Parallel Path Magnet Motor

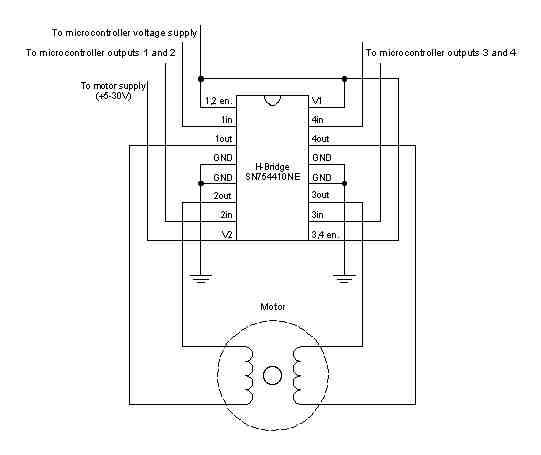

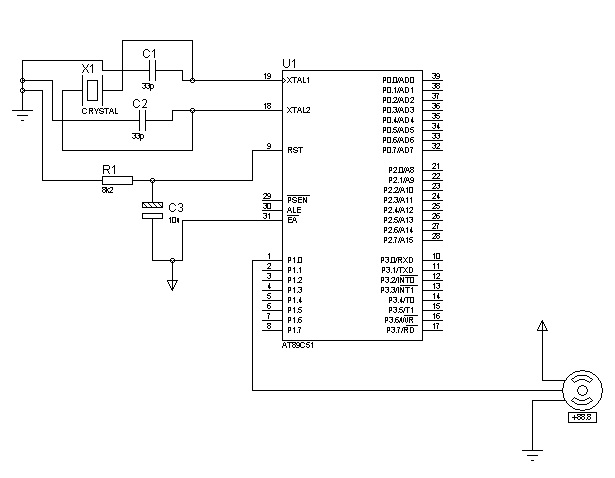

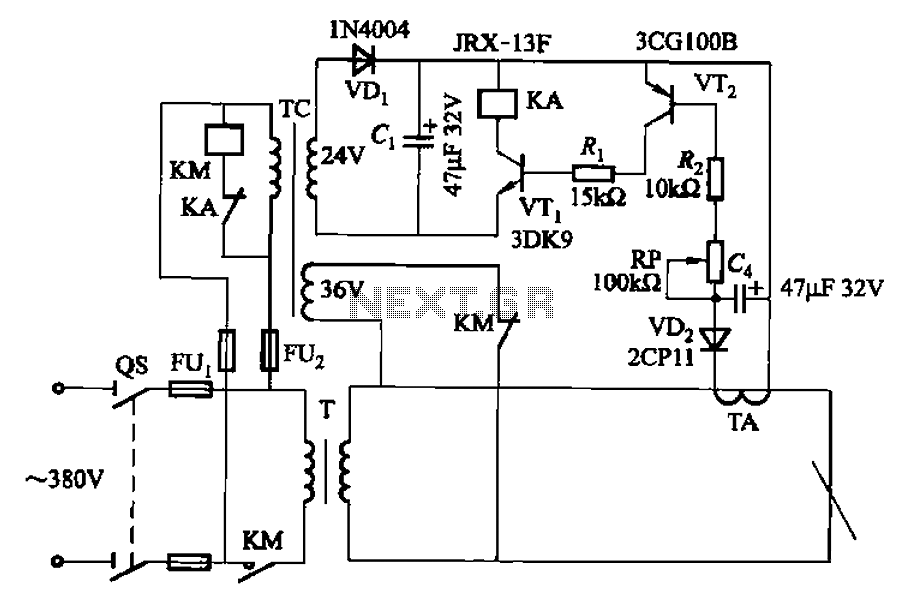

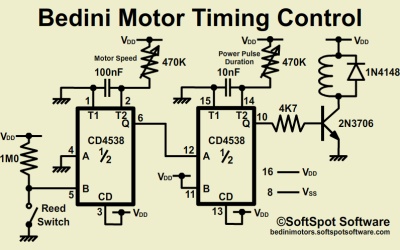

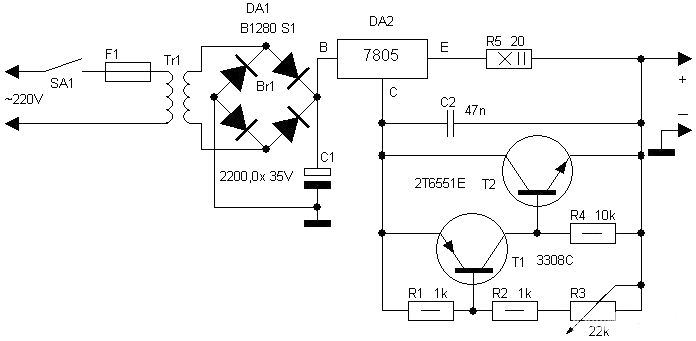

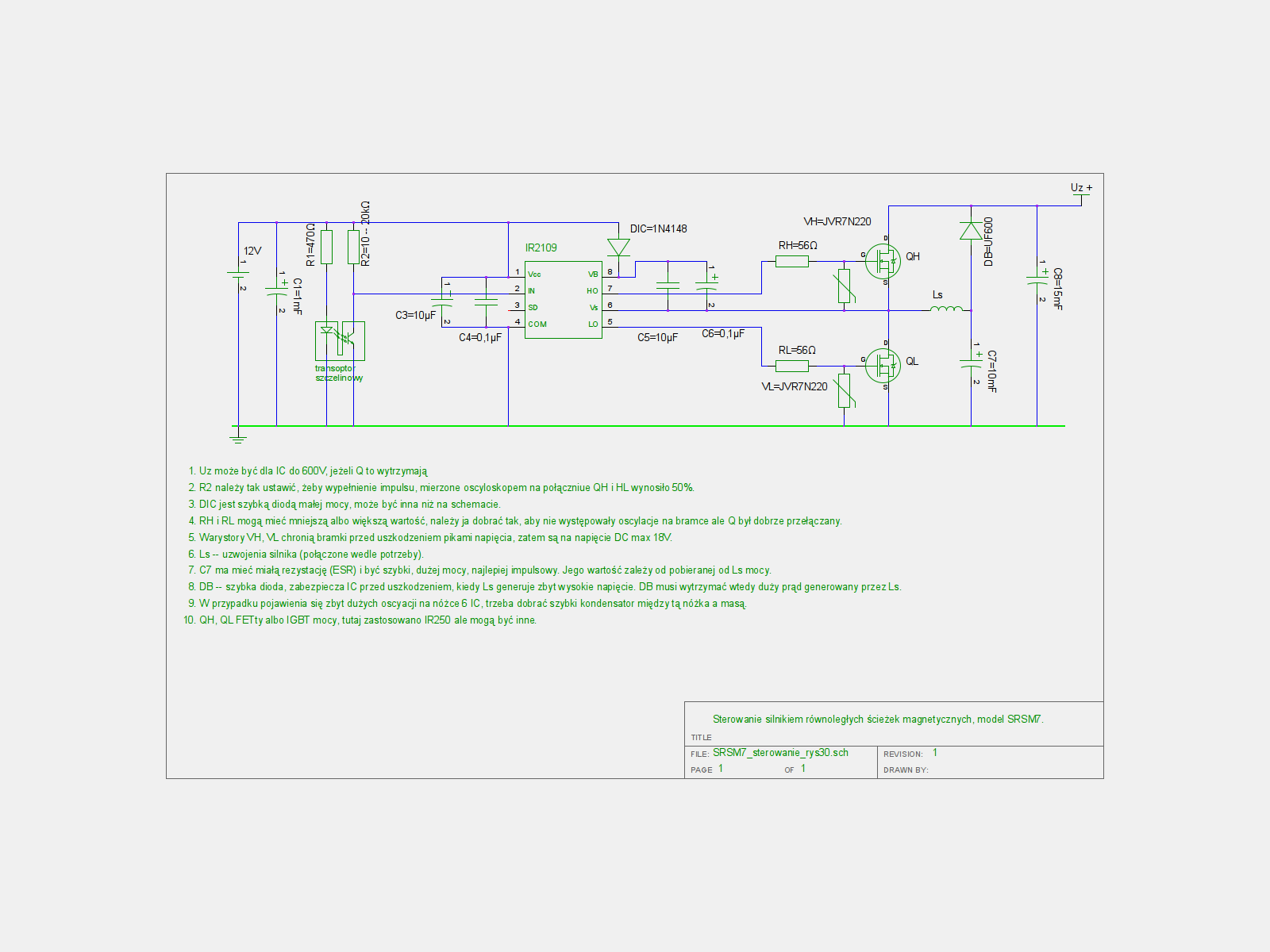

Previously, one magnet measured 2x2x3 cm; it has now been replaced with a round magnet measuring 1.5 x 2 cm. This change significantly impacts the motor's operation, allowing it to run on 1 V and 0.1 A, resulting in a power consumption of 0.1 W. There is a wealth of information available that can expedite project timelines, as two university students have conducted extensive research and development on this topic and hold a new patent. However, the entire project is open for public access. The discussion thread is in Italian, and online translation tools may be utilized for assistance. A thorough review of the translated text did not yield any patent documentation, schematics, or other technical information relevant to further experimentation. The ongoing