Micro-Ohm Meter Senior Project Page

A digital micro-ohm meter is essential for assessing the condition of shunts used in the Electrochemical Analysis & Diagnostics Laboratory (EADL) at Argonne National Laboratories. A shunt is essentially a small resistor utilized for current measurement. The micro-ohmmeter will apply 0.5A of current through smaller shunts and 10A through larger ones. When current flows through a shunt, it generates a corresponding voltage. With both current and voltage known, the capabilities of the 68HC11 microcontroller will be leveraged to calculate the associated resistance. The digital micro-ohmmeter features a straightforward design, consisting of a constant current flowing into a known resistance and an unknown resistance. Once the voltage across the known resistance reaches a specific threshold, the current can be accurately calculated. Subsequently, the analog-to-digital converter (A/D) measures the voltage across the unknown shunt. These values are stored in memory, and using floating-point software, the resistance of the unknown shunt is determined by dividing the voltage by the current. This simple configuration serves as the foundation for the project. The digital micro-ohmmeter employs one bipolar junction transistor (BJT), a proportional-integral (PI) controller, and an A/D converter to maintain the constant current function. The BJT operates as a voltage-controlled switch. The predetermined voltage across the calibrated resistance is set via a front panel switch and stored in the microcontroller as the current value. The voltage measured across the shunt is divided by the obtained current value to ascertain the resistance. This resistance value is then converted to ASCII format for display on an LCD. The micro-ohm meter will be utilized by Argonne National Laboratories to validate the resistance values of shunts, offering a cost-effective solution compared to existing systems on the market.

The digital micro-ohm meter circuit integrates several key components to ensure accurate measurements and reliable performance. The primary component, the 68HC11 microcontroller, serves as the central processing unit, executing the necessary calculations and controlling the overall operation of the device. The microcontroller interfaces with a BJT, which functions as a voltage-controlled switch, enabling precise control of the current flowing through the shunt.

The circuit includes a PI controller that regulates the output current to maintain a constant level, essential for accurate resistance measurements. The A/D converter plays a crucial role in digitizing the voltage readings from the shunt, allowing the microcontroller to process these values effectively. The front panel switch allows the user to set the predetermined voltage across the known resistance, which is critical for the current calculation.

Upon applying current to the shunt, the circuit measures the resulting voltage drop. The microcontroller then computes the resistance using Ohm's law (R = V/I), where V is the measured voltage and I is the constant current. The calculated resistance value is converted into ASCII format, making it suitable for display on the LCD, providing users with a clear and readable output.

This digital micro-ohm meter is designed to be user-friendly and efficient, with a focus on minimizing costs while maintaining high accuracy and reliability. Its application in verifying shunt resistance values in a laboratory setting highlights its importance in ensuring the integrity of electrochemical measurements and diagnostics.A digital micro-ohm meter is necessary to verify the condition of shunts used in the Electrochemical Analysis & Diagnostics Laboratory (EADL) at Argonne National Laboratories. A shunt is basically a small resistor. They are used to measure current. The micro-ohmmeter will push 0. 5A of current through the smaller shunts and 10A through the larger s hunts. When a current is put through a shunt it produces a corresponding voltage. With the current and voltage known the abilities of the 68hc11 would be utilized to calculate the corresponding resistance. The digital micro-ohmmeter is very simple in design. Basically the circuit is a constant current flowing into a resistance value that is known and a resistance value that is unknown.

When the voltage across the resistance value that is known reaches a certain value, the exact current can be calculated. Now that the current is known, the A/D will find voltage across the unknown shunt. These values will be stored into memory and by using the floating point software. The look up table will be found by dividing the voltage by the current. This will find resistance in the unknown shunt. This simple set-up is the basis for our project. The digital micro-ohmmeter utilizes one BJT, a PI controller, and an analog to digital converter to provide the constant current function.

