Lego Rotation Sensor Internals

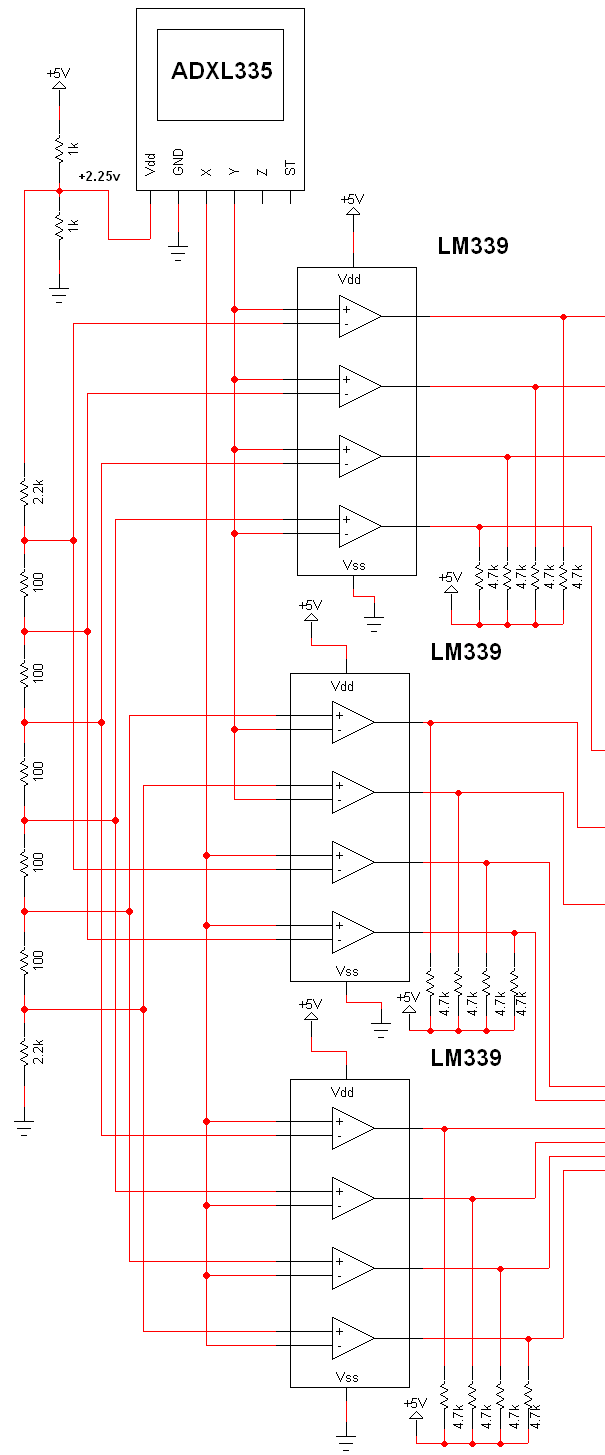

The Lego rotation sensor is a compact device that allows the RCX to measure the rotation of an axle with a resolution of 16 steps per turn. However, it experiences issues at low rotation speeds, where the read values can fluctuate randomly by one or two units. The sensor operates by communicating with the RCX using a two-phase scheme: during 2.9 ms, the RCX powers the sensor at +8V, followed by a 100 µs period where the RCX reads the analog value returned by the sensor. During the reading phase, the sensor relies on its internal capacitor for power. A detailed examination of the read phase reveals multiple traces accumulated over time while rotating the axle. The sensor communicates with the RCX using a four-level code, with voltage levels that may appear low compared to other measurements, potentially due to battery depletion. The read phase duration exhibits jitter, ranging from 90 µs to 125 µs. As the axle rotates clockwise, the output cycles through steps 1, 2, 3, 4, and back to 1. Conversely, when rotated counterclockwise, the sequence is 1, 4, 3, 2, and back to 1, which allows the RCX to determine the rotation direction. A noted issue arises during transitions between specific steps, where the output crosses certain voltage levels, posing a risk of misreading during sampling. The sampling occurs approximately 60 µs after the read phase begins. The transition time across voltage levels can be evaluated to around 1 µs, with sampling occurring every 3 ms, leading to a misread probability of about 1 in 3000. Alternative RCX programming languages, such as legOS and leJOS, mitigate this issue by performing consecutive readings, albeit at the cost of halving the maximum rotation speed. Observations indicate that slight manual adjustments during transitions can cause the readings to fluctuate. Further investigation into the sensor's internal components revealed that accessing the internals was challenging due to glued or heat-soldered parts. The circuit includes diodes D1 and D2 for rectifying the power supply, capacitor C1 for filtering, and opto-forks K1 and K2, which consist of an infrared LED and a phototransistor. The propeller-shaped blades interrupt the infrared beams, providing the four phases of the returned value, resulting in 16 steps per rotation. The IR LEDs are powered through resistor R1, supplying approximately 5 mA.

The Lego rotation sensor employs a sophisticated design that enables precise measurement of rotational movement. The sensor's operation hinges on a dual-phase communication system with the RCX, allowing it to switch between power and read modes efficiently. The reliance on capacitors to store energy during the power phase is critical, as it ensures that the sensor can function independently during the read phase. The four-level code used for communication is essential for differentiating the sensor's output states, which correspond to the position of the axle.

