schematics Buck switching regulator based on ATtiny84a -- please critique!

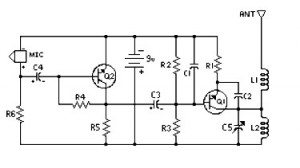

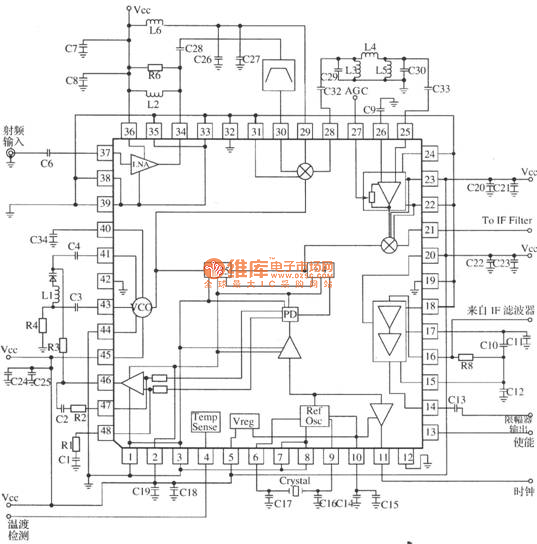

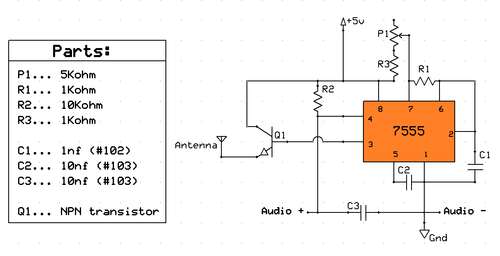

The microcontroller will not be able to drive the gate of Q1 effectively, as GPIO pins typically can only source a few milliamps, resulting in slow turn-on and turn-off times. This limitation will affect the performance of the high-side switch. Additionally, the absence of a gate-to-source resistor on Q1 means that the operation of the MOSFET relies entirely on the GPIO state. If the GPIO pin enters a high-impedance state, the MOSFET may unintentionally turn on due to environmental charge accumulation, which could lead to excessive power consumption since the drain will be high, as the input is nearly equal to the output. The approximately 225mA that will flow through Q1 could cause overheating, as it is a relatively small component. The purely resistive feedback network is inadequate; compensation and/or filtering are necessary. The comparator used may respond too quickly to switching noise, ripple, or other disturbances. The design lacks an error amplifier with compensation to regulate gain and phase, necessitating a capacitor across R5 for stability. Furthermore, the circuit does not include reverse-polarity protection or an input fuse, which is critical, especially in battery-operated systems due to the risk of short circuits. The schematic is incomplete and lacks essential safety features required for high-power applications. The main challenge in this design is managing high current levels. The power processing components, power modulator, and filtering must be closely examined. The power FET is a P-channel type, specifically the IRF4905, with a Rdson of 0.02 at 25°C and 0.034 at 150°C, resulting in significant conduction losses. For an input voltage of 16.8V, output voltage of 12V, and a current of 40A, the conduction loss is calculated as Pcond = D * Iout² * Rdson = (0.7)(1600)(0.034) = 38W. Considering the thermal resistance of the TO220 package and the heat sink junction, a heat sink with a thermal resistance of 2°C/W is necessary to maintain a junction temperature of 150°C at an ambient temperature of 25°C. It is advisable to use N-channel FETs in high-current applications, as they typically exhibit one-third the Rdson of P-channel FETs. The gate drive in this design is inadequate, particularly for turn-off, as a 70-ohm resistor will result in a turn-off time of at least 500ns for a FET with a Ciss of 3500pF, leading to significant switching losses, estimated at around 15W. Therefore, enhancing the gate drive is crucial, and transitioning to an N-channel switching FET paired with a synchronous rectifier and a suitable gate drive IC (such as the IR2104 or LM5104) would be beneficial. While hysteretic control can work effectively with constant on-time and variable off-time, the design's use of a microcontroller's comparator poses challenges. Access to the comparator is necessary to implement additional hysteresis, requiring a comparator with hysteresis and a response time of less than 500ns, ideally with about 100mV of hysteresis. The output filter design includes a good inductor, L1, which may approach saturation at 40A plus ripple current, though this is not a major concern. The output capacitors, C1 and C2, are ceramic, which is a suitable choice, allowing for a total ESR of less than 20 mOhms for a ripple voltage of approximately 100mV. Notably, the load resistance at maximum load (~0.3 Ohms) is close to the characteristic impedance of the output filter (~0.2 Ohms), indicating a well-damped filter. If the supply is intended solely for motor operation, this characteristic is advantageous.