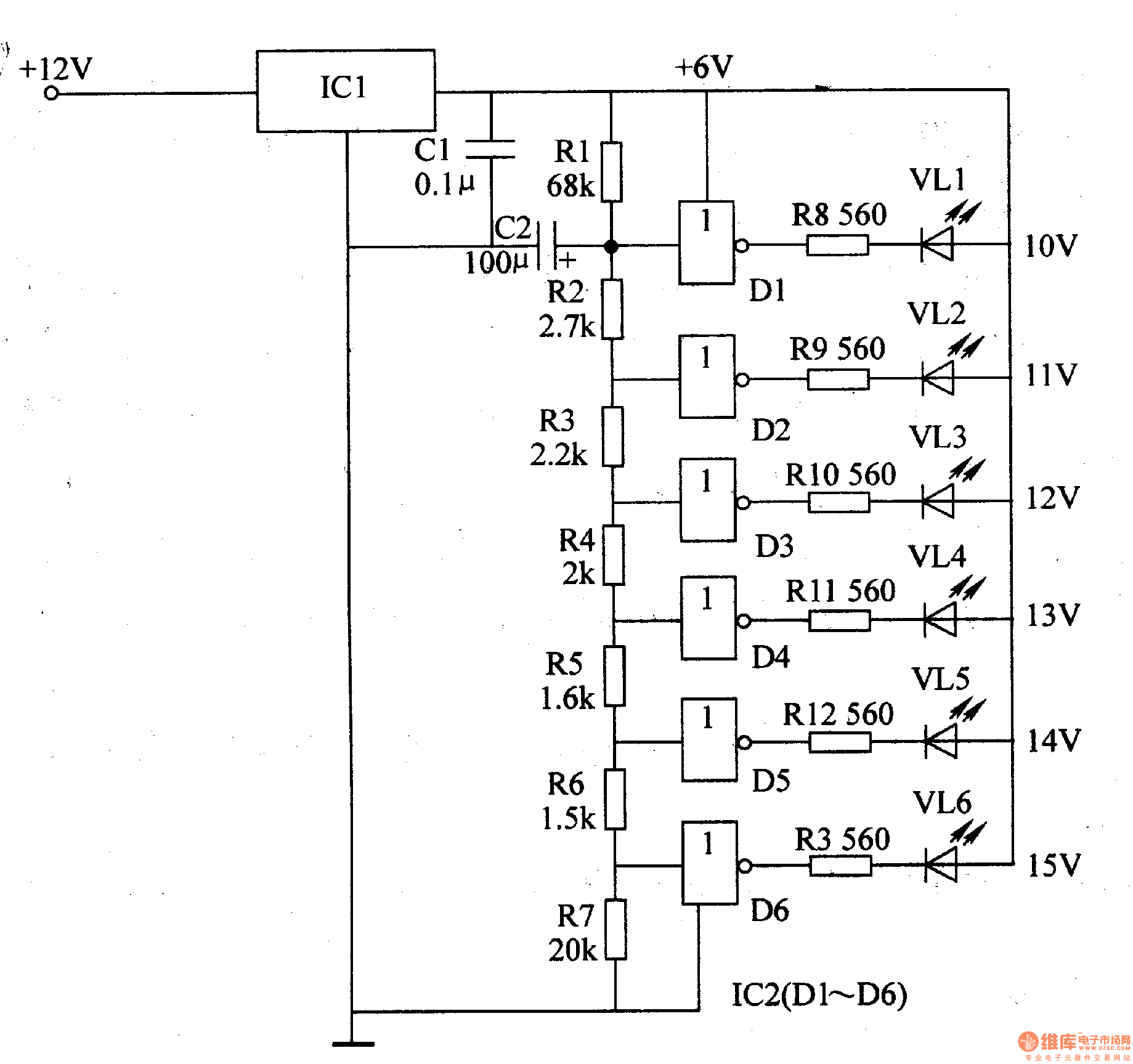

Refer to Figure below for a block diagram. Simply put, the BJT is used as a voltage controlled switch. The predetermined voltage value across the calibrated resistance is determined by the front panel switch, and is stored in the micro controller as the current value. The voltage read off of the shunt to be measured is then divided by the current value obtained to determine the resistance value.

This resistance value is then converted to ASCII in order to be displayed by the LCD. The micro-ohm meter will be used by Argonne National Laboratories to verify resistance values of shunts. This system will be far cheaper than any other system on the market. 🔗 External reference

The digital micro-ohm meter circuit integrates several key components to ensure accurate measurements and reliable performance. The primary component, the 68HC11 microcontroller, serves as the central processing unit, executing the necessary calculations and controlling the overall operation of the device. The microcontroller interfaces with a BJT, which functions as a voltage-controlled switch, enabling precise control of the current flowing through the shunt.

The circuit includes a PI controller that regulates the output current to maintain a constant level, essential for accurate resistance measurements. The A/D converter plays a crucial role in digitizing the voltage readings from the shunt, allowing the microcontroller to process these values effectively. The front panel switch allows the user to set the predetermined voltage across the known resistance, which is critical for the current calculation.

Upon applying current to the shunt, the circuit measures the resulting voltage drop. The microcontroller then computes the resistance using Ohm's law (R = V/I), where V is the measured voltage and I is the constant current. The calculated resistance value is converted into ASCII format, making it suitable for display on the LCD, providing users with a clear and readable output.

This digital micro-ohm meter is designed to be user-friendly and efficient, with a focus on minimizing costs while maintaining high accuracy and reliability. Its application in verifying shunt resistance values in a laboratory setting highlights its importance in ensuring the integrity of electrochemical measurements and diagnostics.A digital micro-ohm meter is necessary to verify the condition of shunts used in the Electrochemical Analysis & Diagnostics Laboratory (EADL) at Argonne National Laboratories. A shunt is basically a small resistor. They are used to measure current. The micro-ohmmeter will push 0. 5A of current through the smaller shunts and 10A through the larger s hunts. When a current is put through a shunt it produces a corresponding voltage. With the current and voltage known the abilities of the 68hc11 would be utilized to calculate the corresponding resistance. The digital micro-ohmmeter is very simple in design. Basically the circuit is a constant current flowing into a resistance value that is known and a resistance value that is unknown.

When the voltage across the resistance value that is known reaches a certain value, the exact current can be calculated. Now that the current is known, the A/D will find voltage across the unknown shunt. These values will be stored into memory and by using the floating point software. The look up table will be found by dividing the voltage by the current. This will find resistance in the unknown shunt. This simple set-up is the basis for our project. The digital micro-ohmmeter utilizes one BJT, a PI controller, and an analog to digital converter to provide the constant current function.

Refer to Figure below for a block diagram. Simply put, the BJT is used as a voltage controlled switch. The predetermined voltage value across the calibrated resistance is determined by the front panel switch, and is stored in the micro controller as the current value. The voltage read off of the shunt to be measured is then divided by the current value obtained to determine the resistance value.

This resistance value is then converted to ASCII in order to be displayed by the LCD. The micro-ohm meter will be used by Argonne National Laboratories to verify resistance values of shunts. This system will be far cheaper than any other system on the market. 🔗 External reference