Microscope stepper controller

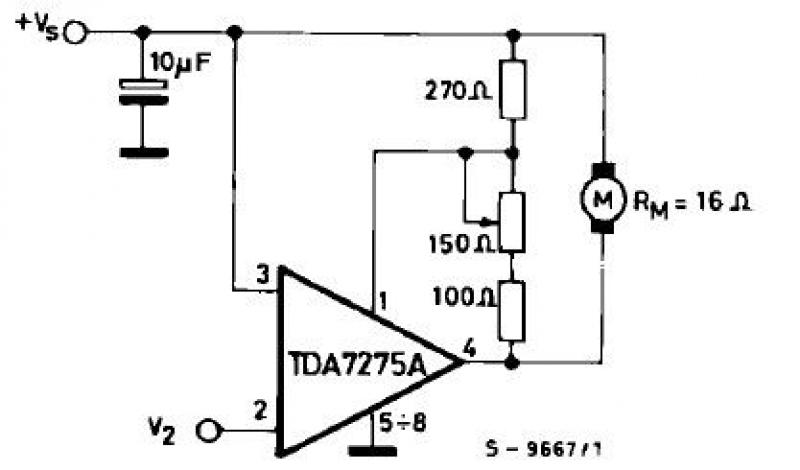

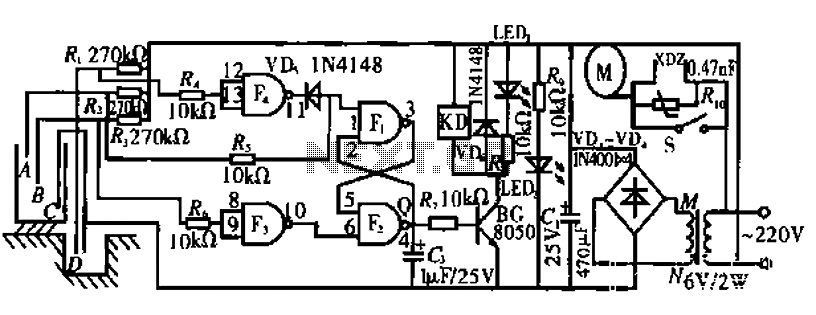

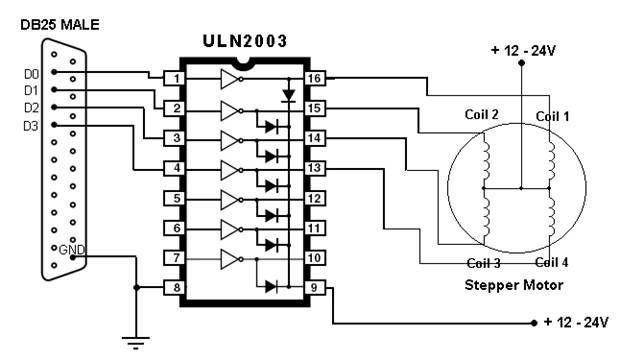

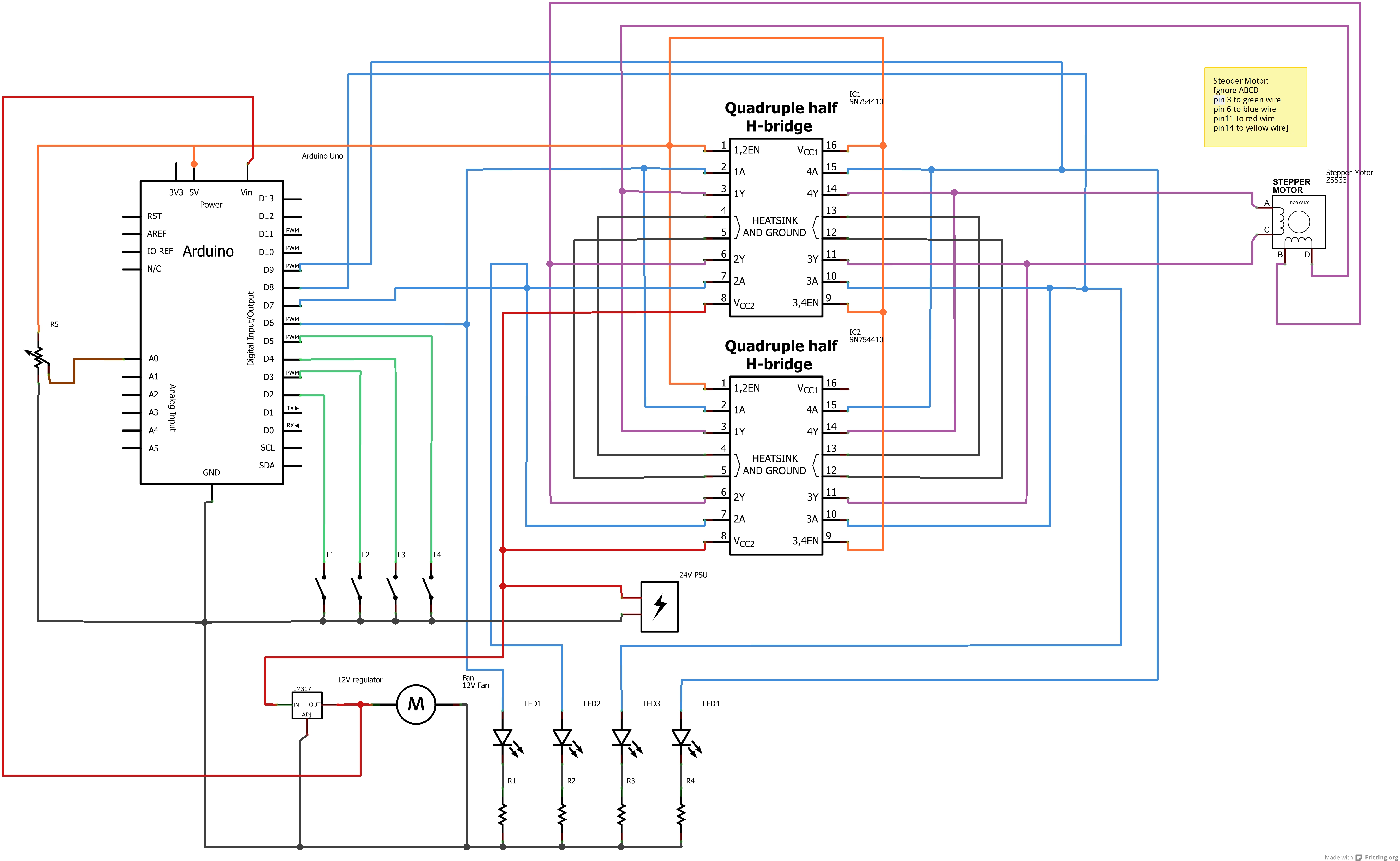

Designed for Birkbeck, the microscope controller is an open-source stepper motor driver that utilizes an Arduino Uno and an Arduino stepper motor shield to operate a Phytron ZSS32 200 1.2A 3V stepper motor. The sample port movement is facilitated by an inverted Marzhauser microscope stage, also controlled by the Arduino Uno. The Arduino drives four SN754410 quadruple half-H drivers connected in parallel. The Phytron ZSS33 stepper motors require 1.2A per phase, totaling 2.4A, which exceeds the 1A limit of a single SN754410; hence, four drivers are used in parallel. The provided schematic illustrates the final circuit controlling one of the axes, featuring only one SN754410 IC for clarity. All part numbers and connections should be verified before construction.

The circuit design for the microscope controller integrates an Arduino Uno with a stepper motor shield to control the Phytron ZSS32 stepper motor, which is essential for precise positioning in microscopy applications. The stepper motor is driven by four SN754410 integrated circuits (ICs) connected in parallel to ensure sufficient current supply, as each motor phase requires 1.2A, and the SN754410 is limited to 1A. This configuration allows for a total current capacity of 4A, meeting the motor's requirements without overheating the driver.

In the schematic, the Arduino is programmed using the Stepper library, which simplifies the control of the motor's movement. The motor is configured with 200 steps per revolution, and the control pins are assigned to digital pins 6, 7, 8, and 9 on the Arduino. The controller also incorporates limit switches connected to digital pins 2 and 3, which prevent the motor from exceeding its operational limits, ensuring that the stage does not move beyond its physical boundaries.

The software implementation involves reading the position of a joystick connected to analog pin A0. This joystick input is utilized to determine the desired position of the microscope stage. The speed of the stepper motor is dynamically adjusted based on the joystick's offset from its center position, allowing for smooth and responsive control. If the joystick is within a certain range of the center value, the motor is disabled to allow for manual adjustments without resistance from the motors.

