Secret Ethernet optical wireless communication drive circuit diagram

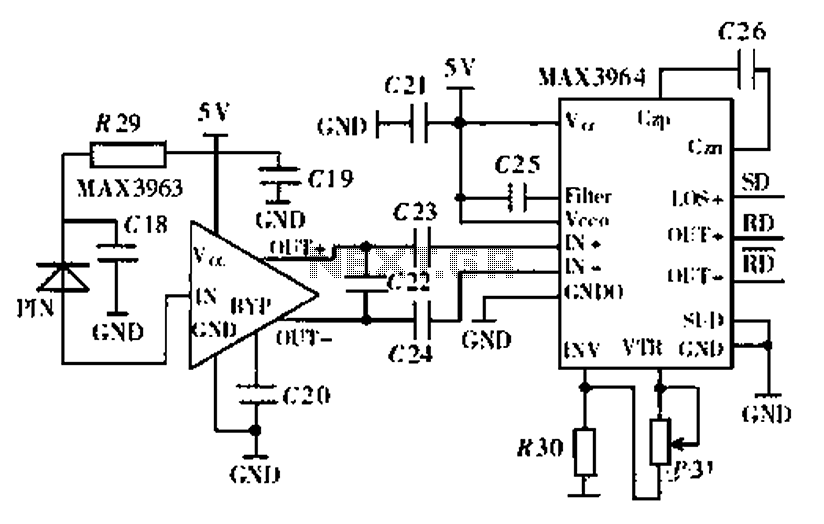

Ethernet is the most widely used networking technology, known for its high reliability, informative media, and ease of expansion and updates. It is commonly utilized in businesses, schools, and various other fields. According to the IEEE802.3 Ethernet specification, the length of each Ethernet coaxial cable should not exceed 500 meters, and the total distance through interconnected repeaters should not exceed 2.8 kilometers. In this context, wireless communication utilizing laser technology surpasses the geographical limitations of Ethernet data communication, offering significant practical value. The modulation driving circuit design includes a circuit diagram of a modulation driver, primarily composed of the MAXIM MAX3263 chip and an internal 155 MHz monitor diode laser (LD). The MAX3263 provides a temperature-compensated bias and reference voltage outputs (Vref1 and Vref2) through resistors R25, R26, R27, and R28, which are part of the internal high-speed modulation driver circuit. The output current of the MAX3263 is controlled by a mirror current source that compensates for the 2Vbe junction temperature drift, with the reference voltage set at 2Vbe to cancel this drift. Resistor R28 is selected to adjust the quiescent laser bias current (Ibo), which is set slightly below the laser's threshold current to ensure a favorable extinction ratio for the laser output. The internal monitor diode of the LD converts changes in light intensity into a current (Ipin), while the feedback current (Ibs) generated from this conversion is given by the formula Ibo = 40 (Ib + Ibs). This feedback mechanism stabilizes the laser bias current, ensuring consistent output optical power. The differential PECL signal RD is input from the internal high-speed buffer and output through a common-emitter differential modulator, where the modulation current size is determined by resistor R26. The selection of R26 is critical to achieve appropriate laser modulation current, sufficient output optical power, and a good extinction ratio. Additionally, the OUT+ and OUT- terminal voltages must be maintained at 2.2V or higher to prevent laser saturation. Given that the circuits depicted in Figures 6 and 7 operate above 155 MHz, careful selection of parameters and PCB design is essential for high-speed optical communications applications. System tests have been conducted based on the design of various components, successfully demonstrating indoor laser wireless Ethernet communication without optical antennas. The system is now improved and prepared for deployment in optical networks.

The described circuit utilizes the MAX3263 chip, which integrates a high-speed modulation driver capable of operating at frequencies exceeding 155 MHz. This feature is crucial for applications requiring rapid data transmission, such as Ethernet over laser communication. The modulation driver circuit is designed to accommodate the specific requirements of laser diodes, including the need for precise biasing and monitoring of output power.

