NTC protection circuit three-phase asynchronous motors

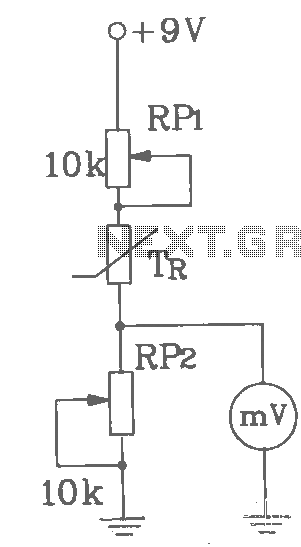

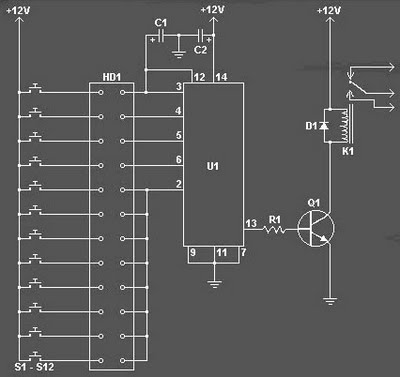

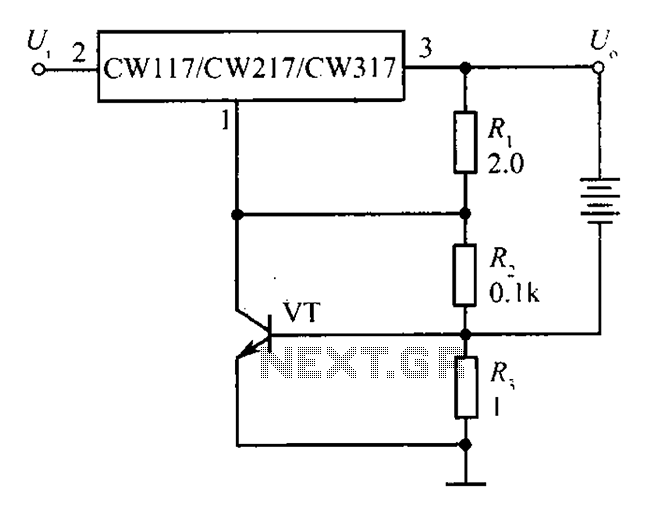

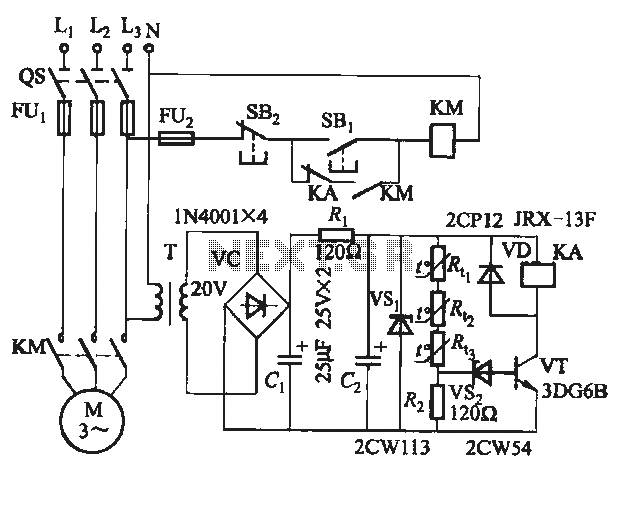

The semiconductor thermistor is an embedded thermal protection element that is sensitive to temperature, with a temperature error of 5 degrees. It offers reliability, a small size (diameter 3.5 mm), and ease of installation, making it suitable for embedding in winding applications. This thermistor effectively monitors the temperatures of electrical winding systems. It is positioned close to the wire of three-phase stator windings and is secured with epoxy cement. The thermistor can be of two types: negative temperature coefficient (NTC) thermistors and positive temperature coefficient (PTC) thermistors. The circuit is illustrated in Figure 4-1, where Figures 4-1 (b) and (c) depict only the protection circuits, while the main circuit is not shown. The protection circuit consists of a switch circuit using a single tube amplifier. The thermistor is paired with resistors R1 and R2, with the recommendation to use RRC6 type or MF-15 type resistors (20 ohm, 1k ohm, 100 ohm, and 110 ohm at approximately 0.6k).

The semiconductor thermistor serves as a critical component in thermal protection applications, particularly in electrical machinery. Its sensitivity to temperature changes makes it an effective tool for monitoring and controlling the thermal environment of electrical windings, thereby preventing overheating and potential damage. The thermistor's small size allows for easy integration into compact spaces within electrical assemblies, while its reliability ensures consistent performance over time.

