The switching power supply for electrocar based on UC3842 is designed

The motor vehicle currently represents a no-emission automotive solution, serving as a green means of transportation that is expected to significantly impact human society in the 21st century. The direct-flow brushless electric machine has emerged as a leading technology and development direction in the field of electric machinery for motor vehicles. The performance of a brushless electric machine system is largely attributed to the effectiveness of its control module, which is heavily influenced by the characteristics of the electric power supply. Therefore, a high-quality power supply system plays a crucial role in the overall motor vehicle system. The control module of the direct-flow brushless electric machine is a numerically controlled electronic system utilizing a microcontroller. A switching power supply, managed by the UC3842 high-performance electric current mode PWM generator, is well-suited for this system. The design achieves complete isolation of input and output through a small-scale high-frequency voltage transformer, enhancing power efficiency, simplifying peripheral circuits, and reducing costs and size. The power supply features voltage stabilization with minimal ripple and reliable performance. The single-end anti-exciting type structure operates by utilizing the magnetic core of the voltage transformer solely on the collinear side of magnetic hysteresis. When the gas switching tube is activated, the energy stored in the primary coil is obstructed in the secondary winding. Conversely, when the gas switching tube is deactivated, the energy from the primary coil is released through the secondary winding. This design is a cost-effective solution that provides partial input/output isolation and improved voltage percentage modulation. The UC3842 chip, produced by Unitrode Company, is a high-performance, single-ended output electric current-controlled pulse width modulator. Its functional block diagram illustrates various components, including a 5V reference, duty ratio control, a comparator, a PWM latch, a high-gain error amplifier, and a high-current push-pull output circuit for driving power MOSFETs. The UC3842 chip achieves excellent electrical performance at a lower cost, making it widely used in low-powered switching power supplies ranging from 20 to 50 W. Key pin configurations include pin 8 for internal reference voltage (5V), pin 7 for power supply (operational voltage range 10-16V), pin 4 for the resonator, and pins 1 and 2 for compensating the opposite phase input of the internal voltage comparator. The chip generates a PWM signal at pin 6 to control the power device's switching. The current sensing mechanism at pin 3 measures input current, with a voltage exceeding 1V triggering the PWM pulse shutdown for current limiting protection. This text emphasizes the UC3842 as the central control unit in the design of the anti-exciting type stabilized voltage supply.

The described motor vehicle system employs a direct-flow brushless electric machine, which is a crucial component in the transition towards sustainable transportation. The brushless electric machine's efficiency is enhanced by the control module, which utilizes advanced microcontroller technology for precise operation. The integration of the UC3842 PWM generator allows for effective management of the switching power supply, ensuring that the energy conversion process is optimized for performance and reliability.

The high-frequency voltage transformer plays a vital role in isolating the input and output, which is essential for protecting sensitive components and ensuring stable operation. The transformer’s design not only improves efficiency but also minimizes the physical footprint of the power supply system, making it suitable for modern electric vehicles where space and weight are critical factors.

The UC3842 chip is notable for its versatile functionality, including the ability to handle varying load conditions while maintaining voltage regulation. Its architecture supports high-current applications, which is particularly important for electric vehicles that require significant power during acceleration and operation. The feedback mechanism employed within the chip allows for real-time adjustments to the PWM signal, ensuring that the motor operates within safe limits and enhancing the overall safety and longevity of the vehicle's electrical system.

In summary, the combination of a direct-flow brushless electric machine, a sophisticated control module utilizing the UC3842 PWM generator, and an efficient power supply with isolation features positions this motor vehicle solution as a leading example of modern electric vehicle technology. The emphasis on no emissions and energy efficiency aligns with global efforts to reduce environmental impact, making it a significant advancement in the automotive industry.The motor vehicle is the automotive of no emission at present, as the means of transportation of green, will bring the huge change to human society in the 21st century. And the direct-flow brushless electric machine relies on its fine characteristic to already become major technology and developing direction of the electrical machinery field of mo

tor vehicle. The of good performance brushless electric machine system is due to the of good performance control module, and the characteristic of the control module depends on the characteristic of the electric power supply to a great extent, so the high-quality power supply power system occupies quite important position in the whole motor vehicle system. The control module of the direct-flow brushless electric machine is a numerically controlled electronic system which adopts the microcontroller.