The circuit design requires significant improvements in several areas to ensure reliable operation under high-current conditions. To enhance the gate drive, implementing a dedicated gate driver IC that can provide sufficient current to quickly charge and discharge the gate capacitance of the MOSFET is essential. This will minimize switching losses and improve overall efficiency. Transitioning to an N-channel MOSFET will also reduce conduction losses due to its lower Rdson.

Incorporating proper thermal management is crucial, especially considering the high power levels involved. This includes selecting appropriate heat sinks and ensuring adequate airflow around the components.

For the feedback network, using a combination of resistive and capacitive elements will help stabilize the control loop and mitigate the effects of noise and ripple. The addition of an error amplifier with compensation will enhance the performance of the comparator, allowing for better control of the output voltage and improved transient response.

The output filter design should also be revisited to ensure that it can handle the expected ripple current without saturating. Selecting an inductor with a higher current rating and ensuring that the capacitors are rated for the appropriate voltage and ripple current will enhance reliability.

Overall, addressing these design considerations will lead to a more robust and efficient power supply capable of handling high currents safely and effectively.The microcontroller won`t be able to drive the gate of Q1 very hard (usually GPIO pins can only source a few milliamps) so your turn-on and turn-off will be very slow. This will limit how well your high-side switch will behave. You don`t have a gate-to-source resistor on Q1, so you`re solely dependent on the GPIO keeping the MOSFET on or off.

If t he GPIO pin goes high-impedance, the MOSFET may turn itself on if the gate picks up a charge from the environment. which is crazy high power since D is going to be high (input is close to output). Also, the 225mA or so that will flow will also be burned in Q1, which isn`t healthy since it`s a relatively small device.

Your purely resistive feedback network is a bad idea. You really need some compensation and/or filtering. Your comparator will be hyper-fast and could react to switching noise, pickup, ripple, etc. - since you don`t seem to be using an error amplifier with compensation to control the gain and phase, you`re going to need some cap across R5 (and some luck). You don`t have input reverse-polarity protection and an input fuse in your power train. Big no-no, especially when the source is battery-based (big short-circuit sourcing capability). That being said, this isn`t a simple project by any stretch. Your schematic is largely incomplete and lacks basic safety protection that any power supply (especially ones that run at high power levels like yours) will need.

Even after the good answer by Madmanguruman, there are additional things that should be noted. The main difficulty with this design will be the high current being processed. I`ll pay attention mainly to the power processing components, power modulator, and filtering. Power FET is P channel. IRF4905: Rdson=0. 02@25C, 0. 034@150C; Ciss=3500pF. Conduction loss will be very high. For Vin=16. 8V, Vo=12V, Iout=40A, Pcond = $ ext{D } ext{Iout}2 ext{Rds}$ = (. 7)(1600)(0. 034) = 38W. After considering the thermal resistance of the TO220 package and case to sink junction, a heatsink with 2C/W will be required to meet 150C junction with an ambient temp of 25C. It is much better to use N channel FETs for high current situations. An otherwise equivalent N channel FET will have 1/3 the Rdson as a P channel FET. Gate Drive. There is no adequate gate drive in this design. Especially for turn off. With 70 Ohm turning off a FET with Ciss of 3500pF, turn off time will be at least 500nSec. This will mean huge switching loss in the FET, probably at least 15W of additional loss in the FET. This design has to have a much better gate drive. Since the gate drive needs to be improved anyway; it would be very beneficial to change to an N channel switching FET, and use a matching synchronous rectifier with a gate drive IC (like IR2104 or LM5104 or some such).

Hysteretic Control. There is no problem with constant on time, variable off time control. Hysteretic control can (if you are careful) work well, and have excellent transient response. But, the problem here is using the comparator in the uC. There needs to be access to the comparator to provide added hysteresis. So, a comparator with hysteresis, and with a response time less than 500nSec needs to be added. You would want to add hysteresis of about 100mV. Output filter. Good inductor, L1. At 40A plus ripple current it will be on the verge of saturation. It would be better to have a higher current part, but it is not a major concern. It looks like the output capacitors C1 and C2 are ceramic, which is a good choice, should be able to have a total ESR of less than 20 mOhms for a ripple voltage ~100mV. It is interesting, that the load resistance at maximum load (~0. 3 Ohms) is very close to the characteristic impedance of the output filter (~0. 2 Ohms). This is lucky, since it means that the filter is well damped, more about this later. If you are only driving motors with this supply there 🔗 External reference

The circuit design requires significant improvements in several areas to ensure reliable operation under high-current conditions. To enhance the gate drive, implementing a dedicated gate driver IC that can provide sufficient current to quickly charge and discharge the gate capacitance of the MOSFET is essential. This will minimize switching losses and improve overall efficiency. Transitioning to an N-channel MOSFET will also reduce conduction losses due to its lower Rdson.