research focuses on the Parallel Path Magnet Motor (PPMM) version 7, which incorporates ferrite magnets as previously suggested. These ferrite magnets are less powerful than the earlier neodymium magnets but maintain the same dimensions. The Parallel Path Magnet Motor SRSM7 version 7 is designed for a nominal power output of approximately 1 kW, with operational testing ranging from 0.7 V to 30 V, beginning with a power draw of 0.15 W. This version differs from its predecessors by utilizing ferrite magnets instead of neodymium. The input configuration is designed for the entire system to consume 30 W, with the energy recovery subsystem accounting for 27 W, meaning the motor itself effectively uses only 3 W.

The Parallel Path Magnet Motor (PPMM) SRSM7 version 7 represents a significant evolution in motor design, particularly through the integration of ferrite magnets. The reduction in size from a rectangular to a cylindrical magnet not only optimizes spatial efficiency but also alters the magnetic field dynamics, which can enhance performance characteristics at lower voltages. The ability to operate at a mere 1 V and 0.1 A indicates a highly efficient design that minimizes energy consumption while maintaining functional output.

The motor's nominal power rating of approximately 1 kW suggests that it is capable of handling substantial loads, making it suitable for various applications. The operational range of 0.7 V to 30 V allows for flexibility in different environments, accommodating various power supply conditions. The initial power draw of 0.15 W at startup is indicative of a low-energy requirement for activation, which is advantageous for applications where energy conservation is critical.

The design's energy recovery subsystem, which consumes 27 W, plays a crucial role in enhancing overall efficiency by reclaiming energy that would otherwise be lost during operation. This feature allows the motor to maintain a manageable power consumption of only 3 W during typical operation, highlighting its potential for sustainable energy applications.

