Electric shaver circuit

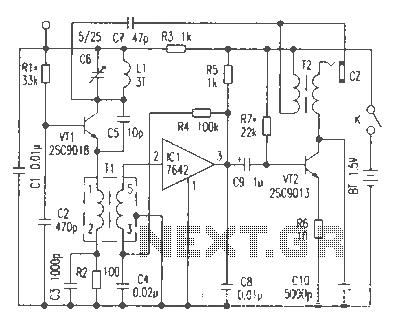

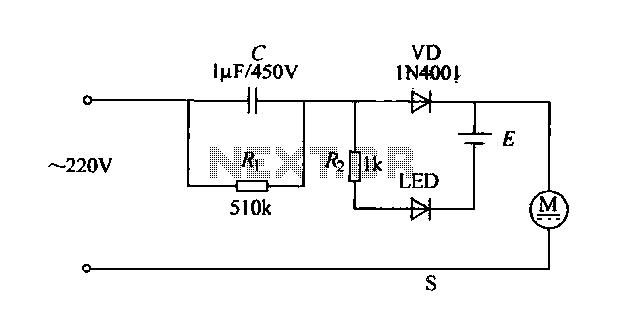

The electric shaver circuit is illustrated in Figure 1-17. It features a buck capacitor (C) rated at 1 µF and 450V, which connects through diode VD to charge 1.2V nickel-cadmium batteries. Additionally, after the buck converter, there is a display element in the form of an LED. When the shaver is not in use, it is connected to a 220V power charger. To operate the device, a toggle switch (S) is used to turn on the motor, which drives the rotational movement of the shaver head.

The electric shaver circuit operates by utilizing a buck converter topology to efficiently step down the voltage from the power supply. The buck capacitor (C) plays a crucial role in smoothing out the voltage and ensuring stable operation of the circuit. The diode (VD) is essential for allowing current to flow in one direction, thereby preventing backflow that could damage the circuit components, particularly when charging the nickel-cadmium batteries.

The integration of an LED display serves as a visual indicator of the shaver's operational status, enhancing user interaction. The LED illuminates when the device is powered on, providing a clear signal that the shaver is ready for use. The toggle switch (S) enables the user to easily control the power to the motor, which is responsible for the rotational motion necessary for effective shaving.

When the shaver is not in operation, it remains connected to a 220V power source for charging. This design choice ensures that the nickel-cadmium batteries are continuously charged and ready for use, promoting convenience and ensuring the device is always operational when needed. The motor, upon activation, engages the shaver head, allowing for efficient hair removal through its rotational motion. The overall circuit design emphasizes safety, efficiency, and user-friendliness, making it suitable for everyday grooming needs.Electric shavers thorn circuit shown in Figure 1-17. Shown by the capacitance C buck, buck capacitor C is lyF/450V, pass through the diode VD, to 1.2V nickel-cadmium batteries. After Buck Island for the display element to the LED. When not in use, connected to the 220V power charger, so when used, toggle switch S, and the motor is turned on, the motor drives the shaver piece rotation.

The electric shaver circuit operates by utilizing a buck converter topology to efficiently step down the voltage from the power supply. The buck capacitor (C) plays a crucial role in smoothing out the voltage and ensuring stable operation of the circuit. The diode (VD) is essential for allowing current to flow in one direction, thereby preventing backflow that could damage the circuit components, particularly when charging the nickel-cadmium batteries.

The integration of an LED display serves as a visual indicator of the shaver's operational status, enhancing user interaction. The LED illuminates when the device is powered on, providing a clear signal that the shaver is ready for use. The toggle switch (S) enables the user to easily control the power to the motor, which is responsible for the rotational motion necessary for effective shaving.

When the shaver is not in operation, it remains connected to a 220V power source for charging. This design choice ensures that the nickel-cadmium batteries are continuously charged and ready for use, promoting convenience and ensuring the device is always operational when needed. The motor, upon activation, engages the shaver head, allowing for efficient hair removal through its rotational motion. The overall circuit design emphasizes safety, efficiency, and user-friendliness, making it suitable for everyday grooming needs.Electric shavers thorn circuit shown in Figure 1-17. Shown by the capacitance C buck, buck capacitor C is lyF/450V, pass through the diode VD, to 1.2V nickel-cadmium batteries. After Buck Island for the display element to the LED. When not in use, connected to the 220V power charger, so when used, toggle switch S, and the motor is turned on, the motor drives the shaver piece rotation.