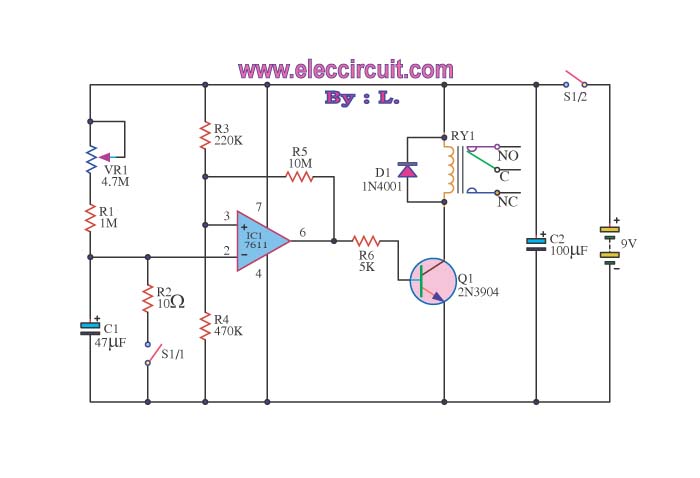

Temperature Controler switch

This circuit controls a load (in this case a DC brushless fan) based on a temperature compared with a setpoint. The transducer is a diode in the forward polarization regime. In fact, when forward biased, the forward voltage drop across a diode has a temperature dependence, in particular has a negative linear slope. This is because of the Boltzmann distribution, causing electrons to pass to the conduction band thermally, lowering the voltage drop across the diode. This circuit compares a precise voltage reference (Zener) with the forward voltage drop of the diode forward biased with 11mA of current. The comparator is simply a LM158/258/358 working in open-loop mode, the inverting input is connected to the diode sensor, and the non-inverting to the reference voltage. When the temperature rises above the setpoint, the forward voltage drops under the voltage reference and the comparator output is activating the transistor and thus the fan.

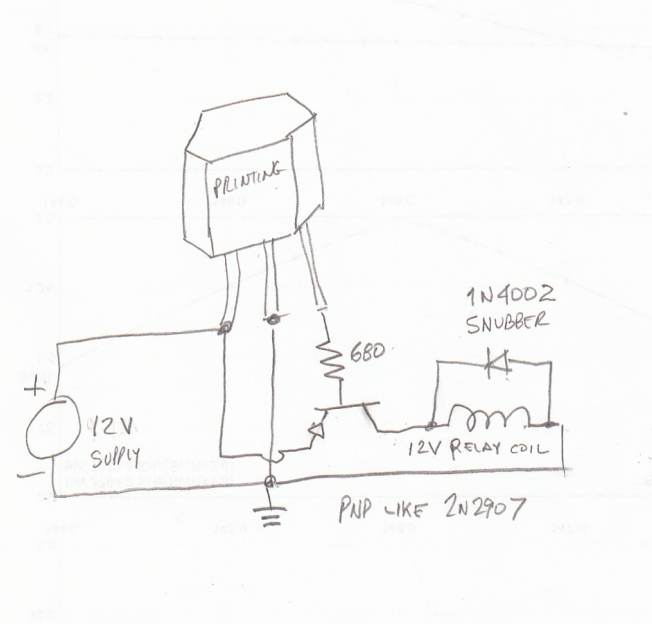

Higher power transistors can be substituted for bigger fans, or a relay, IGBT, MOSFET, etc., can be used to control higher loads (and higher voltages).

The setpoint is adjusted with the potentiometer, and a LM3914 LED driver can be employed to create a temperature setpoint indicator (requiring careful calibration and the use of Excel to calculate slope and intercept).

Many modifications can be made, but the circuit works very well in its basic form.

The comparator can distinguish 10µV differences, equating to approximately 0.01°C differences (carefully adjusting the potentiometer can allow detection of body heat from 1/2 cm from the sensor or ambient heat, causing the fan to turn on and off continuously).

Temperature control is possible up to 140°C (150°C maximum diode temperature), but linearity is not ensured.

Possible applications include heatsink cooling, emergency computer cooling (though a linear device may be preferable to an on-off configuration), and metal cooling during drilling, among others.

This circuit can also be adapted for heating applications by reversing the comparator inputs and substituting the fan with a relay that controls the heater.

The circuit employs a basic design that leverages the temperature-dependent characteristics of a diode to provide a reliable and responsive control mechanism for fans or heating elements. The use of a Zener diode as a reference voltage source ensures precision in temperature detection, while the LM158/258/358 operational amplifier functions as a comparator to switch the load based on the setpoint. Adjustability is facilitated through a potentiometer, allowing for fine-tuning of the desired operating temperature. The circuit's versatility enables it to be applied in various thermal management scenarios, making it a practical solution for both cooling and heating applications.This circuit controls a load (in this case a dc brushless fan) based on a temperature compared with a setpoint. THe transduced is a diode in the forward polarization regime. In fact when forward biased, the forward voltage drop accross a diode has a temperature dependance, in particular has a negative linear(ish) slope.

