simple gauss detection switch

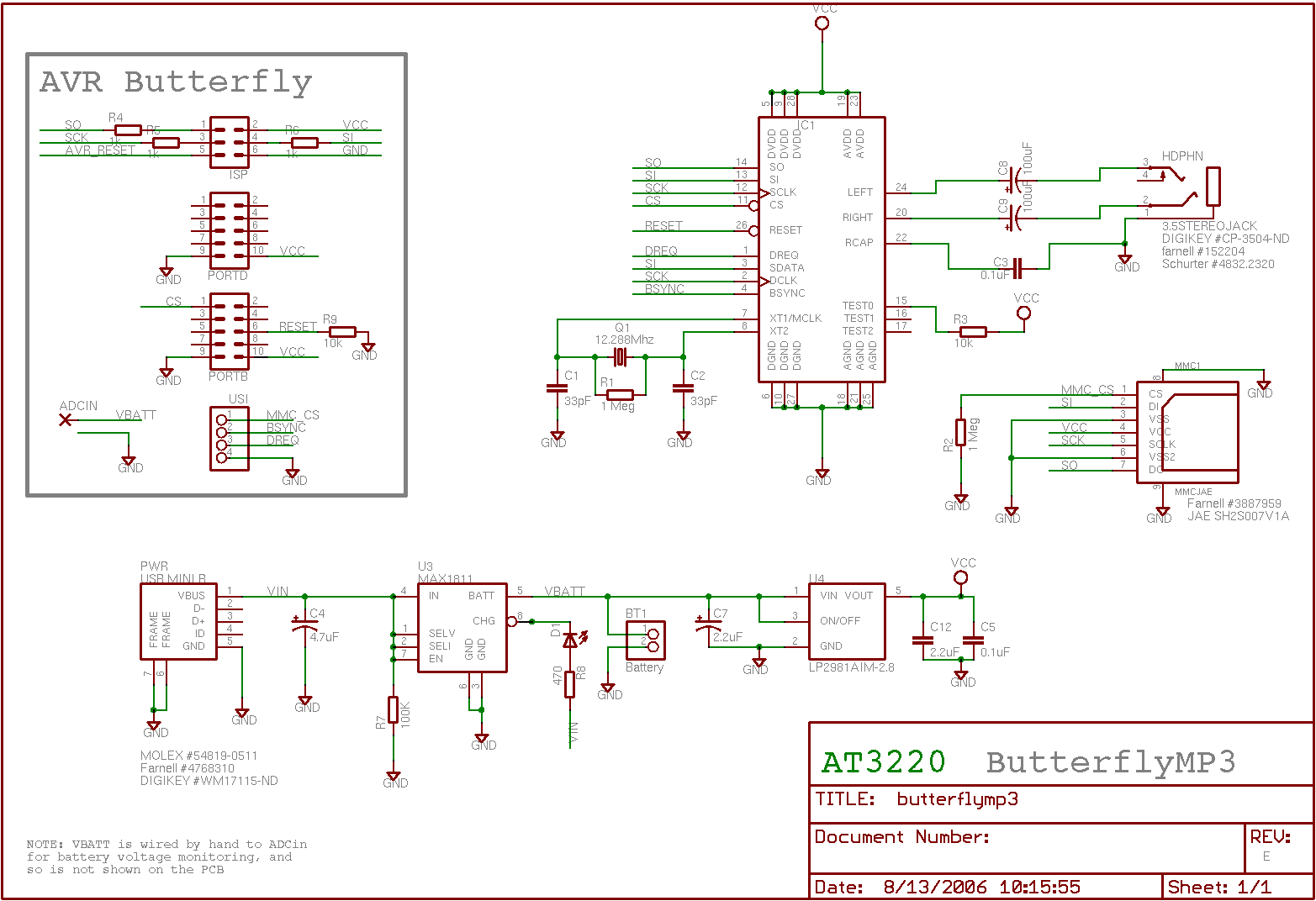

An ultra-sensitive gauss meter circuit schematic serves as a simple indicator with no measurement, scaling, or accuracy. It consists of a Hall effect device or integrated circuit on a board with power supply inputs, minimal signal conditioning comprising approximately a dozen additional components, and a small relay. The linear Hall effect sensor produces an output of 1.3mV per Gauss, which may represent a limitation of Hall effect sensors in general. This raises questions regarding the infrequent use of Hall effect sensors in applications like compasses, where magneto-resistive or magneto-inductive sensors are more common, despite their complexity and limited availability. The feasibility of implementing such a simple circuit is under consideration, as sensitivity is contingent upon the integrated circuit used. Ongoing testing of a specific component may yield favorable results, although inquiries have not led to substantial progress. The goal is to create an ultra-sensitive switch circuit, with experimentation involving the placement of the sensor chip within various ferrite rings to enhance sensitivity.