Additional features include a dimmable LED ring light powered through the USB port of a connected PC, providing effective illumination for the sample without the high costs associated with commercial alternatives. The overall design is modular, allowing for easy integration with existing laboratory equipment, such as mass spectrometers, and is adaptable for various microscopy applications. The entire system emphasizes precision, control, and flexibility, making it suitable for advanced research in microscopy.Built for Birkbeck, the microscope controller is a open source stepper motor driver. It uses an Arduino Uno, and arduino stepper motor shield to drive a Phytron ZSS32. 200 1. 2A 3V stepper motor. To move the sample port, we use an inverted Marzhauser microscope stage, controlled by an Arduino Uno. The Arduino drives four SN754410 quadruple half h d rivers (connected in parallel). The Phytron ZSS33 stepper motors draw 1. 2 A per phase (i. e 2. 4 A) but the SN754410 is limited to 1A, hence four in parallel). The schematic below shows the final circuit, which controls one of the axes. The schematic shows only one SN754410 IC. otherwise it looks messy. I think all the part numbers and connections are correct - check before building! /* * COD (CO2Driver) */ #include // create an instance of the stepper class, specifying // the number of steps of the motor and the pins it`s // attached to, for each of the motors Stepper stepper1(200, 6, 7, 8, 9); int sensor1=A0; int sensorVal1; int sensorVal2; int defaultval1; int defaultval2; void setup() { stepper1. setSpeed(5); Serial. begin(9600); pinMode(2, INPUT); // set pin 2 to input digitalWrite(2, HIGH); // turn on pullup resistors pinMode(3, INPUT); // set pin 3 to input digitalWrite(3, HIGH); // turn on pullup resistors pinMode(A5, INPUT); // Set A5 to input digitalWrite(A5, HIGH); // Turn on pull up resistors defaultval1=analogRead(sensor1); //Get the centre voltage of the joystick } void loop() { if (analogRead(5) < 100) { Xmove(); } } void Xmove(){ //Define the centre position for joystick // defaultval1=503; // get the current joystick position sensorVal1=analogRead(sensor1); //Speed of the motor is proportional to offset of the joystick int offset1=defaultval1-sensorVal1; int spd1=1+abs(offset1)/4; //Axis 1 -ve direction - stop moving if limits exceeded int LIM3 = digitalRead(3); // read the input pin if (LIM3 != 0){ if (sensorVal1 <=(defaultval1-20) { stepper1.

step(1); sensorVal1=analogRead(sensor1); stepper1. setSpeed(spd1); } } //Axis 1 +ve direction - stop moving if limits exceeded int LIM4 = digitalRead(2); // read the input pin if (LIM4 != 0){ if (sensorVal1 >= (defaultval1+20) { stepper1. step(-1); sensorVal1=analogRead(sensor1); stepper1. setSpeed(spd1); } } //When the joystick is at 0, don`t draw current. //This allows motors to be turned manually. if (sensorVal1 < (defaultval1+20) && (sensorVal1 >(defaultval1-20) { digitalWrite(6, LOW); digitalWrite(7, LOW); digitalWrite(8, LOW); digitalWrite(9, LOW); } } Built at the Open University, FLUMP (Fibre Laser Unit on a Mobile Platform) is a SPI 25 W 1090 nm infrared laser mounted in a 19" mobile rack (enabling it to be used on any mass spectrometer).

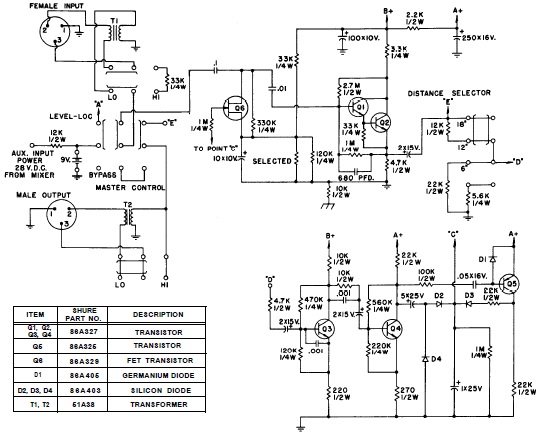

The 1090nm infrared beam is delivered via a fibre optic cable into a Leitz microscope, where it is directed to the objective, and focussed onto the sample chamber. I wrote the software to control the laser, which can operate in CW mode or a psuedo-pulse mode, with a power range of 5 mW to 24.

7 W, depending on which beam splitter is in place. Individual pulses of >50 ms are possible, which allow infrared spot dating. I also built the dimmable LED ringlight, powered through the USB port of the PC, orders of magnitude cheaper than the commercial versions! I designed and constructed most aspects of this laser, inculding the electronic control for the stepper motors on the XYZ stage, the enclosed beam delivery system, laser shielding, and Zinc Selenide windowed laser port.

