Solar Panel Based Charger And Small LED Lamp

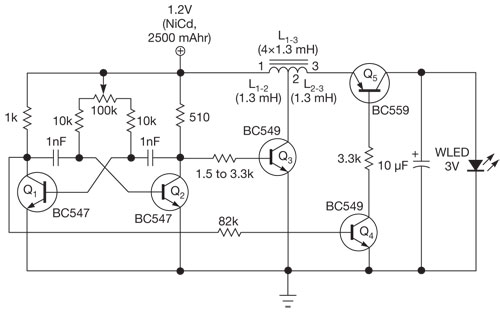

It is possible to reduce electricity bills by utilizing alternative power sources. The photovoltaic module, or solar panel, described here, can produce a power output of 5 watts. Under full sunlight conditions, the solar panel generates 16.5V and can deliver a current of 300 to 350 mA. This system can charge three types of batteries: lead-acid, Ni-Cd, and Li-ion. Lead-acid batteries are typically used in emergency lamps and uninterruptible power supplies (UPS). The circuit operates simply; the output from the solar panel is directed through diode 1N5402 (D1), which serves as a polarity guard to protect the solar panel. An ammeter is connected in series between diode D1 and a fuse to measure the current flowing during the battery charging process. As illustrated in Figure 1, an analog multimeter in the 500mA range is utilized. Diode D2 is included for protection against reverse polarity in the event of incorrect battery connections. If the polarity is reversed, the fuse will blow. To charge a lead-acid battery, switch S1 to the 'on' position and use connector A. Once the battery is connected, charging begins from the solar panel via diode D1, the multimeter, and the fuse. It is important to note that pulsating DC is optimal for charging lead-acid batteries. If this circuit is used for lead-acid battery charging, it should be replaced with a standard pulsating DC charger weekly. Regularly check the water level of the lead-acid battery, as pure DC voltage can cause sulfur deposition on the battery plates. For charging Ni-Cd cells, switches S1 and S3 should be turned to the 'on' position, and connector B should be used. Regulator IC 7806 (IC1) is configured as a constant-current source, with its output taken from the middle terminal (which is typically grounded). This setup provides a constant current to the Ni-Cd cells for charging, with a total of four 1.2V cells utilized. Resistor R2 limits the charging current. For charging Li-ion batteries (commonly used in mobile phones), switches S1 and S2 should be set to 'on', and connector C should be used. Regulator IC 7805 (IC2) supplies 5V for charging the Li-ion battery, allowing for easy charging of a 3.6V Li-ion cell. Resistor R3 is used to limit the charging current. Figure 2 depicts a basic LED-based lamp circuit, which is simple and cost-effective. Six 10mm white LEDs (LED2 through LED7) are connected in parallel and powered directly by a 3.6V DC source. Either pencil-type Ni-Cd batteries or rechargeable batteries can serve as the power source. The circuit should be assembled on a general-purpose PCB and enclosed in a small box. An RCA socket should be mounted on the front panel of the box, with an RCA plug wired to connect the battery and LED-based lamp to the charger.

The described photovoltaic module circuit provides a versatile solution for charging different types of batteries using solar energy. The inclusion of protective components such as diodes ensures the safety and longevity of both the solar panel and the batteries being charged. The use of an ammeter allows for monitoring of the charging current, which is essential for maintaining optimal charging conditions.

For lead-acid battery charging, the circuit's design emphasizes the importance of using pulsating DC to prevent sulfation on the battery plates. This is a critical consideration, as lead-acid batteries can suffer from reduced efficiency and lifespan if not charged correctly. The requirement to switch to a standard pulsating DC charger weekly is a practical approach to maintaining battery health.

The charging circuits for Ni-Cd and Li-ion batteries incorporate voltage regulators to ensure stable and appropriate charging currents. The 7806 and 7805 voltage regulators are widely used in electronic circuits for their reliability and ease of use. By configuring these regulators correctly, the circuit can provide the necessary current while preventing overcharging, which is crucial for maintaining battery performance and safety.

The LED-based lamp circuit demonstrates a straightforward application of the power generated by the solar panel. By using parallel connections for the LEDs, the circuit minimizes complexity while maximizing light output. The choice of using rechargeable batteries for this application aligns with the overall goal of sustainability and energy efficiency.

