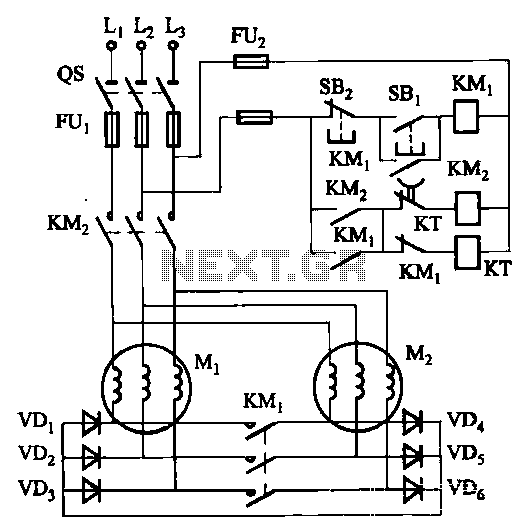

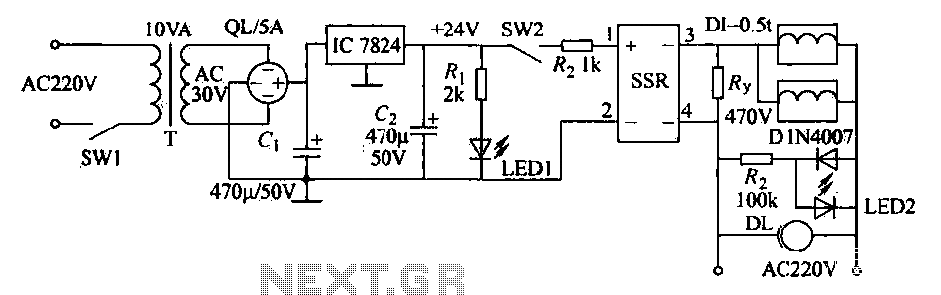

Solenoid control circuit

An AC solenoid-driven control circuit utilizing the SSR principle is illustrated. When switch SW1 is closed, a 220V AC transformer steps down the voltage to 30V AC through transformer T. The circuit includes a rectifier, capacitor C, and a filter regulator IC (IC7824), which outputs a +24V supply for the solenoid control circuit. The power indicator LED1 (red) illuminates. This circuit is designed for ironworks and foundries, facilitating the operation of an electromagnetic crane capable of lifting 0.5 tons of pig iron. The crane moves raw materials (iron) to a designated location, where they are deposited in an iron heap. Closing switch SW2 activates solid-state relay SSR1, allowing current to flow to the solenoid, energizing it to lift the iron. The electric hoist utilizes electromagnets to raise the warm iron raw material to the cupola. Upon disconnecting switch SW2, the pig iron is released into the furnace, accompanied by the illumination of LED2 (green) as a work indicator, and an alarm (DL) sounds to alert personnel to safety.

An AC solenoid-driven control circuit employing a solid-state relay (SSR) operates efficiently for industrial applications, particularly in ironworks and foundries. The circuit begins with a 220V AC power supply, which is transformed to a lower voltage of 30V AC using transformer T. This step-down voltage is crucial for safe operation and compatibility with the subsequent components.

The circuit features a rectifier that converts the AC voltage to a pulsating DC voltage. This is followed by capacitor C, which smoothens the rectified voltage, providing a more stable DC output. The filter regulator IC7824 plays a pivotal role in this setup, regulating the voltage to a precise +24V, which is necessary for the solenoid control circuit to function correctly.

The circuit is equipped with a power indicator LED1 (red), which provides visual feedback that the circuit is powered and operational. This is particularly important in industrial settings where multiple systems may be in operation.

The electromagnetic crane, capable of lifting up to 0.5 tons of pig iron, is controlled through the operation of switches SW1 and SW2. When SW1 is closed, the circuit is energized, allowing the operator to control the crane's movements. The crane's electromagnet is activated when switch SW2 is closed, which energizes solid-state relay SSR1. This relay is designed for high efficiency and reliability, ensuring that the solenoid receives the necessary power to lift the iron.