Also built at the OU, DiLBeRT (DIode Laser BEnch on a Rolling Trolley) is a SPI G3 series 20W 1062 nm laser which fires through a modified defunct New Wave 213 nm laser. As with the other lasers, this is also mobile. Unlike Flump, this laser is hardware controlled; I put together the electronic control boards which communicate with the SPI hardware, modified the New Wave laser (removing the 213nm optics and installing 1062nm optics), and put

🔗 External reference

The circuit design for the microscope controller integrates an Arduino Uno with a stepper motor shield to control the Phytron ZSS32 stepper motor, which is essential for precise positioning in microscopy applications. The stepper motor is driven by four SN754410 integrated circuits (ICs) connected in parallel to ensure sufficient current supply, as each motor phase requires 1.2A, and the SN754410 is limited to 1A. This configuration allows for a total current capacity of 4A, meeting the motor's requirements without overheating the driver.

In the schematic, the Arduino is programmed using the Stepper library, which simplifies the control of the motor's movement. The motor is configured with 200 steps per revolution, and the control pins are assigned to digital pins 6, 7, 8, and 9 on the Arduino. The controller also incorporates limit switches connected to digital pins 2 and 3, which prevent the motor from exceeding its operational limits, ensuring that the stage does not move beyond its physical boundaries.

The software implementation involves reading the position of a joystick connected to analog pin A0. This joystick input is utilized to determine the desired position of the microscope stage. The speed of the stepper motor is dynamically adjusted based on the joystick's offset from its center position, allowing for smooth and responsive control. If the joystick is within a certain range of the center value, the motor is disabled to allow for manual adjustments without resistance from the motors.

Additional features include a dimmable LED ring light powered through the USB port of a connected PC, providing effective illumination for the sample without the high costs associated with commercial alternatives. The overall design is modular, allowing for easy integration with existing laboratory equipment, such as mass spectrometers, and is adaptable for various microscopy applications. The entire system emphasizes precision, control, and flexibility, making it suitable for advanced research in microscopy.Built for Birkbeck, the microscope controller is a open source stepper motor driver. It uses an Arduino Uno, and arduino stepper motor shield to drive a Phytron ZSS32. 200 1. 2A 3V stepper motor. To move the sample port, we use an inverted Marzhauser microscope stage, controlled by an Arduino Uno. The Arduino drives four SN754410 quadruple half h d rivers (connected in parallel). The Phytron ZSS33 stepper motors draw 1. 2 A per phase (i. e 2. 4 A) but the SN754410 is limited to 1A, hence four in parallel). The schematic below shows the final circuit, which controls one of the axes. The schematic shows only one SN754410 IC. otherwise it looks messy. I think all the part numbers and connections are correct - check before building! /* * COD (CO2Driver) */ #include

step(1); sensorVal1=analogRead(sensor1); stepper1. setSpeed(spd1); } } //Axis 1 +ve direction - stop moving if limits exceeded int LIM4 = digitalRead(2); // read the input pin if (LIM4 != 0){ if (sensorVal1 >= (defaultval1+20) { stepper1. step(-1); sensorVal1=analogRead(sensor1); stepper1. setSpeed(spd1); } } //When the joystick is at 0, don`t draw current. //This allows motors to be turned manually. if (sensorVal1 < (defaultval1+20) && (sensorVal1 >(defaultval1-20) { digitalWrite(6, LOW); digitalWrite(7, LOW); digitalWrite(8, LOW); digitalWrite(9, LOW); } } Built at the Open University, FLUMP (Fibre Laser Unit on a Mobile Platform) is a SPI 25 W 1090 nm infrared laser mounted in a 19" mobile rack (enabling it to be used on any mass spectrometer).

The 1090nm infrared beam is delivered via a fibre optic cable into a Leitz microscope, where it is directed to the objective, and focussed onto the sample chamber. I wrote the software to control the laser, which can operate in CW mode or a psuedo-pulse mode, with a power range of 5 mW to 24.

7 W, depending on which beam splitter is in place. Individual pulses of >50 ms are possible, which allow infrared spot dating. I also built the dimmable LED ringlight, powered through the USB port of the PC, orders of magnitude cheaper than the commercial versions! I designed and constructed most aspects of this laser, inculding the electronic control for the stepper motors on the XYZ stage, the enclosed beam delivery system, laser shielding, and Zinc Selenide windowed laser port.

Also built at the OU, DiLBeRT (DIode Laser BEnch on a Rolling Trolley) is a SPI G3 series 20W 1062 nm laser which fires through a modified defunct New Wave 213 nm laser. As with the other lasers, this is also mobile. Unlike Flump, this laser is hardware controlled; I put together the electronic control boards which communicate with the SPI hardware, modified the New Wave laser (removing the 213nm optics and installing 1062nm optics), and put

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713