The switching power supply that is controlled on the basis of UC3842 high-performance electric current mode PWM generator is suitable for applying to this kind of system. Originally design realizing the complete segregation exported and input through the small-scale high-frequency voltage transformer, not only has raised the efficiency of the power, has simplified the peripheral circuit, also reduced cost and volume of the power.

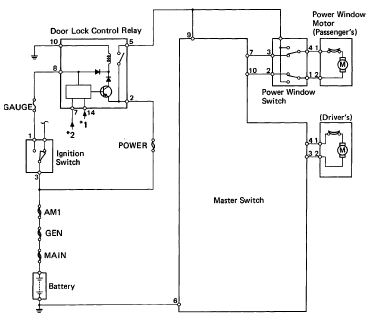

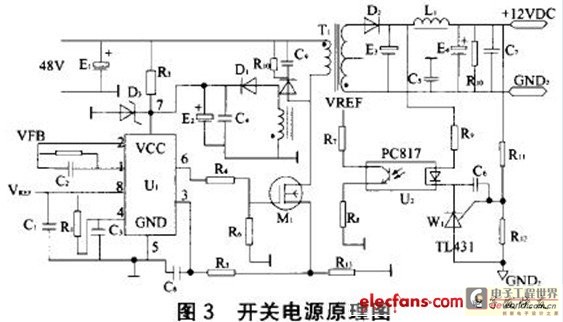

The voltage stabilization of power supply, the ripple is small, incessant, reliable performance. Single-end anti exciting type typical structure such as Fig. 1 of varying. Single-end means the magnetic core of the voltage transformer only works on the collinear side of magnetic Hysteresis; It means when the gas switching tube is turned on, the stored energy in the primary coil that anti exciting, and the secondary winding is obstructed; When the gas switching tube is shut off, the energy in the primary coil is released and supported through the secondary winding. This is a trimmer of a kind of low cost, can accomplish the partial complete segregation of Input/Output, there are better voltage percentage modulations.

UC3842 chip is the products of Unitrode Company, it is a kind of high-performance single-ended output type electric current controlled pulse width modulator chip. Their functional block diagrams are shown as in Fig. 2. By 5V reference, Shaker controlling the duty ratio to set up, determines comparator, PWM latch, high gain E/A error amplifier and is suitable for the high-current push pull output circuit of the propulsion power MOSFET etc.

to make up with electric current. Its leading particulars is: UC3842 chip can meet better electrical performance and lower cost at the same time, is widely used in the low-powered switching power supply of 20- 50 W. 8 feet are its internal reference voltage 5 V in the picture ; 7 feet are its end of power, the cut-in voltage of the chip work is 16V, the voltage of Under Voltage Lock Out is 10 V; 4 feet connect the resonator, produce the sawtooth wave of the required frequency, RT connects among 4, 8 feet, CT connects between 4 feet and ground.

1 and 2 feet, in order to compensate the oppisite phase input end of end and internal voltage comparator; Compare with voltage error signal of a foot from 3 foot incoming electric current feedback signals, produce one PWM puls e-width modulation The wave, from 6 feet Ausgang Output this signal, control the make-and-break of the power device. 3 feet measure the input end for the electric current. Because of set up the intersection of electric current and clamping of 1 V by the intersection of electric current and the intersection of comparator and input end, too big enabling the electric current sense resistor R13 shown as in Fig.

3 as electric current. The voltage had exceeds 1 V namely 3 foot level is greater than 1 V When, will shut off PWM pulse, thus will achieve the protective purpose of the current limiter. This text regards UC3842 as the key control unit, has designed the anti exciting type stabilized voltage s

🔗 External reference

The described motor vehicle system employs a direct-flow brushless electric machine, which is a crucial component in the transition towards sustainable transportation. The brushless electric machine's efficiency is enhanced by the control module, which utilizes advanced microcontroller technology for precise operation. The integration of the UC3842 PWM generator allows for effective management of the switching power supply, ensuring that the energy conversion process is optimized for performance and reliability.

