Replacing Motorola Batteries

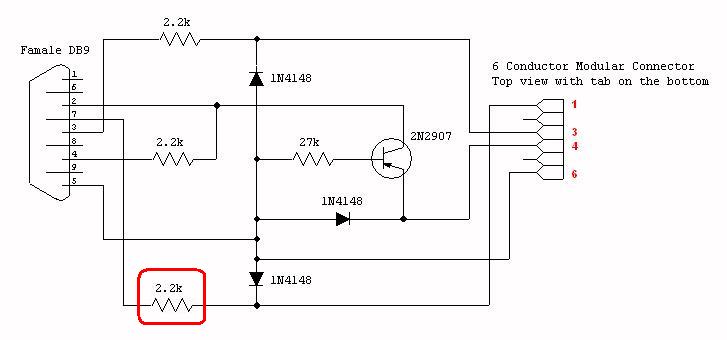

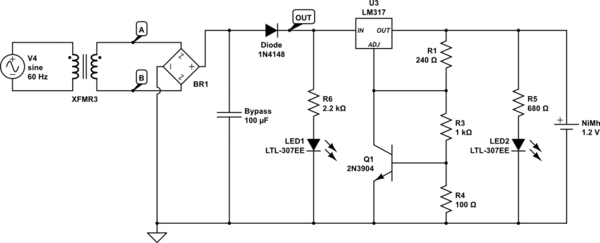

The battery packs were approximately $60 per pair, including a charger and batteries, and feature a three-bar battery gauge. Through experimentation, it was found that a voltage greater than 4.28V activates all three bars, while a voltage above 3.47V activates two bars. Below this latter voltage, the radio emits a chirping sound regularly, and only one bar lights up. After several years of use, it was observed that the batteries do not last longer than a few hours, prompting the need for replacement. A web search indicated that replacement battery packs cost around $12 each (plus shipping) and have a capacity of only 600mAh. Consequently, a homebrew battery replacement was investigated. Upon peeling back the sticker on one battery pack, it was discovered that the underlying electronics are quite simple and can be easily replicated. One terminal of the charger connects to the negative terminal of the battery pack, while the other connects to the positive terminal through a blocking diode. Inserting the three batteries into the radio and verifying power is essential; if it does not power up, metal tabs may need to be bent to meet the battery terminals. The paper backing on the tape should be removed, and a tab should be folded to form a 'b' shape, with the top arm non-sticky and the bottom arm sticky. The bottom part should be taped onto a corner of the paper substrate, with the non-sticky top arm sticking out. This arm should be inserted under the negative terminal of the battery, ensuring both sides of this leg are exposed copper for good contact with the battery and radio terminal. A 0.75" square piece of copper tape should be taped in the opposite corner of the paper to create charging contacts for the new pack. The leg of this 'P' should be inserted under the positive terminal of the rightmost battery (non-sticky) and glued to the paper substrate. The diode should be soldered to the two copper tabs, with the cathode ring oriented toward the positive battery terminal. The diode should be positioned in the gap between the two batteries. The original battery packs are 600mAh units, while the new ones, using NiMH technology, have more than three times the capacity and should last several days between recharges with daily use. It is important to recycle used batteries due to their cadmium content. After some usage, it became evident that the charging circuitry required modification to provide a higher charge current. By tracing the circuit, a schematic was developed, which involved shorting R3 and R6 with a jumper and replacing R2 and R5 with a 10 Ohm resistor. This modification quadruples the charging current from the standard 39mA to 155mA (both measured), remaining below the C/10 slow charge rate, thus ensuring safety for extended charging periods.

The described battery replacement and charging circuit modifications are critical for enhancing the performance and longevity of the radio device. The implementation of a homebrew battery pack using NiMH cells significantly increases the capacity, allowing for extended use between charges. The approach involves careful assembly of the battery pack with attention to the orientation and connections of the terminals, ensuring reliable contact points for the charger. The addition of the blocking diode is crucial in preventing reverse current flow, which could damage the battery or the device.

To facilitate the charging process, the modifications to the charger circuitry involve specific resistor adjustments that directly impact the current flowing to the batteries. By replacing R2 and R5 with a lower resistance value, the charging current is increased, thereby reducing the total charging time and improving efficiency. This change is particularly beneficial in applications requiring frequent battery replacements, as it allows for quicker turnaround times while maintaining safety standards.

In summary, the combination of a homemade battery pack and optimized charging circuitry provides a practical solution for extending the operational life of the radio device, demonstrating effective engineering practices in battery management and circuit design.These were about $60 a pair with charger and batteries, and have a three-bar battery gauge. With experimentation I found that if the voltage is greater than 4. 28V, all three bars light up. More than 3. 47V, two bars will light up. Below this latter voltage the radio chirps regularly, and only one bar will light up. After a few years use, we noticed the batteries do not last longer than a few hours, so I wanted to replace them. A search on the web shows that the battery packs are about $12 each (plus shipping), and their capacity is still only 600mAh, so I decided to investigate a home-brew battery replacement for these units. I pealed back the sticker on one battery pack and discovered that the hidden elecronics are very simple and can be easily reproduced.

One terminal of the charger connections connects to the negative terminal of the battery pack, and the other terminal connects to the positive terminal via a blocking diode. Insert the three batteries into the radio, and verify that it powers up. If it doesn`t you may have to bend the metal tabs out to meet the battery terminals. Remove the paper backing, on the tape, and fold the tab over so that the tape forms a `b` shape. The top arm of the `b` is not sticky on either side because you folded the tab over. The bottom belly of the `b` is sticky. Tape the bottom (belly) part of the `b` onto a corner of the paper substrate (top copper tab in the pictures below).

