Over-temperature alarm and cooling circuit

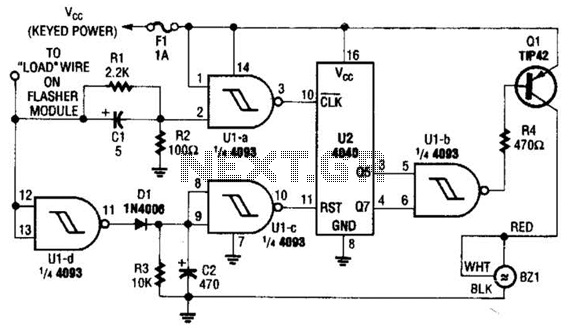

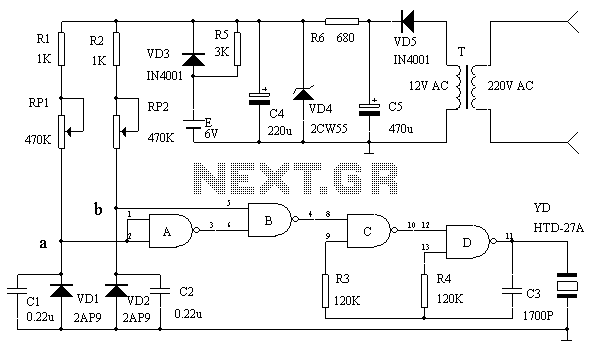

This circuit serves as an over-temperature alarm and cooling system utilizing CD4011 four NAND gate integrated circuits to monitor the oven's temperature. In the event of a thermostat circuit failure or power outage, if the internal temperature exceeds or falls below the permitted range, an alarm will sound to alert individuals to take appropriate action. The circuit has a resolution of 0.1 degrees. Diodes VD1 and VD2 are positioned within an incubator; when the internal temperature drops below the lower limit, the potential at point A becomes greater than the gate input threshold voltage U. Consequently, the output of gate A is low, causing the output of gate B to be high, which triggers a multivibrator circuit (comprising start-up gate D) to activate a piezoelectric alarm. Conversely, if the internal temperature rises above the upper limit, the potential at point B falls below the gate threshold voltage B U, resulting in a high output from gate B, thereby activating the piezoelectric alarm YD. The alarm will remain silent only when the internal temperature is within the specified limits. Potentiometers RP1 and RP2 allow for the adjustment of the lower and upper limits, respectively. The circuit is powered by both AC and DC sources, with E serving as a standby power supply during AC outages. When AC power is lost, diode VD3 conducts, enabling the backup power supply circuit. Given the low power consumption of the circuit, a compact battery backup solution is feasible. Additionally, to enhance anti-jamming capabilities, it is advisable to use shielded cables for the connections to sensors VD1 and VD2 if the wiring is excessively long. For proper adjustment of the incubation temperature, the following method is recommended: First, stabilize the incubator temperature at 36.5 degrees. Adjust the slide arm of potentiometer RP2 to its lowest position, then fine-tune the lower limit adjustment potentiometer RP1 until the alarm YD does not sound at this critical point. Next, set the incubator temperature to stabilize at 39.5 degrees and adjust potentiometer RP2 to ensure YD remains silent at this upper limit. Thus, when the incubator temperature drops below 36.5 degrees or exceeds 39.5 degrees, the alarm will activate, confirming the operational readiness of the oscillator.

The circuit design incorporates several key components, including the CD4011 NAND gates, which are configured to perform logic functions necessary for temperature monitoring and alarm activation. The diodes VD1 and VD2 serve as temperature sensors, converting thermal changes into voltage levels that can be interpreted by the NAND gates. The use of potentiometers RP1 and RP2 allows for precise calibration of the temperature thresholds, ensuring that the alarm system is responsive to the specific requirements of the application.

The power supply circuit is designed to seamlessly switch between AC and DC sources, providing reliability in various operating conditions. The inclusion of a backup power supply ensures that the system remains operational even during power outages, which is critical for applications such as incubators where temperature control is essential for the viability of eggs.

Furthermore, the use of shielded cables for sensor connections minimizes the risk of interference from external electromagnetic sources, enhancing the accuracy and reliability of the temperature readings. This attention to detail in the design ensures that the over-temperature alarm system functions effectively, providing timely alerts to prevent overheating or excessive cooling in the monitored environment.

