Light Bulb Pirani Gage Project

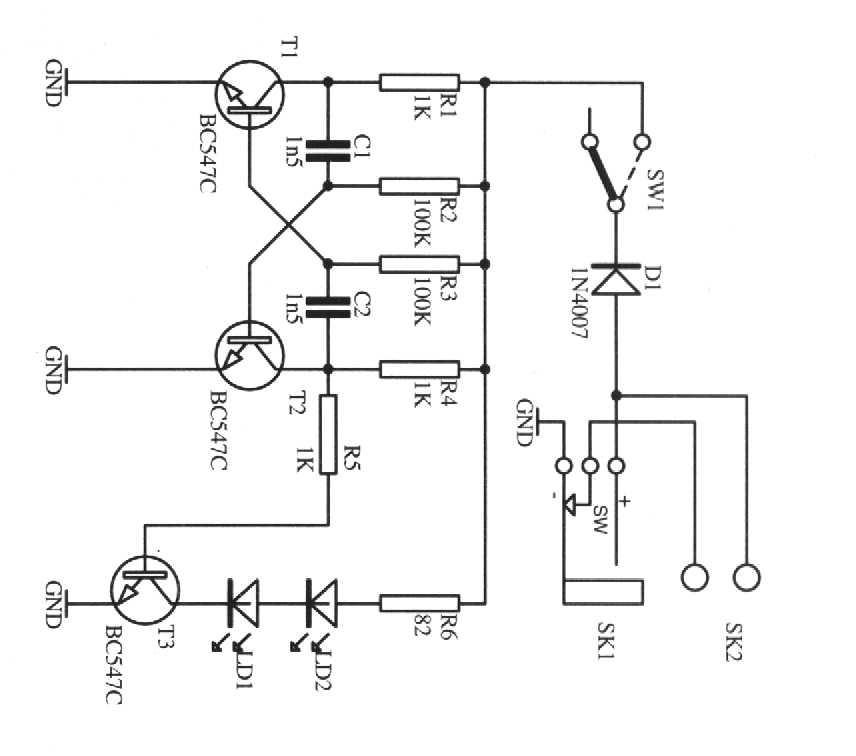

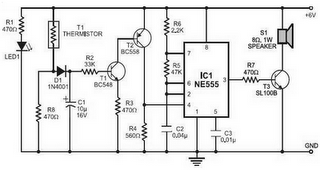

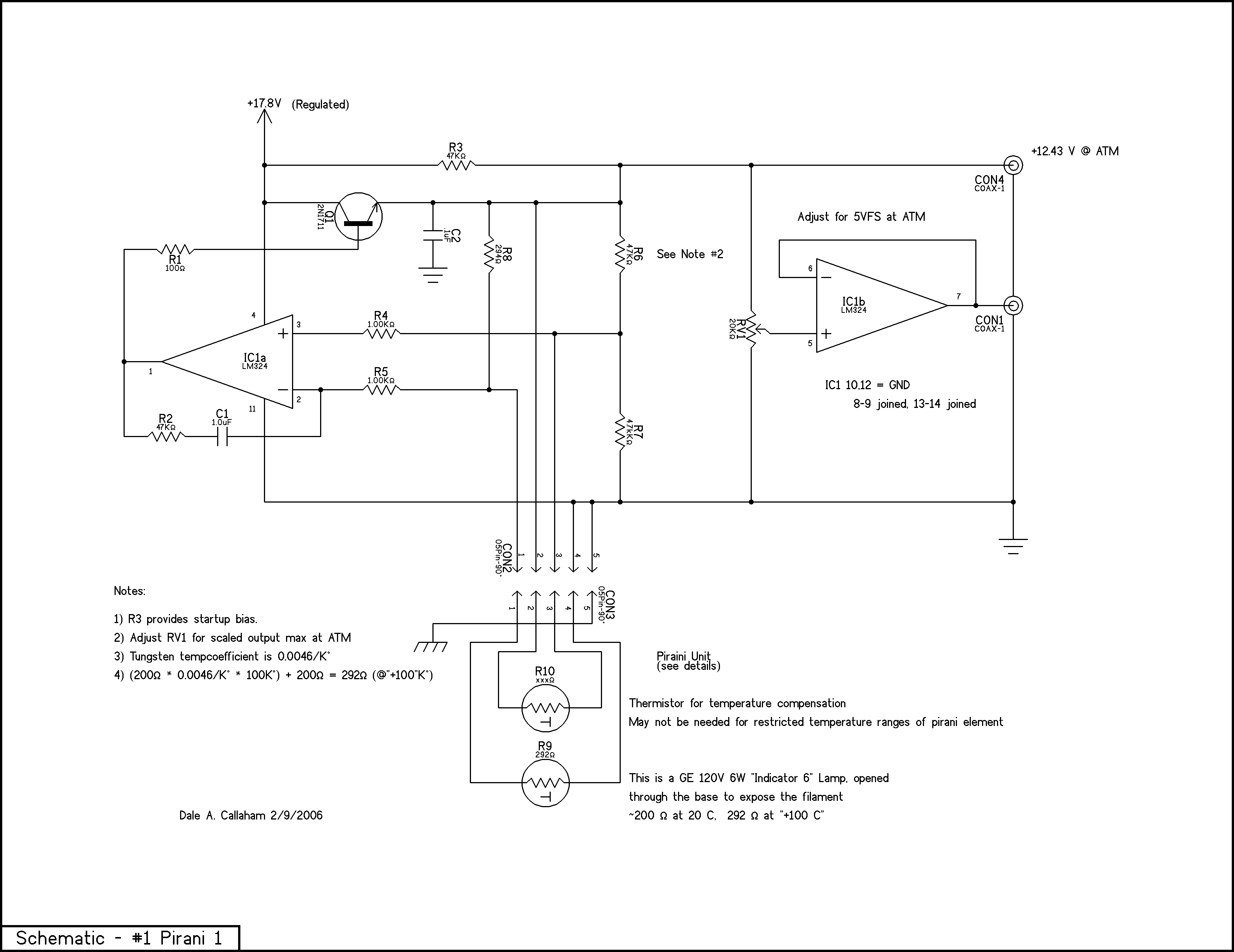

The principle is that the resistance of metals increases at higher temperatures, and a heated wire suspended in a gas will lose heat by conduction and convection in proportion to the number of gas molecules present; thus, the heat loss is proportional to pressure. One effective method to measure heat loss is by determining the voltage required to maintain the filament at a fixed temperature. The wire has a positive temperature coefficient, and knowing the resistance at ambient temperature allows for the calculation of the wire's resistance at a selected elevated temperature. When a Wheatstone Bridge is configured with a reference resistor, equal in value to the resistance that the filament will achieve at an elevated temperature, the bridge will be out of balance at ambient temperature since these resistances are unequal (as are the insensitive resistors in the other leg of the bridge, as depicted in the schematic). This imbalance can be utilized to control the voltage applied to the Wheatstone bridge; an increased voltage will heat the filament, increasing its resistance, while the reference resistor (which is less temperature sensitive) remains stable. The bridge and feedback circuit stabilize when the filament resistance reaches the value of the paired reference, assuming that the other leg of the bridge uses equal value resistors as illustrated in the schematic. The voltage applied to the bridge at balance at atmospheric pressure serves as the "ATM" calibration point. As the pressure surrounding the filament decreases, less heat is lost compared to atmospheric pressure, resulting in a lower voltage requirement from the bridge circuit to maintain the filament at the appropriate resistance (and temperature); thus, the bridge excitation voltage reflects the pressure, decreasing with reduced pressure. The elevated filament temperature can be selected to ensure it is hot enough to burn off any contaminants without glowing incandescently. In all cases, the filament should maintain this temperature to ensure robustness and prevent burnout. The filaments of optimal gauges are often composed of platinum wire alloys, although tungsten, in the form of a light bulb filament, also serves effectively as a sensor. This design utilizes the tungsten filament of the GE "Indicator-6" 6W/120V lamp as a vacuum sensor. This lamp exhibits a favorable balance of characteristics for this application; the 120V, low wattage filament can operate in the <20V range at the modest filament temperatures used without significant power consumption. To construct the sensor, the aluminum screw base is removed with fine wire cutters, exposing the base of the glass envelope. Some resin may need to be scraped away to reveal a small central tubular stem of heat-sealed glass, which is visible at the center. This stem is where the lamp envelope was evacuated and/or backfilled. A diamond or tungsten scribe can be employed to score the stem, which can then be snapped off, allowing the interior of the lamp and filament to communicate with the outside environment; the opened bulb must be mounted inside the vacuum system, and leads connected to "feedthroughs" that link to the measuring circuit externally. In the following formula, let R represent the physical property to be measured and T be the temperature at which the property is measured. T0 is the reference temperature, and ΔT is the difference between T and T0. Finally, α is the (linear) temperature coefficient. Given these definitions, the physical property is: The Wheatstone Bridge consists of the R8-R9 pair for one leg and the R6-R7 pair for the fixed reference legs. The junction of these bridge pairs is compared by the amplifier IC1a, and the error signal when R8 ≠ R9 drives the transistor Q1 to provide the bias to the bridge array. The error amplifier output will become positive when the negative input is below the positive input.

The described circuit operates on the principle of thermal resistance change in response to varying gas pressures. The Wheatstone Bridge configuration is critical in ensuring precise measurement of the filament's resistance, which is directly influenced by the ambient pressure. The application of a feedback mechanism through the error amplifier allows for real-time adjustments to maintain the filament at the desired temperature, facilitating accurate pressure readings.

The choice of materials, such as tungsten or platinum wire alloys for the filament, is significant due to their thermal properties and stability. The construction process, including the removal of the lamp base and sealing of the glass envelope, is vital for ensuring that the sensor can accurately respond to external pressure changes without contamination from the environment.

The calibration of the sensor is established at atmospheric pressure, providing a reference point for subsequent measurements. As pressure decreases, the relationship between the voltage applied to the Wheatstone Bridge and the corresponding pressure becomes inversely proportional, allowing for a straightforward interpretation of the voltage output as a measure of vacuum levels.

This sensor design exemplifies a robust and efficient method for measuring vacuum pressure, with careful attention to material selection, circuit configuration, and calibration processes ensuring high accuracy and reliability in various applications.The principle is that the resistance of metals increases at higher temperatures and a heated wire suspended in a gas will lose heat by conduction and convection in proportion to the number of gas molecules present; the heat loss is thus proportinal to pressure. One of the best ways to measure the heat loss is to measure the voltage required to mai ntain the filament at a fixed temperature. The wire has a positive coefficient of temperature and, given the value of resistance at ambient temperature, one can calculate the resistance of the wire at a chosen elevated temperature. If a Wheatstone Bridge is configured so that a reference resistor, in value equal to the resistance that the filament will reach at an elevated temperature, is paired with the sensor filament, the bridge will be out of balance at ambient temperature since these resistances are not equal (as are the insensitive resistors in the other bridge leg - as shown in the schematic).

If this imbalance is used to control a voltage applied to the Wheatstone bridge, an increased voltage will heat the filament and its resistance will increase, while the reference resistor (far less temperature sensitive) remains stable. The bridge and feedback circuit stabilize when the filament resistance reaches the value of the paired reference; this assumes that the other leg of the bridge uses equal value resistors as shown in the schematic.

The voltage being applied to the bridge at balance at atmospheric pressure becomes the "ATM" calibration point. As the pressure surronding the filament is reduced, less heat is lost than at atmospheric pressure, and less voltage is needed by the bridge circuit to maintain the filament at the correct resistance (and temperature); the bridge excitation voltage is then an indication of the pressure, the voltage decreasing with decreasing pressure.

The elevated filament temperature can be selected so that the filament is hot enough to burn off any contaminants that may reach it, but not incandescent. In all cases the filament will be this temperature and will be robust and avoid burnout. The filaments of the best gages are often formed of platinum wire alloys, but tungsten, in the form of a light bulb filament makes a nice sensor as well.

This is a simple single-element sensor that utilizes the tungsten filament of the GE "Indicator-6" 6W/120V lamp as a sensor of vacuum. This lamp has good balance of characteristics for this application; the 120V, low wattage lamp filament can operate in the <20V range at the modest filament temperatures used without much power consumption.

To make the sensor, the aluminum screw base is cut off with fine wirecutters exposing the base of the glass envelope as shown. There is some resin that will need to be scraped away. There is a small central tubular stem of heat sealed glass visible at the center. This is where the lamp envelope was evacuated and/or backfilled. A diamond or tungsten scribe can be used to score the stem and it can then be snapped off (as shown), allowing the interior of the lamp and filament to communicate with the "outside" environment; the opened bulb needs to be mounted inside the vacuum system and the leads connected to "feedthroughs" that connect to the measuring circuit externally.

In the following formula, let R be the physical property to be measured and T be the temperature at which the property is measured. T0 is the reference temperature, and ”T is the difference between T and T0. Finally, ± is the (linear) temperature coefficient. Given these definitions, the physical property is: The Wheatstone Bridge is the R8-R9 pair for one leg and R6-R7 pair for the fixed reference legs.