The transition issues observed during low-speed rotations highlight the importance of timing in the sensor's operation. The jitter in the read phase duration can lead to inconsistencies in the output, particularly during critical transitions. This behavior necessitates careful consideration during programming, especially when using alternative software that implements double sampling to reduce the likelihood of misreads.

The internal architecture of the sensor, featuring diodes for power rectification and capacitors for filtering, underscores the sensor's design complexity. The use of opto-forks for detecting rotational movement through infrared interruption is a clever application of optical sensing technology, allowing for high-resolution measurements. The propeller-shaped blades effectively increase the number of detectable steps per rotation, enhancing the sensor's performance.

Overall, the Lego rotation sensor exemplifies the integration of electronic components and software algorithms to achieve precise rotational measurements, though it also illustrates the challenges associated with low-speed operation and the need for robust error mitigation strategies.Lego rotation sensor is a nice little device that enables RCX to measure rotation of an axle with good resolution: 16 steps per turn. Unfortunately it is plagued with a problem: at low rotation speed value read seems to jump randomly from 1 or two units.

So I decided to have a fairly indiscrete look at it. here is what I discovered. Active sensors (rotation sensor, light sensor) communicate with RCX through a two phases scheme: during 2. 9ms, RCX powers sensor (+8V), then during about 100 µs RCX reads analog value returned by sensor. During read phase, no power is provided to sensor, and this one has to live on its own reserve. This is done by storing energy in a capacitor during power phase. Here is a zoom on read phas of a rotation sensor. Numerous traces are accumulated over some time while rotating axle of sensor. You can see that sensor communicates with RCX through a 4 levels code. The voltages I measured for this levels are: These values seem a bit low when compared to Michael Gasperi`s (see his rotation sensor page ), perhaps my batteries were exhausted. You can also see that there is some jitter in read phase duration (between 90 µs and 125 µs) As the axle is rotated clockwise, output cycles througs steps 1 > 2 > 3 > 4 > 1, and through steps 1 > 4 > 3 > 2 > 1 when rotated ccw.

This enables RCX to determinate rotation direction. As pointed out by here by JG rgen Stuber, we have here the first problem of rotation sensor: during transition between step 3 and 4, output crosses voltage of level 2, and between step 1 and 2, output crosses voltage of level 4. Since this transition takes some time, there is a probability that it happens just when RCX samples value.