The modulation driver employs a feedback mechanism that ensures the stability of the laser's output. By adjusting the resistor values, particularly R28 and R26, the circuit can optimize the laser's performance, balancing the extinction ratio and output power. The careful selection of resistors allows for fine-tuning of the modulation current, which is critical in maintaining signal integrity in high-speed communication systems.

The integration of a monitor diode within the laser diode assembly plays a pivotal role in maintaining consistent output power. As the light intensity fluctuates, the monitor diode generates a feedback current that is used to adjust the bias current, thereby stabilizing the output. This closed-loop control system is essential for preventing signal degradation, particularly in environments where temperature variations may affect diode performance.

The differential PECL signaling used in conjunction with the modulation driver enhances the robustness of the communication link. This signaling method is less susceptible to noise, making it suitable for high-speed data transmission. The circuit design must ensure that the output voltages remain within specified limits to prevent saturation of the laser, which can lead to signal distortion.

In summary, the modulation driving circuit design utilizing the MAX3263 chip is a sophisticated solution for high-speed laser-based Ethernet communication. The combination of precise biasing, feedback control, and differential signaling contributes to a reliable and efficient communication system capable of operating in various environments.Ethernet is the most widely used networking technology with high reliability, media informative, easy to expand and update, etc., in businesses, schools and other fields are wi dely used. According to the standard IEEE802.3 Ethernet specification, each Ethernet coaxial cable length should not exceed 500m, through the repeater interconnection network shall not exceed the maximum distance 2.8km. In this case, the wireless communications using laser technology, beyond the geographical limits of Ethernet data communication needs, has a strong practical value.

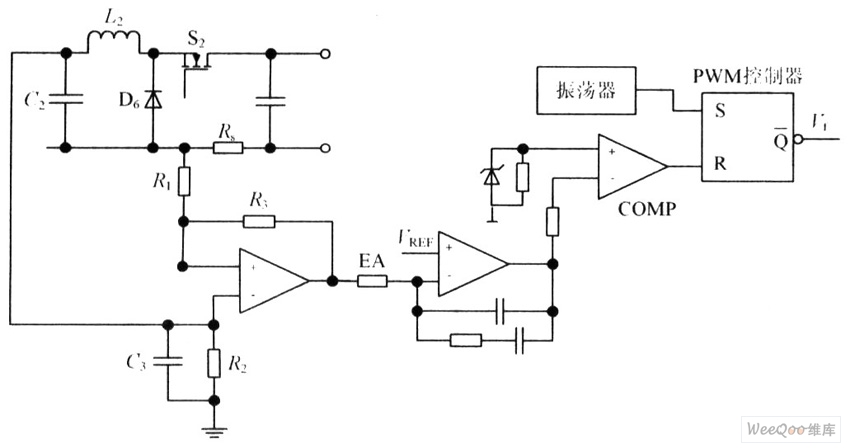

Modulation driving circuit design 6 is a circuit diagram of a modulation drive, mainly by MAXIMs MAX3263 chip and internal 155MHz with monitor diode laser LD constitution. MAX3263 main internal bias supply provides temperature compensated bias and reference voltage output Vref1 and Vref2, through a resistor R25, R26, R27 and R28 of the internal high-speed modulation driver circuit, laser diode and monitoring program.

MAX3263 output current are inside the mirror current source control, the current mirror has 2Vbe junction temperature drift, the reference voltage is set at 2Vbe, junction temperature drift can be canceled. Select resistor R28 to adjust the laser bias current quiescent Ibo, Ibo make slightly less than the laser threshold current, so that the output of the laser has a good extinction ratio.

LD internal monitor diode can light intensity change is converted to a current Ipin, the feedback current generated by the internal conversion Ibs, by the formula Ibo 40 (Ib + Ibs), light intensity change is converted into a portion of the laser bias current, feedback on laser, to ensure stable output optical power. Differential PECL signal RD input from the internal high-speed input buffer and output common-emitter differential-component modulator modulates the size of the modulation current is determined by the R26 current Im decision.

Select R26 size, make appropriate laser modulation current, sufficient output optical power, and has a good extinction ratio. At the same time should be OUT +, OUT- terminal voltage at 2.2V or more to prevent the laser saturation.