In conclusion, this solar-powered charging circuit not only offers a cost-effective solution for battery charging but also promotes the use of renewable energy sources, contributing to reduced electricity costs and environmental sustainability. The design considerations and component selections ensure that the circuit operates efficiently and safely across different battery types.You can save on your electricity bills by switching to alternative sources of power. The photovoltaic module or solar panel described here is capable of delivering a power of 5 watts. At full sunlight, the solar panel outputs 16. 5V. It can deliver a current of 300-350 mA. Using it you can charge three types of batteries: lead acid, Ni-Cd and Li-io n. The lead-acid batteries are commonly used in emergency lamps and UPS. The working of the circuit is simple. The output of the solar panel is fed via diode 1N5402 (D1), which acts as a polarity guard and protects the solar panel. An ammeter is connected in series between diode D1 and fuse to measure the current flowing during charging of the batteries.

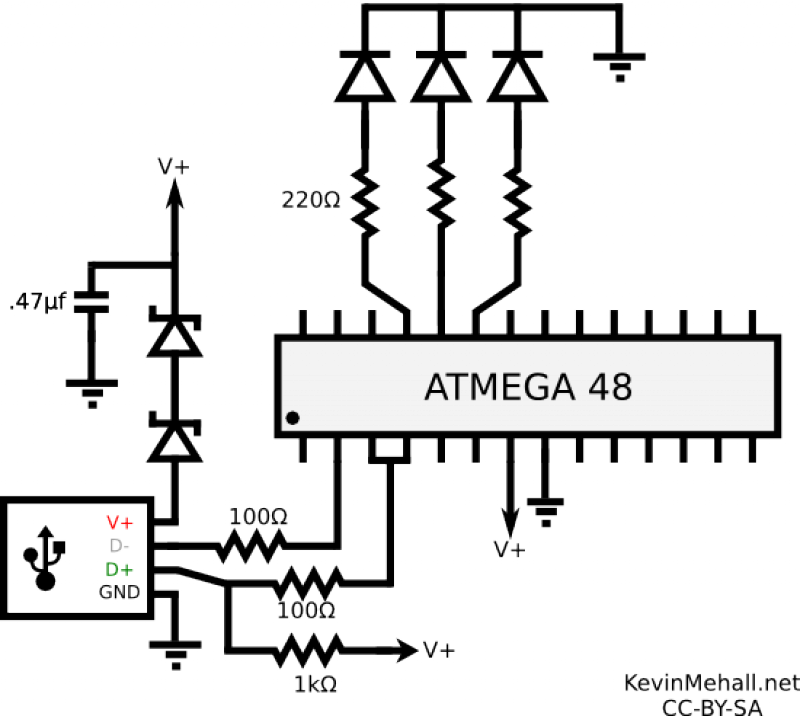

As shown in Fig. 1, we have used an analogue multimeter in 500mA range. Diode D2 is used for protection against reverse polarity in case of wrong connection of the lead-acid battery. When you connect wrong polarity, the fuse will blow up. For charging a lead-acid battery, shift switch S1 to on` position and use connector A. ` After you connect the battery, charging starts from the solar panel via diode D1, multimeter and fuse.

Note that pulsating DC is the best for charging lead-acid batteries. If you use this circuit for charging a lead-acid battery, replace it with a normal pulsating DC charger once a week. Keep checking the water level of the lead-acid battery. Pure DC voltage normally leads to deposition of sulphur on the plates of lead-acid batteries. For charging Ni-Cd cells, shift switches S1 and S3 to on` position and use connector B. ` Regulator IC 7806 (IC1) is wired as a constant-current source and its output is taken from the middle terminal (normally grounded).

Using this circuit, a constant current goes to Ni-Cd cell for charging. A total of four 1. 2V cells are used here. Resistor R2 limits the charging current. For charging Li-ion battery (used in mobile phones), shift switches S1 and S2 to on` position and use connector C. ` Regulator IC 7805 (IC2) provides 5V for charging the Li-ion battery. Using this circuit, you can charge a 3. 6V Li-ion cell very easily. Resistor R3 limits the charging current. Fig. 2 shows the circuit for a small LED-based lamp. It is simple and low-cost. Six 10mm white LEDs (LED2 through LED7) are used here. Just connect them in parallel and drive directly by a 3. 6V DC source. You can use either pencil-type Ni-Cd batteries or rechargeable batteries as the power source. Assemble the circuit on a general-purpose PCB and enclose in a small box. Mount RCA socket on the front panel of the box and wire RCA plug with cable for connecting the battery and LED-based lamp to the charger.