Overall, this circuit represents a robust solution for temperature monitoring and alarm activation, suitable for a range of applications requiring precise thermal management.This is the over-temperature alarm and a cooling by the CD4011 four NAND gate integrated circuits, and for monitoring the temperature of the oven used. When the thermostat circuit failure or power outage, the inside temperature is above or below the allowed

range, it can sound an alarm to remind people to pay attention to take corresponding measures. The circuit has a resolving power of 0.1. Diodes VD1 and VD2 are placed in an incubator, when the inside temperature is lower than the lower limit, a figure greater than the potential of point A gate input threshold voltage U, A gate output is low, so that the door B output high level, then the door multivibrator C, consisting of start-up door D, the piezoelectric sheet sound the alarm; when the inside temperature is higher than the upper limit, b point potential is less than the gate threshold voltage B U, may be the door B output high, the piezoelectric sheet YD alarm. Only when the inside temperature is, the lower limit value between, YD will not audible. RP1 and RP2, respectively adjustment value may change the lower and upper limits respectively. AC and DC power supply circuit for the power supply, E is the standby power when AC power outage, VD3 conduction, backup power supply circuit, as the circuit consumes little, stacked battery backup power is available to reduce the volume.And sensors VD1, VD2 connected the wire is too long, it is best to use shielded cable, to enhance anti-jamming capability.Finally, chick incubation temperature monitoring to illustrate the adjustment method: First, the incubator temperature adjustment stable at 36.5, and the slide arm RP2 moved to the lowermost end, then the lower limit adjustment potentiometer RP1 adjusted so YD does not ring loud and critical place; then turn the incubator temperature regulator stable at 39.5, the upper limit was adjusted to make the adjustment potentiometer RP2 YD does not ring loud and critical place.

Thus, when the incubator temperature below 36.5 or higher than 39.5, an alarm will sound, the oscillator can officially use.

The circuit design incorporates several key components, including the CD4011 NAND gates, which are configured to perform logic functions necessary for temperature monitoring and alarm activation. The diodes VD1 and VD2 serve as temperature sensors, converting thermal changes into voltage levels that can be interpreted by the NAND gates. The use of potentiometers RP1 and RP2 allows for precise calibration of the temperature thresholds, ensuring that the alarm system is responsive to the specific requirements of the application.

The power supply circuit is designed to seamlessly switch between AC and DC sources, providing reliability in various operating conditions. The inclusion of a backup power supply ensures that the system remains operational even during power outages, which is critical for applications such as incubators where temperature control is essential for the viability of eggs.

Furthermore, the use of shielded cables for sensor connections minimizes the risk of interference from external electromagnetic sources, enhancing the accuracy and reliability of the temperature readings. This attention to detail in the design ensures that the over-temperature alarm system functions effectively, providing timely alerts to prevent overheating or excessive cooling in the monitored environment.

Overall, this circuit represents a robust solution for temperature monitoring and alarm activation, suitable for a range of applications requiring precise thermal management.This is the over-temperature alarm and a cooling by the CD4011 four NAND gate integrated circuits, and for monitoring the temperature of the oven used. When the thermostat circuit failure or power outage, the inside temperature is above or below the allowed

range, it can sound an alarm to remind people to pay attention to take corresponding measures. The circuit has a resolving power of 0.1. Diodes VD1 and VD2 are placed in an incubator, when the inside temperature is lower than the lower limit, a figure greater than the potential of point A gate input threshold voltage U, A gate output is low, so that the door B output high level, then the door multivibrator C, consisting of start-up door D, the piezoelectric sheet sound the alarm; when the inside temperature is higher than the upper limit, b point potential is less than the gate threshold voltage B U, may be the door B output high, the piezoelectric sheet YD alarm. Only when the inside temperature is, the lower limit value between, YD will not audible. RP1 and RP2, respectively adjustment value may change the lower and upper limits respectively. AC and DC power supply circuit for the power supply, E is the standby power when AC power outage, VD3 conduction, backup power supply circuit, as the circuit consumes little, stacked battery backup power is available to reduce the volume.And sensors VD1, VD2 connected the wire is too long, it is best to use shielded cable, to enhance anti-jamming capability.Finally, chick incubation temperature monitoring to illustrate the adjustment method: First, the incubator temperature adjustment stable at 36.5, and the slide arm RP2 moved to the lowermost end, then the lower limit adjustment potentiometer RP1 adjusted so YD does not ring loud and critical place; then turn the incubator temperature regulator stable at 39.5, the upper limit was adjusted to make the adjustment potentiometer RP2 YD does not ring loud and critical place.

Thus, when the incubator temperature below 36.5 or higher than 39.5, an alarm will sound, the oscillator can officially use.