Because of Figures 6 and 7 are in the main chip 155MHz or more, so by the two circuit transceiver circuit, careful parameter selection and PCB design can be applied to high-speed optical communications applications. 5 system test on the basis of various parts of the design, the linking them, in the absence of optical antenna conditions, successfully conducted experiments indoor laser wireless Ethernet communication.

Improve the system now, and ready to be used in optical networks.

The described circuit utilizes the MAX3263 chip, which integrates a high-speed modulation driver capable of operating at frequencies exceeding 155 MHz. This feature is crucial for applications requiring rapid data transmission, such as Ethernet over laser communication. The modulation driver circuit is designed to accommodate the specific requirements of laser diodes, including the need for precise biasing and monitoring of output power.

The modulation driver employs a feedback mechanism that ensures the stability of the laser's output. By adjusting the resistor values, particularly R28 and R26, the circuit can optimize the laser's performance, balancing the extinction ratio and output power. The careful selection of resistors allows for fine-tuning of the modulation current, which is critical in maintaining signal integrity in high-speed communication systems.

The integration of a monitor diode within the laser diode assembly plays a pivotal role in maintaining consistent output power. As the light intensity fluctuates, the monitor diode generates a feedback current that is used to adjust the bias current, thereby stabilizing the output. This closed-loop control system is essential for preventing signal degradation, particularly in environments where temperature variations may affect diode performance.

The differential PECL signaling used in conjunction with the modulation driver enhances the robustness of the communication link. This signaling method is less susceptible to noise, making it suitable for high-speed data transmission. The circuit design must ensure that the output voltages remain within specified limits to prevent saturation of the laser, which can lead to signal distortion.

In summary, the modulation driving circuit design utilizing the MAX3263 chip is a sophisticated solution for high-speed laser-based Ethernet communication. The combination of precise biasing, feedback control, and differential signaling contributes to a reliable and efficient communication system capable of operating in various environments.Ethernet is the most widely used networking technology with high reliability, media informative, easy to expand and update, etc., in businesses, schools and other fields are wi dely used. According to the standard IEEE802.3 Ethernet specification, each Ethernet coaxial cable length should not exceed 500m, through the repeater interconnection network shall not exceed the maximum distance 2.8km. In this case, the wireless communications using laser technology, beyond the geographical limits of Ethernet data communication needs, has a strong practical value.

Modulation driving circuit design 6 is a circuit diagram of a modulation drive, mainly by MAXIMs MAX3263 chip and internal 155MHz with monitor diode laser LD constitution. MAX3263 main internal bias supply provides temperature compensated bias and reference voltage output Vref1 and Vref2, through a resistor R25, R26, R27 and R28 of the internal high-speed modulation driver circuit, laser diode and monitoring program.

MAX3263 output current are inside the mirror current source control, the current mirror has 2Vbe junction temperature drift, the reference voltage is set at 2Vbe, junction temperature drift can be canceled. Select resistor R28 to adjust the laser bias current quiescent Ibo, Ibo make slightly less than the laser threshold current, so that the output of the laser has a good extinction ratio.

LD internal monitor diode can light intensity change is converted to a current Ipin, the feedback current generated by the internal conversion Ibs, by the formula Ibo 40 (Ib + Ibs), light intensity change is converted into a portion of the laser bias current, feedback on laser, to ensure stable output optical power. Differential PECL signal RD input from the internal high-speed input buffer and output common-emitter differential-component modulator modulates the size of the modulation current is determined by the R26 current Im decision.

Select R26 size, make appropriate laser modulation current, sufficient output optical power, and has a good extinction ratio. At the same time should be OUT +, OUT- terminal voltage at 2.2V or more to prevent the laser saturation.

Because of Figures 6 and 7 are in the main chip 155MHz or more, so by the two circuit transceiver circuit, careful parameter selection and PCB design can be applied to high-speed optical communications applications. 5 system test on the basis of various parts of the design, the linking them, in the absence of optical antenna conditions, successfully conducted experiments indoor laser wireless Ethernet communication.

Improve the system now, and ready to be used in optical networks.