Slow Servo

Realistic flap and landing gear actuation.

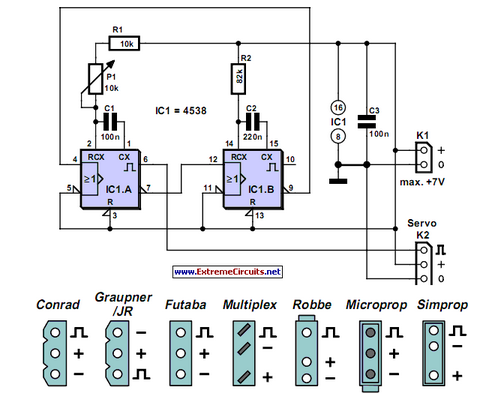

This circuit slows the speed of a conventional proportional servo. It regulates the time required for full servo rotation from 1 to 10 seconds without any reduction in the servo's torque, and every servo position is possible (proportional). More: It is suitable for:

* Landing gear

* Flaps

* Throttle control of gas-turbine engines

* LMH-110 (with modified hex file, see below) is very simple because it uses a microcontroller. Set-up is also very simple. First program the con

The described circuit is designed to provide smooth and realistic actuation for applications such as landing gear deployment, flap adjustments, and throttle control in gas-turbine engines. The core functionality is achieved through a microcontroller that manages the speed of a conventional proportional servo.

The circuit operates by regulating the pulse width modulation (PWM) signal sent to the servo, which directly influences its rotation speed. By adjusting the duty cycle of the PWM signal, the microcontroller can control the time it takes for the servo to move from one position to another. The design allows for a full range of motion, ensuring that the servo can achieve any position within its operational limits while maintaining its torque characteristics.

The timing for the servo's movement can be configured to range from 1 to 10 seconds, providing flexibility for different applications. This feature is particularly useful in modeling scenarios where realistic motion is required, such as in radio-controlled aircraft or other remote-controlled devices.

The setup process for this circuit is straightforward. Initially, the microcontroller must be programmed with the appropriate firmware, which includes the logic for controlling the servo speed and any specific parameters related to the application (e.g., timing settings for landing gear or flaps). The mention of modifying the hex file for the LMH-110 indicates that specific adjustments may be necessary to tailor the operation of the circuit for different hardware configurations.

In summary, the circuit is an effective solution for achieving realistic actuation in various applications, leveraging the capabilities of a microcontroller to provide precise control over servo movements while ensuring that torque is not compromised. This design is suitable for hobbyists and professionals alike, offering a simple yet powerful means of enhancing the functionality of proportional servos.Realistic flap and landing gear actuation. This circuit slows the speed of a conventional proportional servo. It regulates the time required for full servo rotation from 1 to 10 seconds without any reduction in the servo`s torque, and every servo position is possible (proportional). It is suitable for: * Landing gear * Flaps * Throttle control of gas-turbine engines * LMH-110 (with modified hex file, see below) is very simple because it uses a microcontroller. Set-up is also very simple. First program the con 🔗 External reference

This circuit slows the speed of a conventional proportional servo. It regulates the time required for full servo rotation from 1 to 10 seconds without any reduction in the servo's torque, and every servo position is possible (proportional). More: It is suitable for:

* Landing gear

* Flaps

* Throttle control of gas-turbine engines

* LMH-110 (with modified hex file, see below) is very simple because it uses a microcontroller. Set-up is also very simple. First program the con

The described circuit is designed to provide smooth and realistic actuation for applications such as landing gear deployment, flap adjustments, and throttle control in gas-turbine engines. The core functionality is achieved through a microcontroller that manages the speed of a conventional proportional servo.

The circuit operates by regulating the pulse width modulation (PWM) signal sent to the servo, which directly influences its rotation speed. By adjusting the duty cycle of the PWM signal, the microcontroller can control the time it takes for the servo to move from one position to another. The design allows for a full range of motion, ensuring that the servo can achieve any position within its operational limits while maintaining its torque characteristics.

The timing for the servo's movement can be configured to range from 1 to 10 seconds, providing flexibility for different applications. This feature is particularly useful in modeling scenarios where realistic motion is required, such as in radio-controlled aircraft or other remote-controlled devices.

The setup process for this circuit is straightforward. Initially, the microcontroller must be programmed with the appropriate firmware, which includes the logic for controlling the servo speed and any specific parameters related to the application (e.g., timing settings for landing gear or flaps). The mention of modifying the hex file for the LMH-110 indicates that specific adjustments may be necessary to tailor the operation of the circuit for different hardware configurations.

In summary, the circuit is an effective solution for achieving realistic actuation in various applications, leveraging the capabilities of a microcontroller to provide precise control over servo movements while ensuring that torque is not compromised. This design is suitable for hobbyists and professionals alike, offering a simple yet powerful means of enhancing the functionality of proportional servos.Realistic flap and landing gear actuation. This circuit slows the speed of a conventional proportional servo. It regulates the time required for full servo rotation from 1 to 10 seconds without any reduction in the servo`s torque, and every servo position is possible (proportional). It is suitable for: * Landing gear * Flaps * Throttle control of gas-turbine engines * LMH-110 (with modified hex file, see below) is very simple because it uses a microcontroller. Set-up is also very simple. First program the con 🔗 External reference