robotics reflow controller

Introduction to the Reflow Process and PID Controller Circuit Documentation. This document discusses the benefits of using Surface Mount Devices (SMD) in circuit design, highlighting advantages such as reduced size and cost compared to traditional through-hole components.

The reflow soldering process is a critical technique in electronics manufacturing, particularly for assemblies that utilize SMD components. This process involves applying solder paste to the pads of a printed circuit board (PCB) where SMD components will be placed. After placement, the assembly undergoes a heating phase, which allows the solder to melt and form reliable electrical connections.

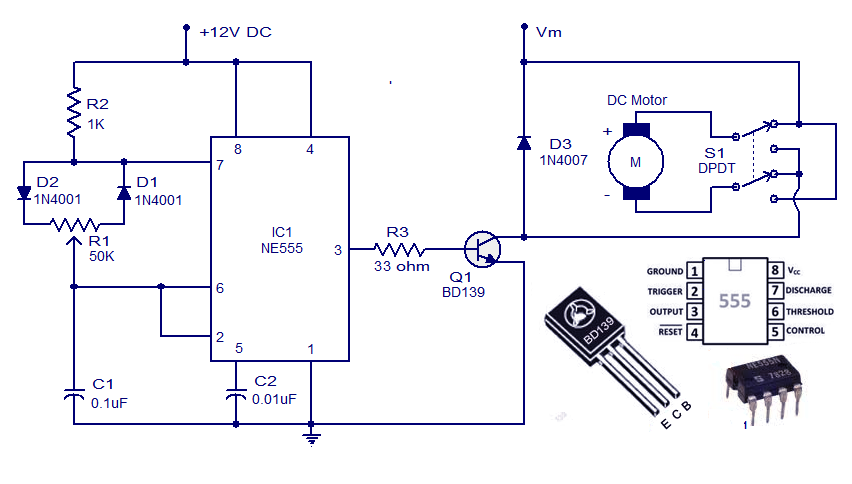

A Proportional-Integral-Derivative (PID) controller is often integrated into the reflow process to maintain precise temperature profiles throughout the heating cycle. The PID controller continuously monitors the temperature and adjusts the heating elements to ensure that the solder reaches the optimal melting point without overheating, which could damage components or the PCB itself.