I tried to determine sampling time, it seems to take place about 60 µs after beginning of read phase. Here is such a transitionbetween step 3 and step 4. We can see that transition time across 3. 3V (step 2) can be evaluated to 1 µs. Sampling is done every 3 ms, probability of misread can be evaluated to about 1/3000 at most. Some alternative RCX programming languages (legOS and leJOS) perform two consecutive readings and almost eliminate this problem at the cost of halving maximum rotation speed.

To obtain this trace, I simply rotated sensor by hand very slowly till I reached transition between steps. And instead of having a sudden jump between two values, I got a stable oscilloscope trace (hand shaking apart) showing a transition each 3ms!

And moving VERY little my hand I could modify the position of this transition, and especially place it just at sampling point - and counter began to jump between values. It seems that very close to transition position, there is synchronisation with power/read cycle, and this increases the previous problem: there is a lot of transitions instead of only one - and when rotating very slowly this transition is doomed to occur at sampling point and cause misread.

Note that even double sampling as performed by legOS and leJOS has no guarantee to give correct answer: if rotation is very slow two successive reads will happen during transition. To go further, I needed to look inside the sensor. Prying it open proved painful. I first cut the blue tabs below the baseplate, but sensor didn`t open. It seems that some tabs are glued or heat soldered, so I had to resort to brute force methods and cut everywhere between dark grey and blue parts.

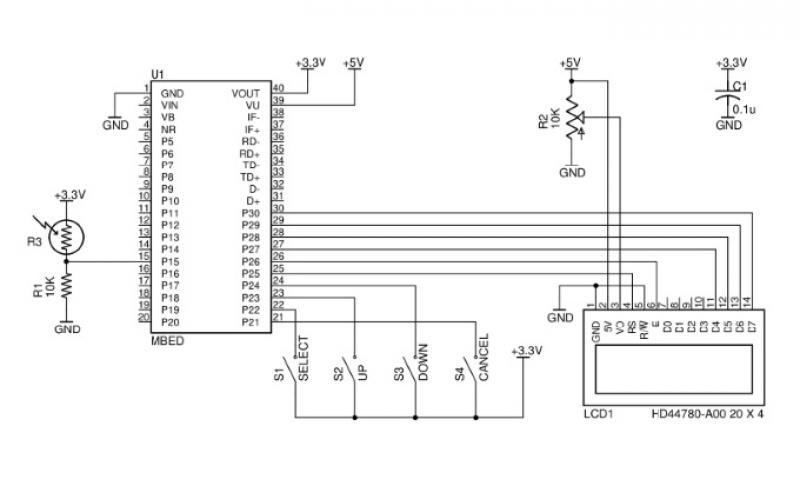

Moreover the wire is locked tight in upper part by a peg belonging to grey plate, and I had to cut that peg too. D1, D2 rectify power supply, C1 filters it. K1 and K2 are two opto-forks (marked S89, I didn`t found exact part type), one side contains an infra-red led, the other side a phototransistor.

Blade of propellar shape part can interrupt infrared beam of K1, K2, both or none, providing the four phases of the returned value. Since there are 4 blades, we obtain 16 steps per turn. IR leds receive power through R1 (about 5mA). The node be 🔗 External reference

The Lego rotation sensor employs a sophisticated design that enables precise measurement of rotational movement. The sensor's operation hinges on a dual-phase communication system with the RCX, allowing it to switch between power and read modes efficiently. The reliance on capacitors to store energy during the power phase is critical, as it ensures that the sensor can function independently during the read phase. The four-level code used for communication is essential for differentiating the sensor's output states, which correspond to the position of the axle.

The transition issues observed during low-speed rotations highlight the importance of timing in the sensor's operation. The jitter in the read phase duration can lead to inconsistencies in the output, particularly during critical transitions. This behavior necessitates careful consideration during programming, especially when using alternative software that implements double sampling to reduce the likelihood of misreads.