Have the non-sticky top arm stick out of the edge. Insert the top arm of the `b` under the negative terminal of the battery. Since you folded the tab under, both sides of this leg are exposed copper and will make good contact with the battery and the radio terminal. Tape the 0. 75" square piece of copper tape in the opposite corner of the paper (see below). The two previous squares now form the charging contacts for the new pack. Insert the leg of this `P` under the positive terminal of the right most battery (not sticky), and glue the exposed tape onto the paper substrate (bottom picture).

Solder the diode to the latter two copper tabs. Cathode ring toward the positive battery terminal as shown in the bottom picture. Put the diode in the crease formed by the gap between the two batteries. The original battery packs are only 600mAh units. The new ones are more than three times the capacity (I used NiMH), and should last us a few days between recharging with even daily use. Remember to recycle your used batteries as they contain Cadmium. After some use it became clear that the circuitry in the charger needed to be modified to provide more charge current for the batteries.

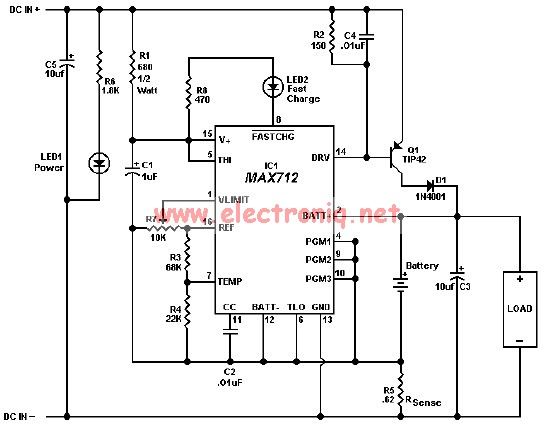

Tracing the circuit, I came up with this schematic. To increase the charging current, I shorted R3 and R6 with a jumper and replaced R2 and R5 with a 10 Ohm resistor. This quadruples the charging current from the standard 39mA to 155mA (both measured). It is still below the C/10 slow charge rate, so it should be safe to leave the radios charging for extended periods.

🔗 External reference

The described battery replacement and charging circuit modifications are critical for enhancing the performance and longevity of the radio device. The implementation of a homebrew battery pack using NiMH cells significantly increases the capacity, allowing for extended use between charges. The approach involves careful assembly of the battery pack with attention to the orientation and connections of the terminals, ensuring reliable contact points for the charger. The addition of the blocking diode is crucial in preventing reverse current flow, which could damage the battery or the device.

To facilitate the charging process, the modifications to the charger circuitry involve specific resistor adjustments that directly impact the current flowing to the batteries. By replacing R2 and R5 with a lower resistance value, the charging current is increased, thereby reducing the total charging time and improving efficiency. This change is particularly beneficial in applications requiring frequent battery replacements, as it allows for quicker turnaround times while maintaining safety standards.

In summary, the combination of a homemade battery pack and optimized charging circuitry provides a practical solution for extending the operational life of the radio device, demonstrating effective engineering practices in battery management and circuit design.These were about $60 a pair with charger and batteries, and have a three-bar battery gauge. With experimentation I found that if the voltage is greater than 4. 28V, all three bars light up. More than 3. 47V, two bars will light up. Below this latter voltage the radio chirps regularly, and only one bar will light up. After a few years use, we noticed the batteries do not last longer than a few hours, so I wanted to replace them. A search on the web shows that the battery packs are about $12 each (plus shipping), and their capacity is still only 600mAh, so I decided to investigate a home-brew battery replacement for these units. I pealed back the sticker on one battery pack and discovered that the hidden elecronics are very simple and can be easily reproduced.

One terminal of the charger connections connects to the negative terminal of the battery pack, and the other terminal connects to the positive terminal via a blocking diode. Insert the three batteries into the radio, and verify that it powers up. If it doesn`t you may have to bend the metal tabs out to meet the battery terminals. Remove the paper backing, on the tape, and fold the tab over so that the tape forms a `b` shape. The top arm of the `b` is not sticky on either side because you folded the tab over. The bottom belly of the `b` is sticky. Tape the bottom (belly) part of the `b` onto a corner of the paper substrate (top copper tab in the pictures below).

Have the non-sticky top arm stick out of the edge. Insert the top arm of the `b` under the negative terminal of the battery. Since you folded the tab under, both sides of this leg are exposed copper and will make good contact with the battery and the radio terminal. Tape the 0. 75" square piece of copper tape in the opposite corner of the paper (see below). The two previous squares now form the charging contacts for the new pack. Insert the leg of this `P` under the positive terminal of the right most battery (not sticky), and glue the exposed tape onto the paper substrate (bottom picture).

Solder the diode to the latter two copper tabs. Cathode ring toward the positive battery terminal as shown in the bottom picture. Put the diode in the crease formed by the gap between the two batteries. The original battery packs are only 600mAh units. The new ones are more than three times the capacity (I used NiMH), and should last us a few days between recharging with even daily use. Remember to recycle your used batteries as they contain Cadmium. After some use it became clear that the circuitry in the charger needed to be modified to provide more charge current for the batteries.

Tracing the circuit, I came up with this schematic. To increase the charging current, I shorted R3 and R6 with a jumper and replaced R2 and R5 with a 10 Ohm resistor. This quadruples the charging current from the standard 39mA to 155mA (both measured). It is still below the C/10 slow charge rate, so it should be safe to leave the radios charging for extended periods.

🔗 External reference