network wiring tester schematic circuit

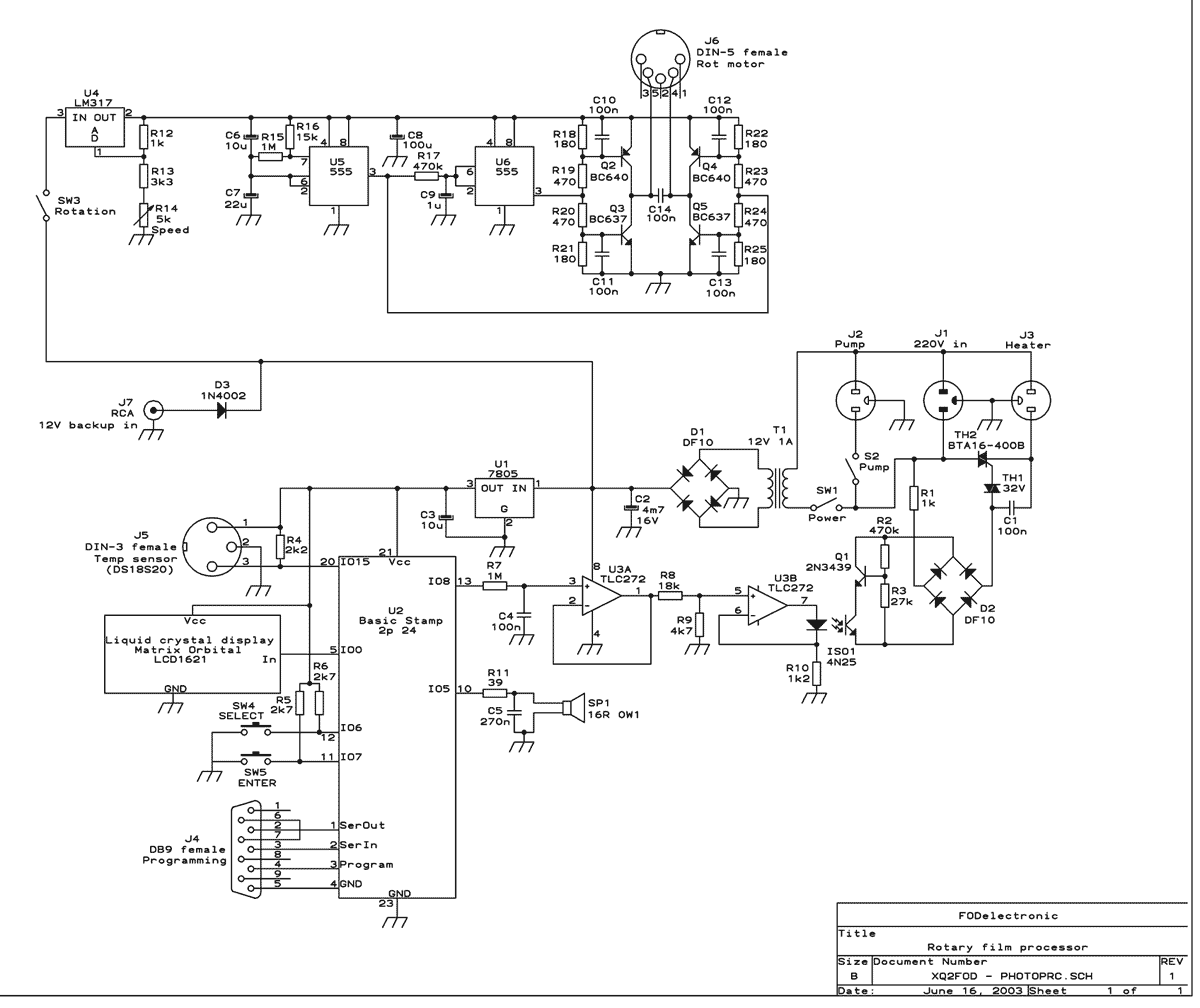

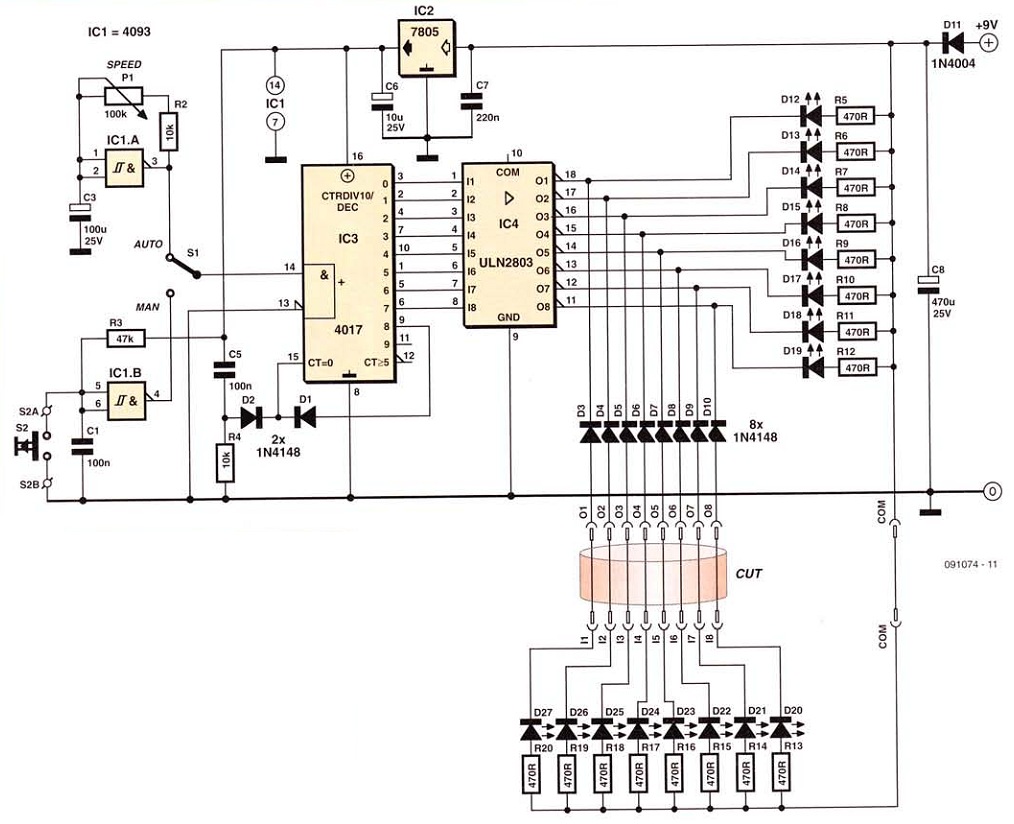

This network wiring tester consists of two components: a transmitter unit, which is powered and installed at the network's starting point, and a passive receiver unit that can be moved from socket to socket. Both units contain eight LEDs, labeled 1 to 8. By pressing a button in manual mode or using a clock in automatic mode, the eight LEDs illuminate sequentially on the transmitter unit, and they should replicate this sequence on the receiver unit. Observing the LED lighting cycle on the receiver unit allows for the immediate identification of crossed wires, open circuits (where the relevant LED does not light up), or shorts (where two or more LEDs illuminate simultaneously). The transmitter unit features a straightforward circuit with a Schmitt-input NAND gate (IC1A) configured as a multivibrator, with its speed adjustable via potentiometer P1. IC1B serves as a debounce circuit for button S2, utilized in manual mode. Switch S1 allows the output from either IC1A or IC1B to be applied to the input of IC3, a decade counter that counts up to eight due to its Q8 output being connected back to its reset input. The outputs of the counter cannot directly drive LEDs, especially over potentially hazardous wiring, so a ULN2803 is employed to control the outputs. This integrated circuit features eight Darlington transistors, each capable of switching up to 500 mA, which drive the eight LEDs (D12-D19) on the transmitter unit and send signals to the socket with contacts 01-08, which must be connected to the wiring to be tested. The receiver unit, located at the other end of the cable, contains eight LEDs (D20-D27) and their current-limiting resistors. A common connection between the transmitter and receiver is necessary for proper operation. In cases of screened network wiring, the screen can serve this purpose. Alternatively, the earth wire from the electrical installation may be used. If neither option is available, a separate lead must be run for this connection. The transmitter unit is powered by a plug adapter providing approximately 9V at around 10 mA. The supply for IC1 and IC3 is regulated to 5V, although this regulation is not strictly necessary. For occasional use, a 9V battery can be utilized. If the device is intended solely for testing network wiring, contacts 01-08 and 11-18 should be configured as RJ45 sockets, with the common connection linked to their screening contact. It is essential to maintain consistent numbering for the LEDs on both transmitter and receiver units, and ensure that the LEDs are arranged in the correct order for automatic mode operation.