🔗 External reference

The described photovoltaic module circuit provides a versatile solution for charging different types of batteries using solar energy. The inclusion of protective components such as diodes ensures the safety and longevity of both the solar panel and the batteries being charged. The use of an ammeter allows for monitoring of the charging current, which is essential for maintaining optimal charging conditions.

For lead-acid battery charging, the circuit's design emphasizes the importance of using pulsating DC to prevent sulfation on the battery plates. This is a critical consideration, as lead-acid batteries can suffer from reduced efficiency and lifespan if not charged correctly. The requirement to switch to a standard pulsating DC charger weekly is a practical approach to maintaining battery health.

The charging circuits for Ni-Cd and Li-ion batteries incorporate voltage regulators to ensure stable and appropriate charging currents. The 7806 and 7805 voltage regulators are widely used in electronic circuits for their reliability and ease of use. By configuring these regulators correctly, the circuit can provide the necessary current while preventing overcharging, which is crucial for maintaining battery performance and safety.

The LED-based lamp circuit demonstrates a straightforward application of the power generated by the solar panel. By using parallel connections for the LEDs, the circuit minimizes complexity while maximizing light output. The choice of using rechargeable batteries for this application aligns with the overall goal of sustainability and energy efficiency.

In conclusion, this solar-powered charging circuit not only offers a cost-effective solution for battery charging but also promotes the use of renewable energy sources, contributing to reduced electricity costs and environmental sustainability. The design considerations and component selections ensure that the circuit operates efficiently and safely across different battery types.You can save on your electricity bills by switching to alternative sources of power. The photovoltaic module or solar panel described here is capable of delivering a power of 5 watts. At full sunlight, the solar panel outputs 16. 5V. It can deliver a current of 300-350 mA. Using it you can charge three types of batteries: lead acid, Ni-Cd and Li-io n. The lead-acid batteries are commonly used in emergency lamps and UPS. The working of the circuit is simple. The output of the solar panel is fed via diode 1N5402 (D1), which acts as a polarity guard and protects the solar panel. An ammeter is connected in series between diode D1 and fuse to measure the current flowing during charging of the batteries.

As shown in Fig. 1, we have used an analogue multimeter in 500mA range. Diode D2 is used for protection against reverse polarity in case of wrong connection of the lead-acid battery. When you connect wrong polarity, the fuse will blow up. For charging a lead-acid battery, shift switch S1 to on` position and use connector A. ` After you connect the battery, charging starts from the solar panel via diode D1, multimeter and fuse.

Note that pulsating DC is the best for charging lead-acid batteries. If you use this circuit for charging a lead-acid battery, replace it with a normal pulsating DC charger once a week. Keep checking the water level of the lead-acid battery. Pure DC voltage normally leads to deposition of sulphur on the plates of lead-acid batteries. For charging Ni-Cd cells, shift switches S1 and S3 to on` position and use connector B. ` Regulator IC 7806 (IC1) is wired as a constant-current source and its output is taken from the middle terminal (normally grounded).

Using this circuit, a constant current goes to Ni-Cd cell for charging. A total of four 1. 2V cells are used here. Resistor R2 limits the charging current. For charging Li-ion battery (used in mobile phones), shift switches S1 and S2 to on` position and use connector C. ` Regulator IC 7805 (IC2) provides 5V for charging the Li-ion battery. Using this circuit, you can charge a 3. 6V Li-ion cell very easily. Resistor R3 limits the charging current. Fig. 2 shows the circuit for a small LED-based lamp. It is simple and low-cost. Six 10mm white LEDs (LED2 through LED7) are used here. Just connect them in parallel and drive directly by a 3. 6V DC source. You can use either pencil-type Ni-Cd batteries or rechargeable batteries as the power source. Assemble the circuit on a general-purpose PCB and enclose in a small box. Mount RCA socket on the front panel of the box and wire RCA plug with cable for connecting the battery and LED-based lamp to the charger.

🔗 External reference