Incorporating proper thermal management is crucial, especially considering the high power levels involved. This includes selecting appropriate heat sinks and ensuring adequate airflow around the components.

For the feedback network, using a combination of resistive and capacitive elements will help stabilize the control loop and mitigate the effects of noise and ripple. The addition of an error amplifier with compensation will enhance the performance of the comparator, allowing for better control of the output voltage and improved transient response.

The output filter design should also be revisited to ensure that it can handle the expected ripple current without saturating. Selecting an inductor with a higher current rating and ensuring that the capacitors are rated for the appropriate voltage and ripple current will enhance reliability.

Overall, addressing these design considerations will lead to a more robust and efficient power supply capable of handling high currents safely and effectively.The microcontroller won`t be able to drive the gate of Q1 very hard (usually GPIO pins can only source a few milliamps) so your turn-on and turn-off will be very slow. This will limit how well your high-side switch will behave. You don`t have a gate-to-source resistor on Q1, so you`re solely dependent on the GPIO keeping the MOSFET on or off.

If t he GPIO pin goes high-impedance, the MOSFET may turn itself on if the gate picks up a charge from the environment. which is crazy high power since D is going to be high (input is close to output). Also, the 225mA or so that will flow will also be burned in Q1, which isn`t healthy since it`s a relatively small device.

Your purely resistive feedback network is a bad idea. You really need some compensation and/or filtering. Your comparator will be hyper-fast and could react to switching noise, pickup, ripple, etc. - since you don`t seem to be using an error amplifier with compensation to control the gain and phase, you`re going to need some cap across R5 (and some luck). You don`t have input reverse-polarity protection and an input fuse in your power train. Big no-no, especially when the source is battery-based (big short-circuit sourcing capability). That being said, this isn`t a simple project by any stretch. Your schematic is largely incomplete and lacks basic safety protection that any power supply (especially ones that run at high power levels like yours) will need.

Even after the good answer by Madmanguruman, there are additional things that should be noted. The main difficulty with this design will be the high current being processed. I`ll pay attention mainly to the power processing components, power modulator, and filtering. Power FET is P channel. IRF4905: Rdson=0. 02@25C, 0. 034@150C; Ciss=3500pF. Conduction loss will be very high. For Vin=16. 8V, Vo=12V, Iout=40A, Pcond = $ ext{D } ext{Iout}2 ext{Rds}$ = (. 7)(1600)(0. 034) = 38W. After considering the thermal resistance of the TO220 package and case to sink junction, a heatsink with 2C/W will be required to meet 150C junction with an ambient temp of 25C. It is much better to use N channel FETs for high current situations. An otherwise equivalent N channel FET will have 1/3 the Rdson as a P channel FET. Gate Drive. There is no adequate gate drive in this design. Especially for turn off. With 70 Ohm turning off a FET with Ciss of 3500pF, turn off time will be at least 500nSec. This will mean huge switching loss in the FET, probably at least 15W of additional loss in the FET. This design has to have a much better gate drive. Since the gate drive needs to be improved anyway; it would be very beneficial to change to an N channel switching FET, and use a matching synchronous rectifier with a gate drive IC (like IR2104 or LM5104 or some such).

Hysteretic Control. There is no problem with constant on time, variable off time control. Hysteretic control can (if you are careful) work well, and have excellent transient response. But, the problem here is using the comparator in the uC. There needs to be access to the comparator to provide added hysteresis. So, a comparator with hysteresis, and with a response time less than 500nSec needs to be added. You would want to add hysteresis of about 100mV. Output filter. Good inductor, L1. At 40A plus ripple current it will be on the verge of saturation. It would be better to have a higher current part, but it is not a major concern. It looks like the output capacitors C1 and C2 are ceramic, which is a good choice, should be able to have a total ESR of less than 20 mOhms for a ripple voltage ~100mV. It is interesting, that the load resistance at maximum load (~0. 3 Ohms) is very close to the characteristic impedance of the output filter (~0. 2 Ohms). This is lucky, since it means that the filter is well damped, more about this later. If you are only driving motors with this supply there 🔗 External reference