The high-frequency voltage transformer plays a vital role in isolating the input and output, which is essential for protecting sensitive components and ensuring stable operation. The transformer’s design not only improves efficiency but also minimizes the physical footprint of the power supply system, making it suitable for modern electric vehicles where space and weight are critical factors.

The UC3842 chip is notable for its versatile functionality, including the ability to handle varying load conditions while maintaining voltage regulation. Its architecture supports high-current applications, which is particularly important for electric vehicles that require significant power during acceleration and operation. The feedback mechanism employed within the chip allows for real-time adjustments to the PWM signal, ensuring that the motor operates within safe limits and enhancing the overall safety and longevity of the vehicle's electrical system.

In summary, the combination of a direct-flow brushless electric machine, a sophisticated control module utilizing the UC3842 PWM generator, and an efficient power supply with isolation features positions this motor vehicle solution as a leading example of modern electric vehicle technology. The emphasis on no emissions and energy efficiency aligns with global efforts to reduce environmental impact, making it a significant advancement in the automotive industry.The motor vehicle is the automotive of no emission at present, as the means of transportation of green, will bring the huge change to human society in the 21st century. And the direct-flow brushless electric machine relies on its fine characteristic to already become major technology and developing direction of the electrical machinery field of mo

tor vehicle. The of good performance brushless electric machine system is due to the of good performance control module, and the characteristic of the control module depends on the characteristic of the electric power supply to a great extent, so the high-quality power supply power system occupies quite important position in the whole motor vehicle system. The control module of the direct-flow brushless electric machine is a numerically controlled electronic system which adopts the microcontroller.

The switching power supply that is controlled on the basis of UC3842 high-performance electric current mode PWM generator is suitable for applying to this kind of system. Originally design realizing the complete segregation exported and input through the small-scale high-frequency voltage transformer, not only has raised the efficiency of the power, has simplified the peripheral circuit, also reduced cost and volume of the power.

The voltage stabilization of power supply, the ripple is small, incessant, reliable performance. Single-end anti exciting type typical structure such as Fig. 1 of varying. Single-end means the magnetic core of the voltage transformer only works on the collinear side of magnetic Hysteresis; It means when the gas switching tube is turned on, the stored energy in the primary coil that anti exciting, and the secondary winding is obstructed; When the gas switching tube is shut off, the energy in the primary coil is released and supported through the secondary winding. This is a trimmer of a kind of low cost, can accomplish the partial complete segregation of Input/Output, there are better voltage percentage modulations.

UC3842 chip is the products of Unitrode Company, it is a kind of high-performance single-ended output type electric current controlled pulse width modulator chip. Their functional block diagrams are shown as in Fig. 2. By 5V reference, Shaker controlling the duty ratio to set up, determines comparator, PWM latch, high gain E/A error amplifier and is suitable for the high-current push pull output circuit of the propulsion power MOSFET etc.

to make up with electric current. Its leading particulars is: UC3842 chip can meet better electrical performance and lower cost at the same time, is widely used in the low-powered switching power supply of 20- 50 W. 8 feet are its internal reference voltage 5 V in the picture ; 7 feet are its end of power, the cut-in voltage of the chip work is 16V, the voltage of Under Voltage Lock Out is 10 V; 4 feet connect the resonator, produce the sawtooth wave of the required frequency, RT connects among 4, 8 feet, CT connects between 4 feet and ground.

1 and 2 feet, in order to compensate the oppisite phase input end of end and internal voltage comparator; Compare with voltage error signal of a foot from 3 foot incoming electric current feedback signals, produce one PWM puls e-width modulation The wave, from 6 feet Ausgang Output this signal, control the make-and-break of the power device. 3 feet measure the input end for the electric current. Because of set up the intersection of electric current and clamping of 1 V by the intersection of electric current and the intersection of comparator and input end, too big enabling the electric current sense resistor R13 shown as in Fig.

3 as electric current. The voltage had exceeds 1 V namely 3 foot level is greater than 1 V When, will shut off PWM pulse, thus will achieve the protective purpose of the current limiter. This text regards UC3842 as the key control unit, has designed the anti exciting type stabilized voltage s

🔗 External reference