USB I2C Interface

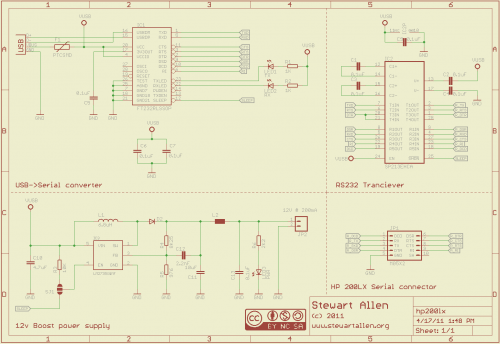

This kit is based on an original design by Jan G0BBL and serves as a versatile replacement for the older "Rocky" serial interface kit. It includes control of the programmable oscillator on the V6, 3 RXTX (and the older, now retired Lite + Xtrall V8.3 RX) kits, over a USB cable using the I2C protocol with two serial streams: the clock stream (SCL) and the data stream (SDA). With the appropriate software drivers, this kit eliminates the 16 frequency limitation of the RX V8.3 and RXTX V6.3 kits. For detailed information regarding the firmware and its capabilities/configuration, refer to Bob G8VOI's User Manual and Fred PE0FKO's configuration manual. It is advisable to access and download relevant sections of these guides to assist with the setup during the final phase of this build. Builders should read each page thoroughly, ensuring to compare the "bare board" photos with the completed stage photos before commencing actual construction. For less experienced builders, this site provides a step-by-step guide through the kit assembly. Each stage is self-contained and outlines the necessary steps to build and test that stage, significantly increasing the likelihood of success in the final assembly, as each preceding stage will have been built and tested. For those who may not be adept at soldering, Tom N0SS's tutorial on basic soldering techniques is highly recommended. For those looking for a more advanced approach, a reflow process using solder paste and an electric oven can be utilized to install all SMT chips on one side of the PCB. This method is documented by Guenael Jouchet in a YouTube segment. A well-lit workspace and a minimum of 3X magnification are essential; the author uses a low-cost magnifying fluorescent light with a 3X lens, supplemented by a hand-held 10X loupe with light for close inspection of solder joints and SMT installation. It is advisable to use a cookie sheet or baking pan with raised edges as a work surface to catch stray parts, particularly tiny SMT chips, which can be difficult to locate if lost. Solidly clamping the PCB in a holder while soldering is crucial. A "third-hand" tool, such as a Panavise or Hendricks kits PCB Vise, can hold the board during soldering. A simple third-hand alligator clip vise can suffice in a pinch. Jan G0BBL suggests a cost-effective method of securing the PCB by screwing a large document clip to a wood block, which can clamp the side of the PCB. Each stage will include a "Testing" section outlining one or more tests that, when successfully completed, provide confidence that the assembly is progressing correctly toward a fully tested and built transceiver. Results of tests should be recorded in the designated area of the Testing section, facilitating troubleshooting via the reflector, as communication with experts will utilize a standard testing and measurement regime. Builders should be aware that actual measurements may vary by as much as +/- 10% from the expected values provided. These expected/nominal measurement values serve as a guideline to help builders assess the success of their tests. Any concerns regarding measurements should be communicated as queries in the Softrock reflector for expert assistance. A meticulous inspection of the assembly should always precede testing, utilizing the best lighting available.

This electronic kit offers a robust solution for enthusiasts looking to upgrade their serial interface capabilities while providing a comprehensive guide for assembly and testing. The integration of I2C protocol facilitates efficient communication between components, enhancing the overall functionality of the system. The step-by-step assembly instructions are designed to cater to a range of skill levels, ensuring that both novice and experienced builders can successfully complete the project. The emphasis on thorough testing and documentation fosters a systematic approach to troubleshooting, which is essential in the realm of electronics where precision is paramount. The inclusion of advanced soldering techniques and methods such as the reflow process demonstrates a commitment to modern assembly practices, catering to a diverse audience of builders. Overall, this kit not only serves as a practical tool for interfacing but also as an educational resource, empowering builders with the knowledge and skills necessary for successful electronic assembly.This kit is based upon an original design by Jan G0BBL and provides a multi-faceted replacement for the older "Rocky" serial interface kit. The kit includes: The control of the programmable Oscillator on the V6. 3 RXTX (and the older, now retired Lite + Xtrall V8. 3 RX) kits, over a USB cable, using the I2C protocol of two serial streams (the clocki ng stream, named "SCL", and the data stream, named "SDA"). With the proper software drivers, this kit removes the 16 frequency constraint of the RX V8. 3 and RXTX V6. 3 kits For more information on the firmware and its capabilities/configuration, refer to Bob G8VOI`s Users Manual and Fred PE0FKO`s configuration manual. You should access and download relevant portions of these guides to assist you with the setup in the final phase of this build.

The builder should read each page completely, taking care to compare the "bare board" photos with the completed stage photos, before undertaking actual construction. For the non-expert builders among us, this site takes you through a stage-by-stage build of the kit. Each stage is self-contained and outlines the steps to build and test the stage. This ensures that you will have a much better chance of success once you reach the last step, since you will have successfully built and tested each preceding stage before moving on to the next stage.

If you are not experienced at soldering (and even if you are somewhat experienced at soldering), refer to Tom N0SS`s excellent tutorial on basic soldering techniques. For the more adventurous, there is a process using solder paste and an electric oven called the reflow process, which can be used to install all the SMT chips to one side of the PC Board.

This is documented by Guenael Jouchet in the following Youtube segment: You will need a well-lit work area and a minimum of 3X magnification (the author uses a cheap magnifying fluorescent light with a 3X lens. This is supplemented by a hand-held 10 X loupe - with light - for close-in inspection of solder joints and SMT installation.

You should use a cookie sheet or baking pan (with four sides raised approximately a half an inch) for your actual work space. It is highly recommended for building on top of in order to catch stray parts, especially the tiny SMT chips which, once they are launched by an errant tweezer squeeze, are nigh on impossible to find if they are not caught on the cookie sheet.

It is most important to solidly clamp the PCB in a holder when soldering. A "third-hand" (e. g. , