OBD II Car Computer

Utilizing the OBD-II (On Board Diagnostics) protocol, live data can be retrieved from a vehicle's computer using the NerdKits microcontroller kit, as demonstrated by guest speaker Elena T., an MIT graduate from 2011. This system employs the port located beneath the steering wheel to gather various types of information, which auto mechanics commonly use for diagnosing the "Check Engine" light and conducting periodic emissions tests with onboard sensors. In this microcontroller project, the Variable Pulse Width (VPW) protocol, typically found in General Motors vehicles, is implemented. It is important to note that if this project is attempted, the vehicle may utilize a different signaling protocol that would not be compatible with the provided code. The vehicle used for this demonstration was a 1997 Chevy Cavalier, which was introduced shortly after the 1996 legislation mandating OBD-II buses in U.S. cars; however, limited sensors are accessible through the data bus. Newer vehicles may include oxygen sensors that enable miles per gallon (MPG) calculations, but for this demonstration, specific measurements were taken. Caution is advised, as there are inherent risks involved with this project. Working with car battery voltage poses potential dangers, including the risk of electrical shock or fire. Additionally, interfacing with the car's computer could lead to irreversible damage to the vehicle or its components. Drivers should prioritize road safety over circuit assembly and monitoring. Optocouplers, or opto-isolators, facilitate the transmission of information without a direct electrical connection. These components consist of an LED and a phototransistor within a single package. When current flows through the LED, it emits light that activates the phototransistor, allowing current to pass from collector to emitter. This method serves several purposes: level shifting, as the vehicle's battery voltage ranges from 12 to 14V necessitating a means to trigger a transistor; and electrical isolation, which mitigates the effects of electrical noise generated by the vehicle's alternator and other components. Power can be drawn directly from the vehicle to operate the NerdKit by connecting the vehicle's ground to the circuit ground and the battery voltage to the voltage regulator input. An additional large bypass capacitor (4.7µF) is incorporated to smooth out supply ripple and ensure stable operation. The source code for this project is available for download. It should be noted that the VPW protocol is particularly complex to implement, and much of the source code may not be applicable to projects utilizing different signaling protocols. This project exemplifies advanced microcontroller programming.

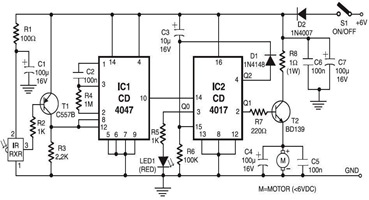

The described circuit utilizes the OBD-II protocol to interface with a vehicle's onboard diagnostics system. The NerdKits microcontroller kit is employed to capture data transmitted over the VPW protocol, which is specific to certain General Motors vehicles. The connection to the OBD-II port is made through a series of wires that link the microcontroller to the vehicle's data bus. The microcontroller interprets the signals received, allowing for real-time monitoring of various engine parameters.

To ensure compatibility with the vehicle's electrical system, an optocoupler is integrated into the design. This component provides electrical isolation, protecting the microcontroller from voltage spikes and noise generated by the vehicle's electrical system. The optocoupler's LED is connected to the vehicle's data line, while the phototransistor side interfaces with the microcontroller, allowing it to read the incoming signals without direct electrical contact.

The power supply for the microcontroller is derived from the vehicle's battery, which requires careful management to prevent damage. A voltage regulator is used to step down the battery voltage to a level suitable for the microcontroller. Additionally, a bypass capacitor is included in the circuit to filter out any high-frequency noise, ensuring stable operation of the microcontroller during data acquisition.

Safety precautions are paramount when working with automotive electronics. The circuit design should include fuses or circuit breakers to protect against overcurrent conditions. It is also advisable to use insulated tools and wear protective gear when handling electrical components in a vehicle environment.

In summary, this project showcases the integration of a microcontroller with a vehicle’s OBD-II system using the VPW protocol. It highlights the importance of electrical isolation, proper voltage management, and safety considerations in automotive electronics projects.Using the OBD-II (On Board Diagnostics) protocol, we can read live information from a car`s computer with our NerdKits microcontroller kit, as explained by our guest star, Elena T. , MIT class of 2011. This uses the port under your steering wheel to receive all kinds of information, and is used by auto mechanics for troubleshooting the "Check Engi

ne" light, and for periodic emissions tests with onboard sensors. In this microcontroller project, we implement the Variable Pulse Width (VPW) protocol, which is generally found on General Motors cars. Please note that if you attempt this project, your car may have a different signaling protocol, which would not be compatible with our code.

The car we used was a 1997 Chevy Cavalier. This was introduced soon after the 1996 law requiring US cars to have OBD-II buses, but there are not many sensors accessible from the data bus. On newer cars, you`d find oxygen sensors (allowing you to calculate MPG), but for our demo, we were able to measure: WARNING: Please note that by attempting this project, there are several risks to yourself and your property.

This project involves working in the presence of car battery voltage, which can supply dangerous amounts of current and cause fire or electrical damage. This project involves working with your car computer, and while manufacturers do their best to make them robust, it is possible to irreversibly damage your car`s computer or the vehicle itself.

And of course, if you`re the driver, you should be focusing on the road, and not some circuit and LCD on your dashboard. Optocouplers (or opto-isolators) provide a way to transmit information without creating a direct electrical connection.

In a single small chip package, they have an LED and phototransistor. Current passed through the LED side of the chip makes light, which hits the base of the phototransistor and allows current to flow through the collector to emitter. This may seem unnessary, but it is useful for a few reasons: Level shifting. The car`s battery voltage will be about 12-14V, and in order to pull the data bus high as the protocol requires, we need some way to trigger a transistor at this level.