Further exploration of this technology may benefit from detailed schematics and technical documentation, which would provide insights into the specific configurations and electrical characteristics of the motor. The absence of such information in the current resources suggests an opportunity for additional research and development, particularly in optimizing the efficiency and performance of the ferrite magnets in the PPMM design. Continued investigation into the underlying principles of this motor design could lead to innovative applications and advancements in the field of electric motor technology.Before one magnet was 2x2x3 cm, now it is a round one 1. 5 x 2 cm only. This makes a huge difference, the motor can be run on1 V and 0. 1 A that makes 0. 1 W. you will find a lot of info, and cut time on your project, these two university students have done a lot of R and D on it, plus they have a new patent on it, yes a new patent but the all thing is open book, the tread is in Italian, use any of the web translator, i hope this helps you out Thank you. I did, a few weeks ago, went through the entire text with translation to English. But I didn`t find any patent file. Also I didn`t find schematic or other technical info that I can use to progress in my experiments. Maybe I missed it Continuing my research with PPMM (Parallel Path Magnet Motor) version 7. The difference is that this motor has ferrite magnets, as you suggested. They are much weaker compared to the previous ones, neodymium, but same dimensions. Parallel path magnet motor SRSM7 version 7 of nominal ~ 1 kW power - a test how it works from 0. 7 V to 30 V, when drawing power starting from 0. 15 W. This version differs from the previous ones with magnets, now ferrite magnets are used, not neodymium ones. Parallel path magnet motor version SRSM7. The input is set up so as the entire system consumes 30 W. The energy recovery subsystem consumes 27 W, so the motor itself practically is using only 3 W. 🔗 External reference

The Parallel Path Magnet Motor (PPMM) SRSM7 version 7 represents a significant evolution in motor design, particularly through the integration of ferrite magnets. The reduction in size from a rectangular to a cylindrical magnet not only optimizes spatial efficiency but also alters the magnetic field dynamics, which can enhance performance characteristics at lower voltages. The ability to operate at a mere 1 V and 0.1 A indicates a highly efficient design that minimizes energy consumption while maintaining functional output.

The motor's nominal power rating of approximately 1 kW suggests that it is capable of handling substantial loads, making it suitable for various applications. The operational range of 0.7 V to 30 V allows for flexibility in different environments, accommodating various power supply conditions. The initial power draw of 0.15 W at startup is indicative of a low-energy requirement for activation, which is advantageous for applications where energy conservation is critical.

The design's energy recovery subsystem, which consumes 27 W, plays a crucial role in enhancing overall efficiency by reclaiming energy that would otherwise be lost during operation. This feature allows the motor to maintain a manageable power consumption of only 3 W during typical operation, highlighting its potential for sustainable energy applications.

Further exploration of this technology may benefit from detailed schematics and technical documentation, which would provide insights into the specific configurations and electrical characteristics of the motor. The absence of such information in the current resources suggests an opportunity for additional research and development, particularly in optimizing the efficiency and performance of the ferrite magnets in the PPMM design. Continued investigation into the underlying principles of this motor design could lead to innovative applications and advancements in the field of electric motor technology.Before one magnet was 2x2x3 cm, now it is a round one 1. 5 x 2 cm only. This makes a huge difference, the motor can be run on1 V and 0. 1 A that makes 0. 1 W. you will find a lot of info, and cut time on your project, these two university students have done a lot of R and D on it, plus they have a new patent on it, yes a new patent but the all thing is open book, the tread is in Italian, use any of the web translator, i hope this helps you out Thank you. I did, a few weeks ago, went through the entire text with translation to English. But I didn`t find any patent file. Also I didn`t find schematic or other technical info that I can use to progress in my experiments. Maybe I missed it Continuing my research with PPMM (Parallel Path Magnet Motor) version 7. The difference is that this motor has ferrite magnets, as you suggested. They are much weaker compared to the previous ones, neodymium, but same dimensions. Parallel path magnet motor SRSM7 version 7 of nominal ~ 1 kW power - a test how it works from 0. 7 V to 30 V, when drawing power starting from 0. 15 W. This version differs from the previous ones with magnets, now ferrite magnets are used, not neodymium ones. Parallel path magnet motor version SRSM7. The input is set up so as the entire system consumes 30 W. The energy recovery subsystem consumes 27 W, so the motor itself practically is using only 3 W. 🔗 External reference