TEMPERATURE REPORTING DIGITAL THERMOMETER

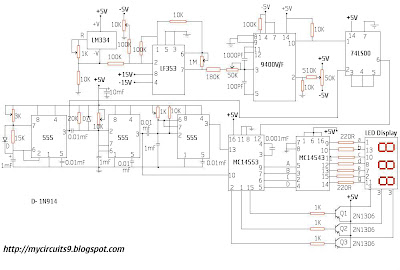

The ROMs or PROMs must contain the correct code for converting data from the NE5037, which serves as the address for the ROMs or PROMs, into the appropriate segment driver codes. The displayed temperature can be converted to degrees Fahrenheit (°F) by the controller, which operates within a range of 0 to 63 °F, or through the PROMs. To display temperatures exceeding 99 °F, a third digit (hundreds) PROM and display will be required. An expensive clock can be constructed using NAND gates or inverters as illustrated.

The circuit design involves the integration of read-only memory (ROM) or programmable read-only memory (PROM) modules that are essential for converting digital signals from the NE5037 temperature sensor. The NE5037 serves as an address line to access specific memory locations in the ROMs or PROMs, where the necessary conversion codes are stored. These codes are used to drive the segment display, which visually represents the temperature readings.

For temperatures ranging from 0 to 63 °F, the controller can directly utilize the output from the NE5037 to convert the sensor data into a readable format. However, when temperatures exceed 99 °F, an additional PROM must be incorporated to handle the hundreds digit. This additional component ensures that the display can accurately represent higher temperature values, thereby enhancing the system's functionality.

Furthermore, the design may include a timing mechanism, which could be realized using NAND gates or inverters. This clock circuitry is crucial for synchronizing operations within the system, ensuring that data is processed and displayed at the correct intervals. The use of NAND gates or inverters allows for a versatile and potentially cost-effective solution for generating clock signals, although the complexity of the circuit can increase based on the desired specifications and performance requirements.

Overall, the schematic will consist of the NE5037 interfacing with the ROMs or PROMs, the segment display for output, and the clock circuitry, all working in concert to provide accurate and timely temperature readings in degrees Fahrenheit. Proper attention to the logic design and component selection will ensure the reliability and efficiency of the temperature measurement system.The ROMs or PROMs must have the correct code for converting the data from the NE5037-used as address for the ROMs or PROMs-to the appropriate segment driver codes. The displayed amount could easily be converted to degrees Fahrenheit, °F, by the controller of (0 - 63 °temperature sensor) or through the (P) ROMs.

When doing this, a third (hundreds ) digit (P)ROM and display will be needed for displaying temperatures above 99 °F. An expensive clock can be made from NAND gates or inverters as shown. 🔗 External reference

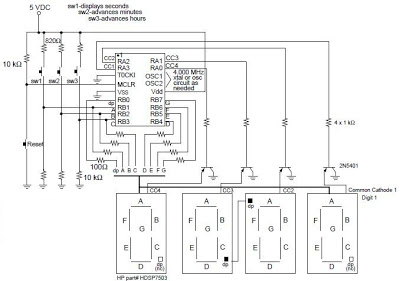

The circuit design involves the integration of read-only memory (ROM) or programmable read-only memory (PROM) modules that are essential for converting digital signals from the NE5037 temperature sensor. The NE5037 serves as an address line to access specific memory locations in the ROMs or PROMs, where the necessary conversion codes are stored. These codes are used to drive the segment display, which visually represents the temperature readings.

For temperatures ranging from 0 to 63 °F, the controller can directly utilize the output from the NE5037 to convert the sensor data into a readable format. However, when temperatures exceed 99 °F, an additional PROM must be incorporated to handle the hundreds digit. This additional component ensures that the display can accurately represent higher temperature values, thereby enhancing the system's functionality.

Furthermore, the design may include a timing mechanism, which could be realized using NAND gates or inverters. This clock circuitry is crucial for synchronizing operations within the system, ensuring that data is processed and displayed at the correct intervals. The use of NAND gates or inverters allows for a versatile and potentially cost-effective solution for generating clock signals, although the complexity of the circuit can increase based on the desired specifications and performance requirements.

Overall, the schematic will consist of the NE5037 interfacing with the ROMs or PROMs, the segment display for output, and the clock circuitry, all working in concert to provide accurate and timely temperature readings in degrees Fahrenheit. Proper attention to the logic design and component selection will ensure the reliability and efficiency of the temperature measurement system.The ROMs or PROMs must have the correct code for converting the data from the NE5037-used as address for the ROMs or PROMs-to the appropriate segment driver codes. The displayed amount could easily be converted to degrees Fahrenheit, °F, by the controller of (0 - 63 °temperature sensor) or through the (P) ROMs.

When doing this, a third (hundreds ) digit (P)ROM and display will be needed for displaying temperatures above 99 °F. An expensive clock can be made from NAND gates or inverters as shown. 🔗 External reference