As the crane lifts the warm iron, it transports it to the cupola, a furnace used for melting iron. The circuit includes safety features, such as the activation of LED2 (green) to indicate that the operation is in progress and an alarm (DL) that sounds to alert personnel of the ongoing operation, emphasizing the importance of safety in industrial environments.

Upon releasing the switch SW2, the circuit disconnects, allowing the pig iron to fall into the furnace. This process is seamless and ensures that operations can be conducted safely and efficiently, highlighting the importance of precise control in industrial automation systems. The design and implementation of this circuit demonstrate a robust approach to managing heavy lifting tasks within a foundry setting.AC solenoid driven control with SSR principle is shown in Fig. The switch is closed SW1,220V AC transformer through the transformer T to AC 30V, the QL crossing barrier rectifier; capacitance C. , G filter, regulator IC IC7824 output + 24V supply solenoid control circuit, power indicator LED1 (red) lights up. This circuit is used ironworks, foundry iron with feeding electromagnetic crane (one can lift 0.5t pig iron).

Move motion hoist electromagnetic crane to move raw materials (iron) position, dropped to iron heap. Closes the switch SW2, solid state relay SSR1 eligible for the positive supply terminal is turned, SSR fine the end and feet conduction, solenoid is energized DT absorption of iron. Electric hoist lifting electromagnets. The warm iron raw material to the cupola, disconnect switch SW2, pig iron fall within the furnace, there are lights LED2 (green) indication at work.

And a DL alarm sound, indicating that people pay attention to safety.

An AC solenoid-driven control circuit employing a solid-state relay (SSR) operates efficiently for industrial applications, particularly in ironworks and foundries. The circuit begins with a 220V AC power supply, which is transformed to a lower voltage of 30V AC using transformer T. This step-down voltage is crucial for safe operation and compatibility with the subsequent components.

The circuit features a rectifier that converts the AC voltage to a pulsating DC voltage. This is followed by capacitor C, which smoothens the rectified voltage, providing a more stable DC output. The filter regulator IC7824 plays a pivotal role in this setup, regulating the voltage to a precise +24V, which is necessary for the solenoid control circuit to function correctly.

The circuit is equipped with a power indicator LED1 (red), which provides visual feedback that the circuit is powered and operational. This is particularly important in industrial settings where multiple systems may be in operation.

The electromagnetic crane, capable of lifting up to 0.5 tons of pig iron, is controlled through the operation of switches SW1 and SW2. When SW1 is closed, the circuit is energized, allowing the operator to control the crane's movements. The crane's electromagnet is activated when switch SW2 is closed, which energizes solid-state relay SSR1. This relay is designed for high efficiency and reliability, ensuring that the solenoid receives the necessary power to lift the iron.

As the crane lifts the warm iron, it transports it to the cupola, a furnace used for melting iron. The circuit includes safety features, such as the activation of LED2 (green) to indicate that the operation is in progress and an alarm (DL) that sounds to alert personnel of the ongoing operation, emphasizing the importance of safety in industrial environments.

Upon releasing the switch SW2, the circuit disconnects, allowing the pig iron to fall into the furnace. This process is seamless and ensures that operations can be conducted safely and efficiently, highlighting the importance of precise control in industrial automation systems. The design and implementation of this circuit demonstrate a robust approach to managing heavy lifting tasks within a foundry setting.AC solenoid driven control with SSR principle is shown in Fig. The switch is closed SW1,220V AC transformer through the transformer T to AC 30V, the QL crossing barrier rectifier; capacitance C. , G filter, regulator IC IC7824 output + 24V supply solenoid control circuit, power indicator LED1 (red) lights up. This circuit is used ironworks, foundry iron with feeding electromagnetic crane (one can lift 0.5t pig iron).

Move motion hoist electromagnetic crane to move raw materials (iron) position, dropped to iron heap. Closes the switch SW2, solid state relay SSR1 eligible for the positive supply terminal is turned, SSR fine the end and feet conduction, solenoid is energized DT absorption of iron. Electric hoist lifting electromagnets. The warm iron raw material to the cupola, disconnect switch SW2, pig iron fall within the furnace, there are lights LED2 (green) indication at work.

And a DL alarm sound, indicating that people pay attention to safety.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713