The network wiring tester is designed to simplify the process of diagnosing wiring issues in network installations. The transmitter unit's circuitry is engineered to provide a reliable and adjustable signal output, allowing for flexibility in testing modes. The use of a Schmitt trigger in the multivibrator configuration enhances the stability of the output signal, ensuring that the LEDs light up in a clear and discernible sequence. The debounce circuit is crucial for preventing false triggering during manual mode operation, which can occur due to mechanical switch bounce.

The ULN2803 integrated circuit is a robust solution for driving the LEDs, as it can handle higher current loads without risking damage to the LEDs or the circuit itself. This is particularly important in scenarios where shorts or other wiring faults could lead to excessive current draw. The design also incorporates safety measures to protect the circuit from potential damage while allowing for effective testing of the wiring.

The receiver unit's simplicity, with its eight LEDs and current-limiting resistors, allows for straightforward visual feedback during testing. The requirement for a common connection underscores the importance of grounding in network installations, ensuring that the testing process provides accurate results. The flexibility in power supply options, including the use of a 9V battery, adds to the tester's versatility, making it suitable for various testing environments.

In summary, this network wiring tester is an essential tool for professionals in the field of electronics and networking, providing a clear and efficient means of identifying wiring issues through a well-designed LED signaling system.This network wiring tester comprises two elements, a transmitter unit, powered and fitted at the network start point, and a receiver unit, passive, which can be moved around from socket to socket. Each of these units carries eight LEDS, identically labelled 1 to 8. By operating a push-button in manual mode, or using a clock in automatic, the eight LEDs light up in sequence

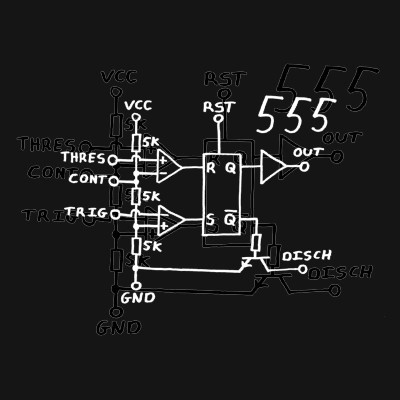

on the transmitter unit and obviously they should do the same on the receiver unit. In this way, just by watching the LED lighting cycle on the receiver unit, you can immediately spot any crossed wires, as well as any open circuits (the relevant LED never lights up) or shorts (two or more LEDs light at the same time). The transmitter unit circuit is simple` The Schmitt-input NAND gate lCl. A is wired as a multi-vibrator, whose speed can be adjusted using Pl, while lCl. B is wired as a simple debounce circuit for button 52, used in manual mode. Switch 51 lets you apply the output of one or the other of these to the input of lC3 ² a decade counter lC, which here we force to count up to eight by connecting its Q8 output back to its reset input.

Its out Puts are not capable of driving LEDs, especially over wiring that be dangerous` for them (a short, for example), so a ULN2803 is used to drive the outputs. This integrated network of eight Darlington transistors, each capable of switching up to 500 mA, drives the eight LED5 fitted to the transmitter unit (D12-D19) and feeds its signals to the socket comprising contacts 01-08, to which the wiring to be tested must be connected.

At the other end of the cable` via the socket comprising contacts l1-18, is the receiver unit which contains just eight LEDs (D20-D27) and their current limiting resistors. For the latter to work, there obviously needs to be a common connection between transmitter and receiver.

In the case of screened network wiring, the screen can be used for this purpose. Another solution consists of using the earth wire of the electrical installation to fulfilthe same function. But if neither of these solutions is feasible, then you`ll have to resign your self to running a flying lead for this purpose.