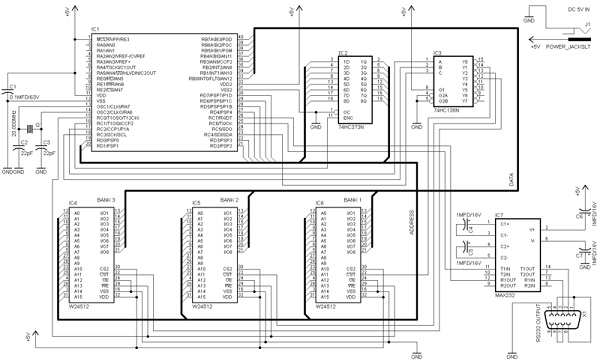

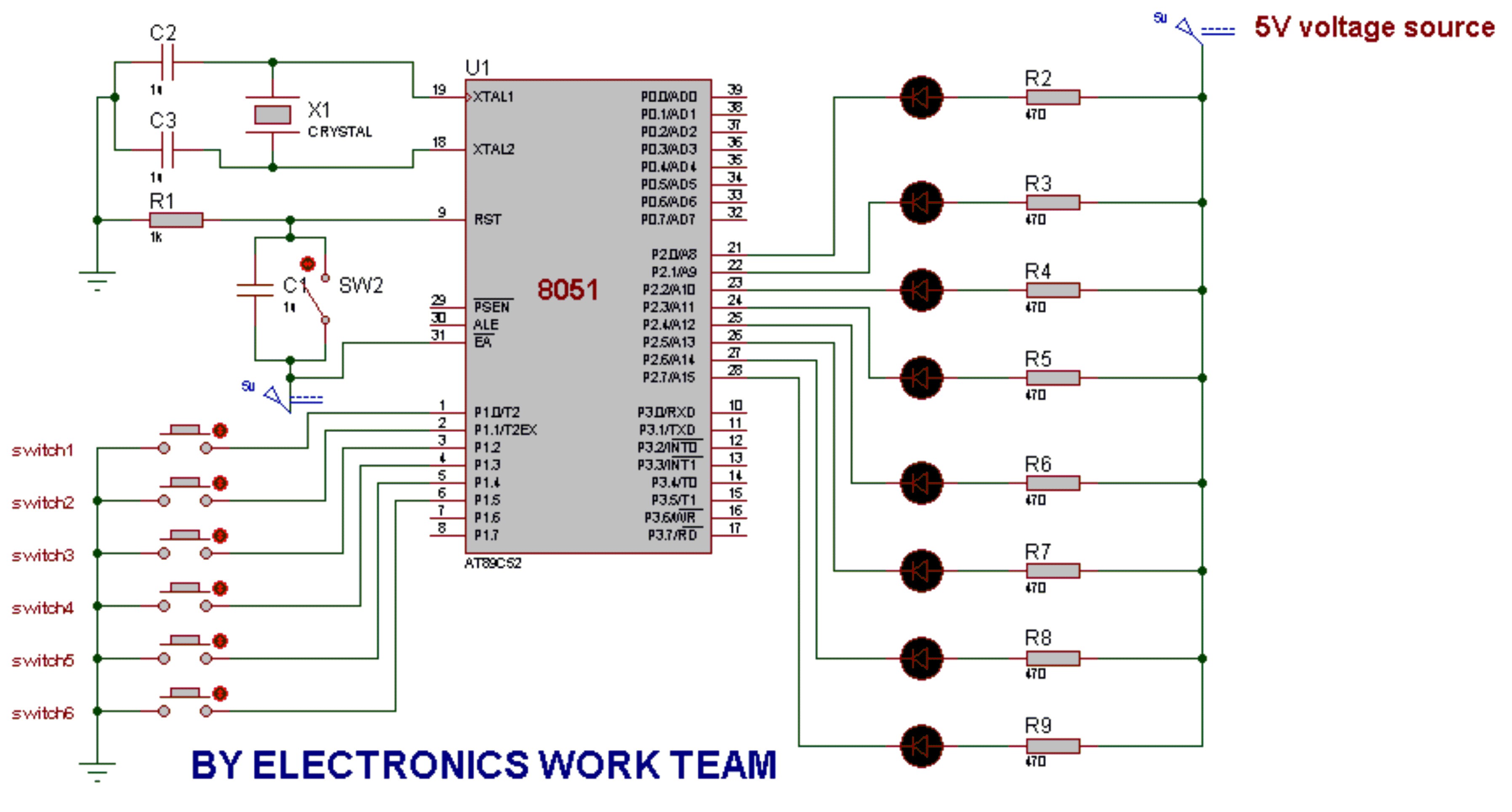

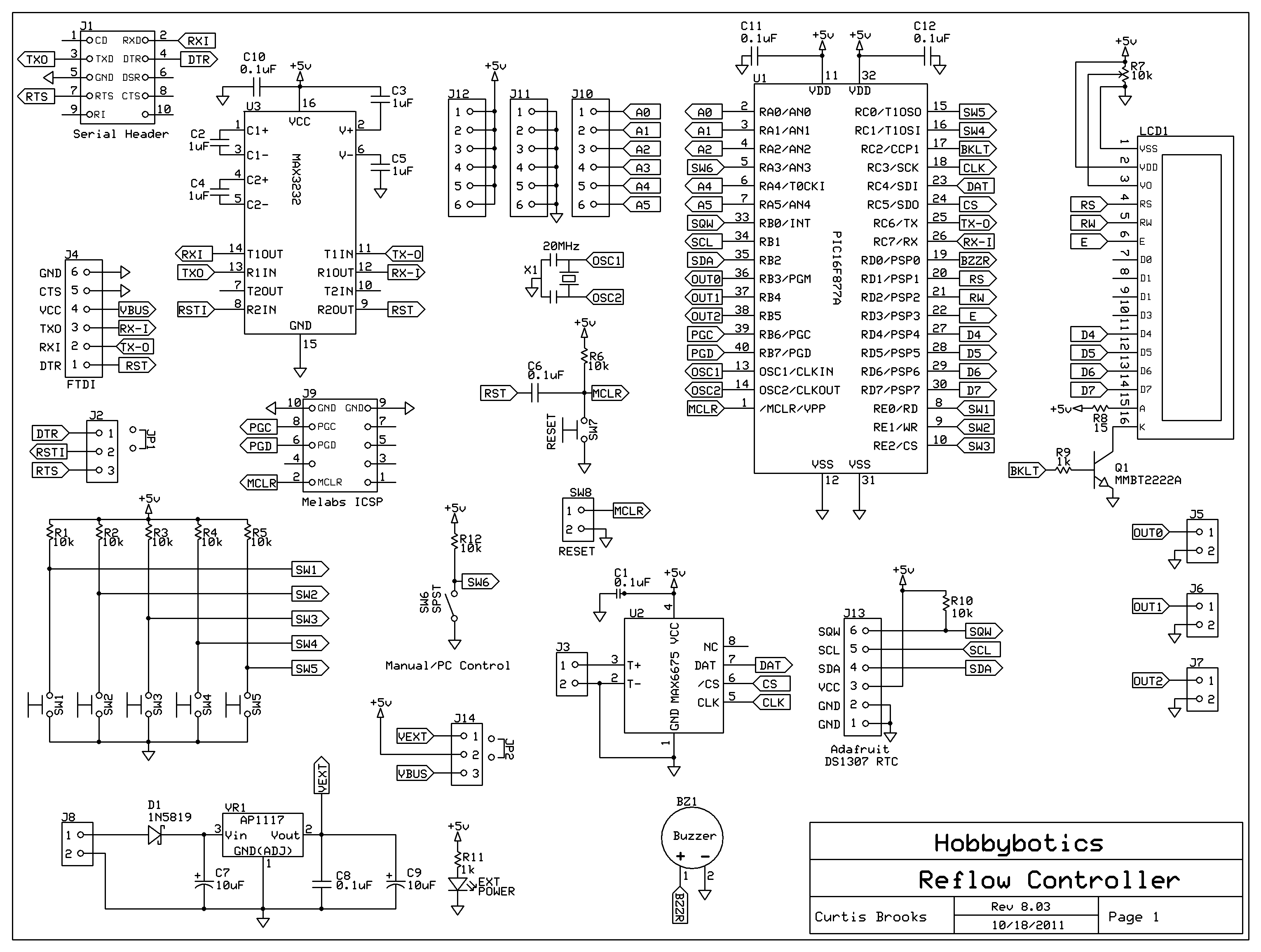

The documentation for building a PID controller circuit for a reflow oven typically includes schematics, component lists, and firmware instructions. The schematic should clearly outline the connections between the microcontroller, temperature sensors, and heating elements. Additionally, the firmware must be programmed to implement the PID control algorithm, which requires tuning of the proportional, integral, and derivative parameters to achieve the desired response.

In conclusion, the integration of SMD components and the implementation of a PID controller in the reflow process significantly enhance the efficiency and reliability of electronic assemblies. Understanding these concepts is essential for modern electronics design and manufacturing.Introduction The Reflow Process What is PID Controller Circuit Documentation Build It Firmware Software Conclusion Related Links References Disclaimer Introduction A while ago I decided to start designing my circuits using Surface Mount Devices (SMD). There are many advantages to using SMD components over through-hole components. Some of the major advantages are size and cost.. 🔗 External reference

The reflow soldering process is a critical technique in electronics manufacturing, particularly for assemblies that utilize SMD components. This process involves applying solder paste to the pads of a printed circuit board (PCB) where SMD components will be placed. After placement, the assembly undergoes a heating phase, which allows the solder to melt and form reliable electrical connections.

A Proportional-Integral-Derivative (PID) controller is often integrated into the reflow process to maintain precise temperature profiles throughout the heating cycle. The PID controller continuously monitors the temperature and adjusts the heating elements to ensure that the solder reaches the optimal melting point without overheating, which could damage components or the PCB itself.

The documentation for building a PID controller circuit for a reflow oven typically includes schematics, component lists, and firmware instructions. The schematic should clearly outline the connections between the microcontroller, temperature sensors, and heating elements. Additionally, the firmware must be programmed to implement the PID control algorithm, which requires tuning of the proportional, integral, and derivative parameters to achieve the desired response.

In conclusion, the integration of SMD components and the implementation of a PID controller in the reflow process significantly enhance the efficiency and reliability of electronic assemblies. Understanding these concepts is essential for modern electronics design and manufacturing.Introduction The Reflow Process What is PID Controller Circuit Documentation Build It Firmware Software Conclusion Related Links References Disclaimer Introduction A while ago I decided to start designing my circuits using Surface Mount Devices (SMD). There are many advantages to using SMD components over through-hole components. Some of the major advantages are size and cost.. 🔗 External reference