pulse width modulated signal, and report an E-stop to the Unversal Stepper Controller.

The schematic of the custom electronics was generated using Eagle schematic software. The Eagle-formatted schematic can be downloaded here. You can try loading this big picture as well. The laser measurement was based on circuitry specified by the laser manufacturer (see figures 4-2 and 4-4). These circuits use differential line recievers and drivers. The states of the laser were fed into a "Just A Minute" or JAM circuit ( original schematic ). The JAM circuit was originally designed for a game show situation, where multiple contestants can hit a switch, when the switch is thrown a light goes on indicating who hit the button, and the rest of the contestants are locked out.

Perfect for my application, because if any of multiple states go low I want to register which system went low, lock out other inputs, and then flip the E-stop toggle of the USC board. The custom board also has a PWM circuit which is based on a 4541 programmable timer that feed into a binary counter and magnitude comparator combination.

There`s also a section on the circuit that debounces the push of a button and then toggles a D-type flip flop. This receives power from an unswitched power supply, when the user hits the pushbutton it turns on a solid state relay that powers up the remaining circuit.

The schematic epitomizes the I/O problem posed by the laser controller. There are over 120 different lines from connectors going to limit switches, encoders, geckos and the USC board. All lines were led into one of four 30 pin female headers. This was good way to go because it reduced any soldering or other types of direct connections between components - basically all connections between components were handled by linking between header pins using wire wrap.

This has several advantages: 1) it is an overall reduction in soldering - soldering is fine but its harder to disconnect - connections are made by crimping wires onto pins and then inserted into the header 2) The "logic" of how lines are linked is managed in software as described in the next section - this avoids mechanically looking at a header block from the geckos and deciding which wires have to be soldered to the pins leading to the encoders. 3) Overall, it reduces the spagetti of the circuit. Dont get me wrong, the spagetti is still there, but its centralized into four main headers. Readers may not want to go with this strategy, but 🔗 External reference