The internal architecture of the sensor, featuring diodes for power rectification and capacitors for filtering, underscores the sensor's design complexity. The use of opto-forks for detecting rotational movement through infrared interruption is a clever application of optical sensing technology, allowing for high-resolution measurements. The propeller-shaped blades effectively increase the number of detectable steps per rotation, enhancing the sensor's performance.

Overall, the Lego rotation sensor exemplifies the integration of electronic components and software algorithms to achieve precise rotational measurements, though it also illustrates the challenges associated with low-speed operation and the need for robust error mitigation strategies.Lego rotation sensor is a nice little device that enables RCX to measure rotation of an axle with good resolution: 16 steps per turn. Unfortunately it is plagued with a problem: at low rotation speed value read seems to jump randomly from 1 or two units.

So I decided to have a fairly indiscrete look at it. here is what I discovered. Active sensors (rotation sensor, light sensor) communicate with RCX through a two phases scheme: during 2. 9ms, RCX powers sensor (+8V), then during about 100 µs RCX reads analog value returned by sensor. During read phase, no power is provided to sensor, and this one has to live on its own reserve. This is done by storing energy in a capacitor during power phase. Here is a zoom on read phas of a rotation sensor. Numerous traces are accumulated over some time while rotating axle of sensor. You can see that sensor communicates with RCX through a 4 levels code. The voltages I measured for this levels are: These values seem a bit low when compared to Michael Gasperi`s (see his rotation sensor page ), perhaps my batteries were exhausted. You can also see that there is some jitter in read phase duration (between 90 µs and 125 µs) As the axle is rotated clockwise, output cycles througs steps 1 > 2 > 3 > 4 > 1, and through steps 1 > 4 > 3 > 2 > 1 when rotated ccw.

This enables RCX to determinate rotation direction. As pointed out by here by JG rgen Stuber, we have here the first problem of rotation sensor: during transition between step 3 and 4, output crosses voltage of level 2, and between step 1 and 2, output crosses voltage of level 4. Since this transition takes some time, there is a probability that it happens just when RCX samples value.

I tried to determine sampling time, it seems to take place about 60 µs after beginning of read phase. Here is such a transitionbetween step 3 and step 4. We can see that transition time across 3. 3V (step 2) can be evaluated to 1 µs. Sampling is done every 3 ms, probability of misread can be evaluated to about 1/3000 at most. Some alternative RCX programming languages (legOS and leJOS) perform two consecutive readings and almost eliminate this problem at the cost of halving maximum rotation speed.

To obtain this trace, I simply rotated sensor by hand very slowly till I reached transition between steps. And instead of having a sudden jump between two values, I got a stable oscilloscope trace (hand shaking apart) showing a transition each 3ms!

And moving VERY little my hand I could modify the position of this transition, and especially place it just at sampling point - and counter began to jump between values. It seems that very close to transition position, there is synchronisation with power/read cycle, and this increases the previous problem: there is a lot of transitions instead of only one - and when rotating very slowly this transition is doomed to occur at sampling point and cause misread.

Note that even double sampling as performed by legOS and leJOS has no guarantee to give correct answer: if rotation is very slow two successive reads will happen during transition. To go further, I needed to look inside the sensor. Prying it open proved painful. I first cut the blue tabs below the baseplate, but sensor didn`t open. It seems that some tabs are glued or heat soldered, so I had to resort to brute force methods and cut everywhere between dark grey and blue parts.

Moreover the wire is locked tight in upper part by a peg belonging to grey plate, and I had to cut that peg too. D1, D2 rectify power supply, C1 filters it. K1 and K2 are two opto-forks (marked S89, I didn`t found exact part type), one side contains an infra-red led, the other side a phototransistor.

Blade of propellar shape part can interrupt infrared beam of K1, K2, both or none, providing the four phases of the returned value. Since there are 4 blades, we obtain 16 steps per turn. IR leds receive power through R1 (about 5mA). The node be 🔗 External reference