The junction of these bridge pairs is compared by the amplifier IC1a, and the error signal when R8‰ R9 drives the transistor Q1 to provide the bias to the bridge array. The error amplifier output will go positive when the (-)input is below the (+)input 🔗 External reference

The described circuit operates on the principle of thermal resistance change in response to varying gas pressures. The Wheatstone Bridge configuration is critical in ensuring precise measurement of the filament's resistance, which is directly influenced by the ambient pressure. The application of a feedback mechanism through the error amplifier allows for real-time adjustments to maintain the filament at the desired temperature, facilitating accurate pressure readings.

The choice of materials, such as tungsten or platinum wire alloys for the filament, is significant due to their thermal properties and stability. The construction process, including the removal of the lamp base and sealing of the glass envelope, is vital for ensuring that the sensor can accurately respond to external pressure changes without contamination from the environment.

The calibration of the sensor is established at atmospheric pressure, providing a reference point for subsequent measurements. As pressure decreases, the relationship between the voltage applied to the Wheatstone Bridge and the corresponding pressure becomes inversely proportional, allowing for a straightforward interpretation of the voltage output as a measure of vacuum levels.

This sensor design exemplifies a robust and efficient method for measuring vacuum pressure, with careful attention to material selection, circuit configuration, and calibration processes ensuring high accuracy and reliability in various applications.The principle is that the resistance of metals increases at higher temperatures and a heated wire suspended in a gas will lose heat by conduction and convection in proportion to the number of gas molecules present; the heat loss is thus proportinal to pressure. One of the best ways to measure the heat loss is to measure the voltage required to mai ntain the filament at a fixed temperature. The wire has a positive coefficient of temperature and, given the value of resistance at ambient temperature, one can calculate the resistance of the wire at a chosen elevated temperature. If a Wheatstone Bridge is configured so that a reference resistor, in value equal to the resistance that the filament will reach at an elevated temperature, is paired with the sensor filament, the bridge will be out of balance at ambient temperature since these resistances are not equal (as are the insensitive resistors in the other bridge leg - as shown in the schematic).

If this imbalance is used to control a voltage applied to the Wheatstone bridge, an increased voltage will heat the filament and its resistance will increase, while the reference resistor (far less temperature sensitive) remains stable. The bridge and feedback circuit stabilize when the filament resistance reaches the value of the paired reference; this assumes that the other leg of the bridge uses equal value resistors as shown in the schematic.

The voltage being applied to the bridge at balance at atmospheric pressure becomes the "ATM" calibration point. As the pressure surronding the filament is reduced, less heat is lost than at atmospheric pressure, and less voltage is needed by the bridge circuit to maintain the filament at the correct resistance (and temperature); the bridge excitation voltage is then an indication of the pressure, the voltage decreasing with decreasing pressure.

The elevated filament temperature can be selected so that the filament is hot enough to burn off any contaminants that may reach it, but not incandescent. In all cases the filament will be this temperature and will be robust and avoid burnout. The filaments of the best gages are often formed of platinum wire alloys, but tungsten, in the form of a light bulb filament makes a nice sensor as well.

This is a simple single-element sensor that utilizes the tungsten filament of the GE "Indicator-6" 6W/120V lamp as a sensor of vacuum. This lamp has good balance of characteristics for this application; the 120V, low wattage lamp filament can operate in the <20V range at the modest filament temperatures used without much power consumption.

To make the sensor, the aluminum screw base is cut off with fine wirecutters exposing the base of the glass envelope as shown. There is some resin that will need to be scraped away. There is a small central tubular stem of heat sealed glass visible at the center. This is where the lamp envelope was evacuated and/or backfilled. A diamond or tungsten scribe can be used to score the stem and it can then be snapped off (as shown), allowing the interior of the lamp and filament to communicate with the "outside" environment; the opened bulb needs to be mounted inside the vacuum system and the leads connected to "feedthroughs" that connect to the measuring circuit externally.

In the following formula, let R be the physical property to be measured and T be the temperature at which the property is measured. T0 is the reference temperature, and ”T is the difference between T and T0. Finally, ± is the (linear) temperature coefficient. Given these definitions, the physical property is: The Wheatstone Bridge is the R8-R9 pair for one leg and R6-R7 pair for the fixed reference legs.

The junction of these bridge pairs is compared by the amplifier IC1a, and the error signal when R8‰ R9 drives the transistor Q1 to provide the bias to the bridge array. The error amplifier output will go positive when the (-)input is below the (+)input 🔗 External reference