The transmitter unit power supply is obtained from a plugtop` adapter supplying around 9V at around 10 mA or so. The supply to lCl and lC3 is regulated at 5 V, even though it`s not strictly necessary. For occasional short use, a 9 V battery could be used. lf the project is intended solely for testing network wiring, 01-08 and l1-18 will be in the form of RJ45 sockets and COM will be connected to their screening contact.

Take care to stick to the same numbering for the LEDs on the transmitter and receiver units, and if the project is going to be used in automatic mode, that the LEDs are in the correct order. 🔗 External reference

The network wiring tester is designed to simplify the process of diagnosing wiring issues in network installations. The transmitter unit's circuitry is engineered to provide a reliable and adjustable signal output, allowing for flexibility in testing modes. The use of a Schmitt trigger in the multivibrator configuration enhances the stability of the output signal, ensuring that the LEDs light up in a clear and discernible sequence. The debounce circuit is crucial for preventing false triggering during manual mode operation, which can occur due to mechanical switch bounce.

The ULN2803 integrated circuit is a robust solution for driving the LEDs, as it can handle higher current loads without risking damage to the LEDs or the circuit itself. This is particularly important in scenarios where shorts or other wiring faults could lead to excessive current draw. The design also incorporates safety measures to protect the circuit from potential damage while allowing for effective testing of the wiring.

The receiver unit's simplicity, with its eight LEDs and current-limiting resistors, allows for straightforward visual feedback during testing. The requirement for a common connection underscores the importance of grounding in network installations, ensuring that the testing process provides accurate results. The flexibility in power supply options, including the use of a 9V battery, adds to the tester's versatility, making it suitable for various testing environments.

In summary, this network wiring tester is an essential tool for professionals in the field of electronics and networking, providing a clear and efficient means of identifying wiring issues through a well-designed LED signaling system.This network wiring tester comprises two elements, a transmitter unit, powered and fitted at the network start point, and a receiver unit, passive, which can be moved around from socket to socket. Each of these units carries eight LEDS, identically labelled 1 to 8. By operating a push-button in manual mode, or using a clock in automatic, the eight LEDs light up in sequence

on the transmitter unit and obviously they should do the same on the receiver unit. In this way, just by watching the LED lighting cycle on the receiver unit, you can immediately spot any crossed wires, as well as any open circuits (the relevant LED never lights up) or shorts (two or more LEDs light at the same time). The transmitter unit circuit is simple` The Schmitt-input NAND gate lCl. A is wired as a multi-vibrator, whose speed can be adjusted using Pl, while lCl. B is wired as a simple debounce circuit for button 52, used in manual mode. Switch 51 lets you apply the output of one or the other of these to the input of lC3 ² a decade counter lC, which here we force to count up to eight by connecting its Q8 output back to its reset input.

Its out Puts are not capable of driving LEDs, especially over wiring that be dangerous` for them (a short, for example), so a ULN2803 is used to drive the outputs. This integrated network of eight Darlington transistors, each capable of switching up to 500 mA, drives the eight LED5 fitted to the transmitter unit (D12-D19) and feeds its signals to the socket comprising contacts 01-08, to which the wiring to be tested must be connected.

At the other end of the cable` via the socket comprising contacts l1-18, is the receiver unit which contains just eight LEDs (D20-D27) and their current limiting resistors. For the latter to work, there obviously needs to be a common connection between transmitter and receiver.

In the case of screened network wiring, the screen can be used for this purpose. Another solution consists of using the earth wire of the electrical installation to fulfilthe same function. But if neither of these solutions is feasible, then you`ll have to resign your self to running a flying lead for this purpose.

The transmitter unit power supply is obtained from a plugtop` adapter supplying around 9V at around 10 mA or so. The supply to lCl and lC3 is regulated at 5 V, even though it`s not strictly necessary. For occasional short use, a 9 V battery could be used. lf the project is intended solely for testing network wiring, 01-08 and l1-18 will be in the form of RJ45 sockets and COM will be connected to their screening contact.

Take care to stick to the same numbering for the LEDs on the transmitter and receiver units, and if the project is going to be used in automatic mode, that the LEDs are in the correct order. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713