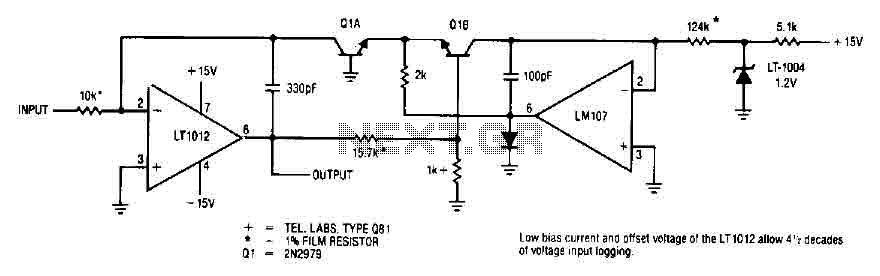

The ultra-sensitive gauss meter circuit is designed to detect magnetic fields with high sensitivity, utilizing a Hall effect sensor, which is a transducer that varies its output voltage in response to a magnetic field. The circuit typically includes a power supply section that provides the necessary voltage to the Hall sensor and other components. The Hall effect sensor generates a small voltage output, approximately 1.3mV per Gauss, which necessitates signal conditioning to amplify and filter this signal for practical use.

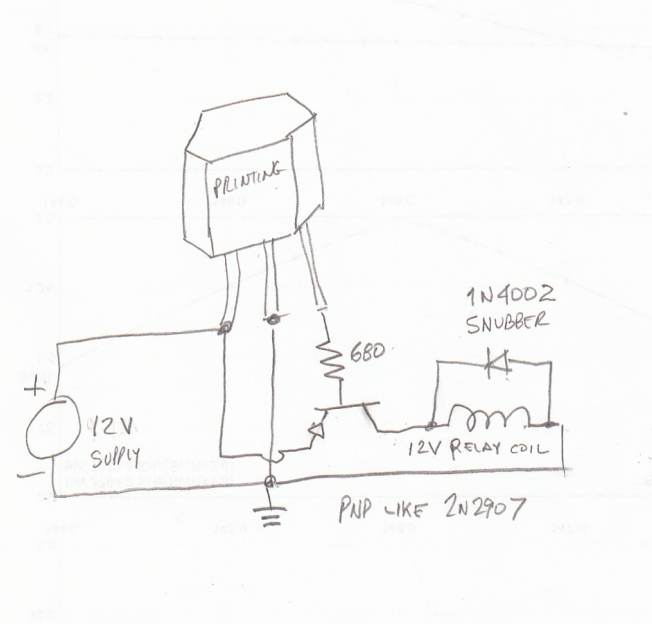

Signal conditioning may involve operational amplifiers to increase the output voltage, along with resistors and capacitors to form filters that eliminate noise and stabilize the output. This ensures that the small variations in voltage can be accurately interpreted by subsequent circuitry. A relay may be included in the design to act as a switch that activates or deactivates a load based on the detected magnetic field strength.

The choice of the Hall effect sensor integrated circuit is crucial, as its characteristics will determine the overall sensitivity and performance of the circuit. The circuit may be optimized by experimenting with the placement of the sensor within ferrite rings, which can enhance the magnetic field's strength at the sensor's location, thereby improving the sensitivity of the measurement.

While magneto-resistive and magneto-inductive sensors are alternatives used in applications like compasses, they are often more complex and less accessible than Hall effect sensors. The simplicity of the Hall effect sensor circuit makes it an attractive option for various applications, provided that the limitations of the sensor are understood and addressed. Overall, this circuit can serve as a foundational design for those seeking to create a sensitive magnetic field detection system with minimal complexity.An ultra sensitive gauss meter circuit/schematic anywhere that constitutes a simple indicator No measurement. No scaling. No accuracy. Just hall device/ic on a board with power supply inputs, a bit of signal conditioning of maybe a dozen more parts, and a little relay.

