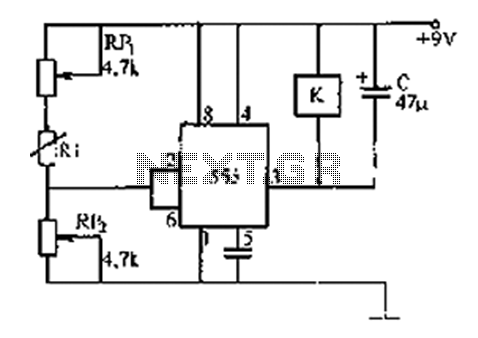

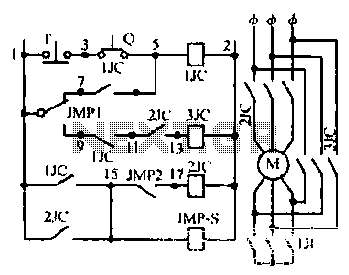

Motor Y starting circuit shape

Motor windings are set to connect in a Y configuration while the load is active. The system includes an electric suction mechanism, and the motor is designed to operate under specific conditions. It is rated for 600 revolutions per minute and is equipped with features to monitor and manage power loss and overload situations. The electrostatic suction units are connected to the windings to enhance performance while preventing pressure-related issues. The system incorporates protective measures to ensure the motor does not become overloaded or suffer from voltage drops, which can occur under unexpected circumstances. In the event of power loss, the motor will shut down to prevent damage, and recovery protocols are in place to restart the system once conditions are safe.

The motor control circuit is designed to facilitate the operation of the motor under specified conditions while ensuring safety and efficiency. The Y configuration of the windings allows for effective phase distribution, which is crucial for smooth motor operation. The electric suction system enhances the motor's performance by providing necessary airflow for cooling and efficiency.

The circuit includes several components for monitoring and control, such as voltage sensors that detect drops below a predetermined threshold. If the voltage drops significantly, the circuit will automatically disconnect the power supply to the motor, preventing potential damage due to overload or overheating. The use of electrostatic suction units is also critical, as they help maintain optimal conditions within the motor environment, reducing the risk of pressure-related failures.

In addition, the system features a recovery mechanism that allows the motor to restart safely once the conditions return to normal. This involves a sequence of checks to ensure that the power supply is stable and that the motor is not at risk of immediate overload upon reactivation. The design emphasizes reliability and safety, making it suitable for various applications where motor performance is critical, and operational conditions may fluctuate. Overall, this motor control circuit integrates advanced features to enhance functionality while prioritizing protection against adverse operating conditions.Motor windings are scheduled to join Y Rong, while L IS ON, 2JC {}} electric suction, Union minister motor Y} i pick Save iIf /) f ~ tjj. ON 115 causes JMP - S also coat LU r + ashamed, to turn the motor was built gun delete, turn a motor built escape Wu j l rated

revolution built 600 / O, SO% (available by occasion eyes bare setting). JMPI friends ha. 1-7 disconnected. IJC loss of power release, YJ Zhi disconnect coupling 1-9 pick contempt. 9 - II 133 is also turned on. 3JC electrostatic suction units, electric day l set r winding connected into expansion, with eight to avoid pressure JE derivatives operation. Y - A move south W. H flail r Cheng Bi. DA. IMP S f remains energized as when i perform what-machine running water smell off monitoring. When the motor due to external Harada such overload. Xu off the supply voltage drops too unexpected situations such as hair E, paraphrased f drop IO - 20Q / o.

iMP2 off, 2JC, 3JC has lost power released, the motor power supply is cut off. Protects the motor will not be trapped overload, Feng H, power supply voltage is low and spread bad. Meanwhile JMP - S Esen electricity. JMPI. IMP2 pecking recovery team has prepared state government to start again.

The motor control circuit is designed to facilitate the operation of the motor under specified conditions while ensuring safety and efficiency. The Y configuration of the windings allows for effective phase distribution, which is crucial for smooth motor operation. The electric suction system enhances the motor's performance by providing necessary airflow for cooling and efficiency.

The circuit includes several components for monitoring and control, such as voltage sensors that detect drops below a predetermined threshold. If the voltage drops significantly, the circuit will automatically disconnect the power supply to the motor, preventing potential damage due to overload or overheating. The use of electrostatic suction units is also critical, as they help maintain optimal conditions within the motor environment, reducing the risk of pressure-related failures.

In addition, the system features a recovery mechanism that allows the motor to restart safely once the conditions return to normal. This involves a sequence of checks to ensure that the power supply is stable and that the motor is not at risk of immediate overload upon reactivation. The design emphasizes reliability and safety, making it suitable for various applications where motor performance is critical, and operational conditions may fluctuate. Overall, this motor control circuit integrates advanced features to enhance functionality while prioritizing protection against adverse operating conditions.Motor windings are scheduled to join Y Rong, while L IS ON, 2JC {}} electric suction, Union minister motor Y} i pick Save iIf /) f ~ tjj. ON 115 causes JMP - S also coat LU r + ashamed, to turn the motor was built gun delete, turn a motor built escape Wu j l rated

revolution built 600 / O, SO% (available by occasion eyes bare setting). JMPI friends ha. 1-7 disconnected. IJC loss of power release, YJ Zhi disconnect coupling 1-9 pick contempt. 9 - II 133 is also turned on. 3JC electrostatic suction units, electric day l set r winding connected into expansion, with eight to avoid pressure JE derivatives operation. Y - A move south W. H flail r Cheng Bi. DA. IMP S f remains energized as when i perform what-machine running water smell off monitoring. When the motor due to external Harada such overload. Xu off the supply voltage drops too unexpected situations such as hair E, paraphrased f drop IO - 20Q / o.

iMP2 off, 2JC, 3JC has lost power released, the motor power supply is cut off. Protects the motor will not be trapped overload, Feng H, power supply voltage is low and spread bad. Meanwhile JMP - S Esen electricity. JMPI. IMP2 pecking recovery team has prepared state government to start again.