Optical isolation means we don`t have to worry about the relative levels of our voltages, which would be a challenge here. Electrical isolation. The car`s battery voltage will be noisy thanks to an alternator that`s operating at variable RPM, a huge spike of current every time a cylinder needs to fire its spark plug, etc.

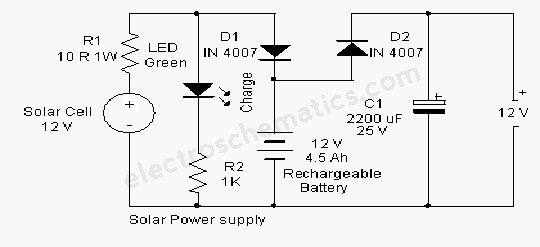

By optically coupling, we make it harder for electrical noise to disrupt our microcontroller`s proper operation. However, we found that it was fine to draw power directly from the car to power the NerdKit. To do this, we connected the car ground to our circuit ground, and the car battery voltage to the input of the voltage regulator.

We also added an extra large bypass capacitor (4. 7uF) to smooth the ripple on this supply and guarantee proper operation. You can download the source code here. Please note that the VPW protocol is a particularly "messy" one to implement, and that much of the source code here would not be applicable to a project with a different signaling protocol. This is a fairly advanced example of microcontroller programming. 🔗 External reference

The described circuit utilizes the OBD-II protocol to interface with a vehicle's onboard diagnostics system. The NerdKits microcontroller kit is employed to capture data transmitted over the VPW protocol, which is specific to certain General Motors vehicles. The connection to the OBD-II port is made through a series of wires that link the microcontroller to the vehicle's data bus. The microcontroller interprets the signals received, allowing for real-time monitoring of various engine parameters.

To ensure compatibility with the vehicle's electrical system, an optocoupler is integrated into the design. This component provides electrical isolation, protecting the microcontroller from voltage spikes and noise generated by the vehicle's electrical system. The optocoupler's LED is connected to the vehicle's data line, while the phototransistor side interfaces with the microcontroller, allowing it to read the incoming signals without direct electrical contact.

The power supply for the microcontroller is derived from the vehicle's battery, which requires careful management to prevent damage. A voltage regulator is used to step down the battery voltage to a level suitable for the microcontroller. Additionally, a bypass capacitor is included in the circuit to filter out any high-frequency noise, ensuring stable operation of the microcontroller during data acquisition.

Safety precautions are paramount when working with automotive electronics. The circuit design should include fuses or circuit breakers to protect against overcurrent conditions. It is also advisable to use insulated tools and wear protective gear when handling electrical components in a vehicle environment.

In summary, this project showcases the integration of a microcontroller with a vehicle’s OBD-II system using the VPW protocol. It highlights the importance of electrical isolation, proper voltage management, and safety considerations in automotive electronics projects.Using the OBD-II (On Board Diagnostics) protocol, we can read live information from a car`s computer with our NerdKits microcontroller kit, as explained by our guest star, Elena T. , MIT class of 2011. This uses the port under your steering wheel to receive all kinds of information, and is used by auto mechanics for troubleshooting the "Check Engi

ne" light, and for periodic emissions tests with onboard sensors. In this microcontroller project, we implement the Variable Pulse Width (VPW) protocol, which is generally found on General Motors cars. Please note that if you attempt this project, your car may have a different signaling protocol, which would not be compatible with our code.

The car we used was a 1997 Chevy Cavalier. This was introduced soon after the 1996 law requiring US cars to have OBD-II buses, but there are not many sensors accessible from the data bus. On newer cars, you`d find oxygen sensors (allowing you to calculate MPG), but for our demo, we were able to measure: WARNING: Please note that by attempting this project, there are several risks to yourself and your property.

This project involves working in the presence of car battery voltage, which can supply dangerous amounts of current and cause fire or electrical damage. This project involves working with your car computer, and while manufacturers do their best to make them robust, it is possible to irreversibly damage your car`s computer or the vehicle itself.

And of course, if you`re the driver, you should be focusing on the road, and not some circuit and LCD on your dashboard. Optocouplers (or opto-isolators) provide a way to transmit information without creating a direct electrical connection.

In a single small chip package, they have an LED and phototransistor. Current passed through the LED side of the chip makes light, which hits the base of the phototransistor and allows current to flow through the collector to emitter. This may seem unnessary, but it is useful for a few reasons: Level shifting. The car`s battery voltage will be about 12-14V, and in order to pull the data bus high as the protocol requires, we need some way to trigger a transistor at this level.

Optical isolation means we don`t have to worry about the relative levels of our voltages, which would be a challenge here. Electrical isolation. The car`s battery voltage will be noisy thanks to an alternator that`s operating at variable RPM, a huge spike of current every time a cylinder needs to fire its spark plug, etc.

By optically coupling, we make it harder for electrical noise to disrupt our microcontroller`s proper operation. However, we found that it was fine to draw power directly from the car to power the NerdKit. To do this, we connected the car ground to our circuit ground, and the car battery voltage to the input of the voltage regulator.

We also added an extra large bypass capacitor (4. 7uF) to smooth the ripple on this supply and guarantee proper operation. You can download the source code here. Please note that the VPW protocol is a particularly "messy" one to implement, and that much of the source code here would not be applicable to a project with a different signaling protocol. This is a fairly advanced example of microcontroller programming. 🔗 External reference