If you look at the linear hall effect sensor it has an output of 1. 3mV per Gauss. That might be the limitation of hall effect sensors in general which might be where all your problems are coming from. It`s got me wondering why you never see hall effect sensors in things like compasses. You always see some kind of magneto-resistive or magneto-inductive sensor for those kinds of things, but those are neither straightforward to work with, nor easily available. Is it possible to implement so simple a circuit Or are these merely rough application examples Sensitivity would only depend on the IC that is inserted, no I`m in the process of testing that last one and it may work for me.

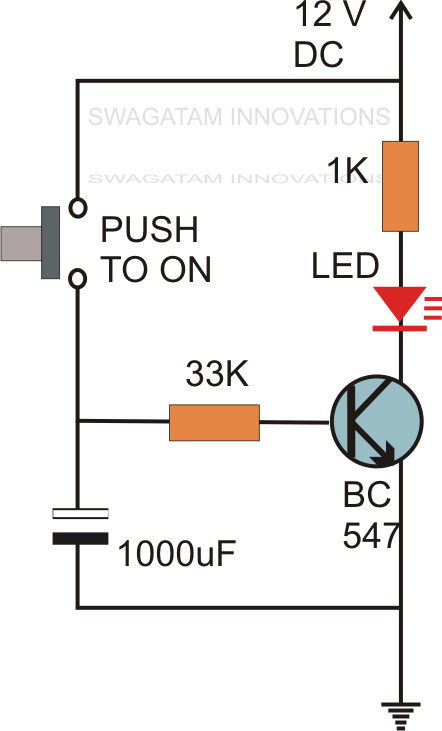

But I`ve asked a few questions about it here and elsewhere and don`t seem to be making any headway. The simpler the better. I just want an ultra sensitive switch circuit. I`m experimenting with placement of the sensor chip in various ferrite rings for better sensitivity. Here`s one example. 🔗 External reference

The ultra-sensitive gauss meter circuit is designed to detect magnetic fields with high sensitivity, utilizing a Hall effect sensor, which is a transducer that varies its output voltage in response to a magnetic field. The circuit typically includes a power supply section that provides the necessary voltage to the Hall sensor and other components. The Hall effect sensor generates a small voltage output, approximately 1.3mV per Gauss, which necessitates signal conditioning to amplify and filter this signal for practical use.

Signal conditioning may involve operational amplifiers to increase the output voltage, along with resistors and capacitors to form filters that eliminate noise and stabilize the output. This ensures that the small variations in voltage can be accurately interpreted by subsequent circuitry. A relay may be included in the design to act as a switch that activates or deactivates a load based on the detected magnetic field strength.

The choice of the Hall effect sensor integrated circuit is crucial, as its characteristics will determine the overall sensitivity and performance of the circuit. The circuit may be optimized by experimenting with the placement of the sensor within ferrite rings, which can enhance the magnetic field's strength at the sensor's location, thereby improving the sensitivity of the measurement.

While magneto-resistive and magneto-inductive sensors are alternatives used in applications like compasses, they are often more complex and less accessible than Hall effect sensors. The simplicity of the Hall effect sensor circuit makes it an attractive option for various applications, provided that the limitations of the sensor are understood and addressed. Overall, this circuit can serve as a foundational design for those seeking to create a sensitive magnetic field detection system with minimal complexity.An ultra sensitive gauss meter circuit/schematic anywhere that constitutes a simple indicator No measurement. No scaling. No accuracy. Just hall device/ic on a board with power supply inputs, a bit of signal conditioning of maybe a dozen more parts, and a little relay.

If you look at the linear hall effect sensor it has an output of 1. 3mV per Gauss. That might be the limitation of hall effect sensors in general which might be where all your problems are coming from. It`s got me wondering why you never see hall effect sensors in things like compasses. You always see some kind of magneto-resistive or magneto-inductive sensor for those kinds of things, but those are neither straightforward to work with, nor easily available. Is it possible to implement so simple a circuit Or are these merely rough application examples Sensitivity would only depend on the IC that is inserted, no I`m in the process of testing that last one and it may work for me.

But I`ve asked a few questions about it here and elsewhere and don`t seem to be making any headway. The simpler the better. I just want an ultra sensitive switch circuit. I`m experimenting with placement of the sensor chip in various ferrite rings for better sensitivity. Here`s one example. 🔗 External reference