In practical applications, the thermistor is positioned in close proximity to the stator windings, where it can accurately measure the temperature of the wire insulation. The use of epoxy cement for securing the thermistor enhances its durability and thermal conductivity, ensuring that temperature readings are representative of the actual winding temperatures.

The choice between NTC and PTC thermistors depends on the specific application requirements. NTC thermistors exhibit a decrease in resistance with an increase in temperature, making them suitable for applications where a drop in resistance indicates a rise in temperature. Conversely, PTC thermistors increase resistance with rising temperature, providing a protective response that can be utilized in over-temperature conditions.

The accompanying circuit diagram, as referenced in Figure 4-1, illustrates the integration of the thermistor within the thermal protection system. The protection circuit is designed to respond to temperature variations by activating a switch circuit, which can be used to disconnect power or trigger alarms when predetermined temperature thresholds are exceeded. The selection of appropriate resistors (R1 and R2) is essential for calibrating the circuit's response characteristics, ensuring that the system operates effectively within the desired thermal limits.

Overall, the semiconductor thermistor is a vital component in maintaining the operational integrity of electrical systems by providing essential thermal monitoring and protection capabilities.Semiconductor thermistor embedded thermal protection element belongs, it is sensitive to temperature, temperature error of 5 . Its reliability , small size (diameter 3. Smm), easy to install, easy to embed winding, use it as a temperature sensing element can effectively reflect the electrical winding temperatures motivation. Thermistor on the three-phase stator windings, close to the wire, with epoxy cement. Thermal resistance has a negative temperature coefficient thermistor (NTC) and positive temperature coefficient thermistor (PTC) of the points.

Circuit shown in Figure 4-1. Wherein Figure 4-1 (b), (c) only one shown protection circuits, the main circuit not shown. They are a switch circuit consisting of a single tube amplifier. Thermistor brother. , R. . , R. , The choice RRC6 type or MF-15 type (lokfl, 20 ), this thermistor in about lkfl 100 when, 110 at about 0.6k, Cl.

The semiconductor thermistor serves as a critical component in thermal protection applications, particularly in electrical machinery. Its sensitivity to temperature changes makes it an effective tool for monitoring and controlling the thermal environment of electrical windings, thereby preventing overheating and potential damage. The thermistor's small size allows for easy integration into compact spaces within electrical assemblies, while its reliability ensures consistent performance over time.

In practical applications, the thermistor is positioned in close proximity to the stator windings, where it can accurately measure the temperature of the wire insulation. The use of epoxy cement for securing the thermistor enhances its durability and thermal conductivity, ensuring that temperature readings are representative of the actual winding temperatures.

The choice between NTC and PTC thermistors depends on the specific application requirements. NTC thermistors exhibit a decrease in resistance with an increase in temperature, making them suitable for applications where a drop in resistance indicates a rise in temperature. Conversely, PTC thermistors increase resistance with rising temperature, providing a protective response that can be utilized in over-temperature conditions.

The accompanying circuit diagram, as referenced in Figure 4-1, illustrates the integration of the thermistor within the thermal protection system. The protection circuit is designed to respond to temperature variations by activating a switch circuit, which can be used to disconnect power or trigger alarms when predetermined temperature thresholds are exceeded. The selection of appropriate resistors (R1 and R2) is essential for calibrating the circuit's response characteristics, ensuring that the system operates effectively within the desired thermal limits.

Overall, the semiconductor thermistor is a vital component in maintaining the operational integrity of electrical systems by providing essential thermal monitoring and protection capabilities.Semiconductor thermistor embedded thermal protection element belongs, it is sensitive to temperature, temperature error of 5 . Its reliability , small size (diameter 3. Smm), easy to install, easy to embed winding, use it as a temperature sensing element can effectively reflect the electrical winding temperatures motivation. Thermistor on the three-phase stator windings, close to the wire, with epoxy cement. Thermal resistance has a negative temperature coefficient thermistor (NTC) and positive temperature coefficient thermistor (PTC) of the points.

Circuit shown in Figure 4-1. Wherein Figure 4-1 (b), (c) only one shown protection circuits, the main circuit not shown. They are a switch circuit consisting of a single tube amplifier. Thermistor brother. , R. . , R. , The choice RRC6 type or MF-15 type (lokfl, 20 ), this thermistor in about lkfl 100 when, 110 at about 0.6k, Cl.