This because of the boltzmann distribuition, causing electrons to pass to the conduction band thermically, lowering the voltage drop accross the diode. Anyway this circuit comparates a precise voltage reference (zener) with the forward voltage drop of the diode forward biased with 11mA of current.

The comparator is simply a LM158/258/358 working in open-loop mode, the inverting input is connected to the diode sensor, and the noninverting to the reference voltage. Se when the temperature rises above the setpoint, the forward voltage drops under the voltage reference and the comparator output is vccturning on the transistor and so the fan.

Higher power transistor can be substituted for bigger fans, or you can substitute a relay, IGBT, mosfet etc to control higher loads (and higher voltages). The setpoint is adjusted with the potentiometer, and you can use a LM3914 led driver to make a temperature setpoint indicator (needs careful calibrations and the use of excel to calculate slope and intercept).

Many modifications can be done, but the circuit works very well in its basic form. THe comparator can distinguish 10uV differences so approx 0.01°C differences (carefully adjusting the potentiometer can allow to feel body heat from 1/2 cm from the sensor, or feel ambient heat, making to turn the fan on and off continuosly) You can control temperatures up to 140°C (150 max diode temperature), but linearity is not ensured Possible uses? Heatsink cooling, computer emergency cooling (but i thint that a linear device would be better than a on-off) metal cooling when drilling etc...

Ah! One note: you can even heat with this circuit but you need the reverse comparator inputs and substitute the fan with a relay controlling the heater. 🔗 External reference

Higher power transistors can be substituted for bigger fans, or a relay, IGBT, MOSFET, etc., can be used to control higher loads (and higher voltages).

The setpoint is adjusted with the potentiometer, and a LM3914 LED driver can be employed to create a temperature setpoint indicator (requiring careful calibration and the use of Excel to calculate slope and intercept).

Many modifications can be made, but the circuit works very well in its basic form.

The comparator can distinguish 10µV differences, equating to approximately 0.01°C differences (carefully adjusting the potentiometer can allow detection of body heat from 1/2 cm from the sensor or ambient heat, causing the fan to turn on and off continuously).

Temperature control is possible up to 140°C (150°C maximum diode temperature), but linearity is not ensured.

Possible applications include heatsink cooling, emergency computer cooling (though a linear device may be preferable to an on-off configuration), and metal cooling during drilling, among others.

This circuit can also be adapted for heating applications by reversing the comparator inputs and substituting the fan with a relay that controls the heater.

The circuit employs a basic design that leverages the temperature-dependent characteristics of a diode to provide a reliable and responsive control mechanism for fans or heating elements. The use of a Zener diode as a reference voltage source ensures precision in temperature detection, while the LM158/258/358 operational amplifier functions as a comparator to switch the load based on the setpoint. Adjustability is facilitated through a potentiometer, allowing for fine-tuning of the desired operating temperature. The circuit's versatility enables it to be applied in various thermal management scenarios, making it a practical solution for both cooling and heating applications.This circuit controls a load (in this case a dc brushless fan) based on a temperature compared with a setpoint. THe transduced is a diode in the forward polarization regime. In fact when forward biased, the forward voltage drop accross a diode has a temperature dependance, in particular has a negative linear(ish) slope.

This because of the boltzmann distribuition, causing electrons to pass to the conduction band thermically, lowering the voltage drop accross the diode. Anyway this circuit comparates a precise voltage reference (zener) with the forward voltage drop of the diode forward biased with 11mA of current.

The comparator is simply a LM158/258/358 working in open-loop mode, the inverting input is connected to the diode sensor, and the noninverting to the reference voltage. Se when the temperature rises above the setpoint, the forward voltage drops under the voltage reference and the comparator output is vccturning on the transistor and so the fan.

Higher power transistor can be substituted for bigger fans, or you can substitute a relay, IGBT, mosfet etc to control higher loads (and higher voltages). The setpoint is adjusted with the potentiometer, and you can use a LM3914 led driver to make a temperature setpoint indicator (needs careful calibrations and the use of excel to calculate slope and intercept).

Many modifications can be done, but the circuit works very well in its basic form. THe comparator can distinguish 10uV differences so approx 0.01°C differences (carefully adjusting the potentiometer can allow to feel body heat from 1/2 cm from the sensor, or feel ambient heat, making to turn the fan on and off continuosly) You can control temperatures up to 140°C (150 max diode temperature), but linearity is not ensured Possible uses? Heatsink cooling, computer emergency cooling (but i thint that a linear device would be better than a on-off) metal cooling when drilling etc...

Ah! One note: you can even heat with this circuit but you need the reverse comparator inputs and substitute the fan with a relay controlling the heater. 🔗 External reference