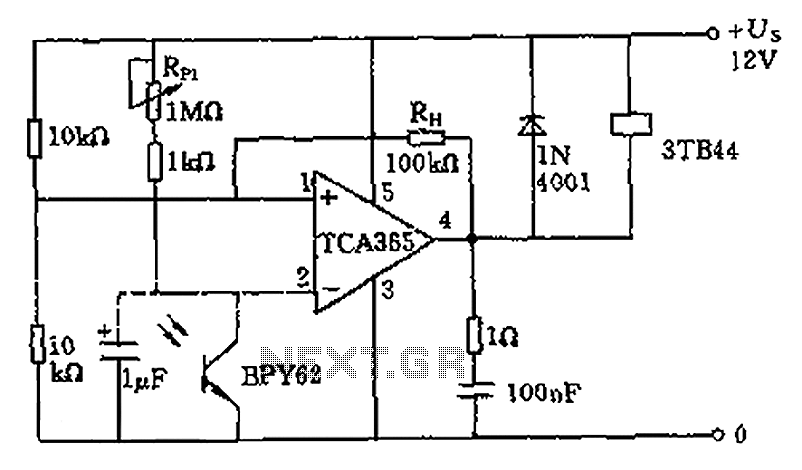

Synchronized TRIAC for Small Induction Motor Speed Control

This circuit diagram can be utilized to adjust the speed of a low-power induction motor, commonly found in fan applications.

The circuit for controlling the speed of a low-power induction motor typically employs a variable frequency drive (VFD) or a phase control method. In this application, a triac or a solid-state relay may be used to modulate the power supplied to the motor. The key components in the circuit include a microcontroller or a potentiometer for setting the desired speed, a triac for switching the motor on and off, and necessary protection components such as fuses and diodes to prevent damage from voltage spikes.

The microcontroller can be programmed to adjust the duty cycle of the signal sent to the triac, thereby controlling the effective voltage and frequency supplied to the motor. This modulation results in varying speeds of the motor, allowing for precise control based on the application requirements.

In addition, feedback mechanisms can be implemented to monitor the motor's speed and adjust the control signals accordingly. This can enhance performance and efficiency, particularly in applications where speed regulation is critical. The design should also incorporate heat sinks or cooling mechanisms to dissipate heat generated by the triac during operation, ensuring reliability and longevity of the circuit.

Overall, the circuit design should prioritize safety and efficiency, with appropriate ratings for all components to handle the expected load and environmental conditions. Proper layout and grounding techniques should be employed to minimize noise and interference, which can affect the operation of the motor and the overall performance of the system.We can use this circuit diagram to adjust the speed of a low-power induction motor, such as those which can be found in fan application. The function of. 🔗 External reference

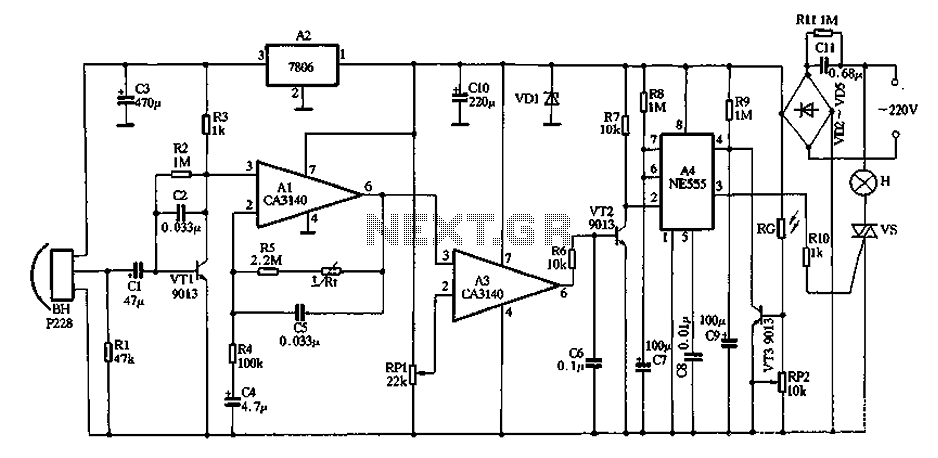

The circuit for controlling the speed of a low-power induction motor typically employs a variable frequency drive (VFD) or a phase control method. In this application, a triac or a solid-state relay may be used to modulate the power supplied to the motor. The key components in the circuit include a microcontroller or a potentiometer for setting the desired speed, a triac for switching the motor on and off, and necessary protection components such as fuses and diodes to prevent damage from voltage spikes.

The microcontroller can be programmed to adjust the duty cycle of the signal sent to the triac, thereby controlling the effective voltage and frequency supplied to the motor. This modulation results in varying speeds of the motor, allowing for precise control based on the application requirements.

In addition, feedback mechanisms can be implemented to monitor the motor's speed and adjust the control signals accordingly. This can enhance performance and efficiency, particularly in applications where speed regulation is critical. The design should also incorporate heat sinks or cooling mechanisms to dissipate heat generated by the triac during operation, ensuring reliability and longevity of the circuit.

Overall, the circuit design should prioritize safety and efficiency, with appropriate ratings for all components to handle the expected load and environmental conditions. Proper layout and grounding techniques should be employed to minimize noise and interference, which can affect the operation of the motor and the overall performance of the system.We can use this circuit diagram to adjust the speed of a low-power induction motor, such as those which can be found in fan application. The function of. 🔗 External reference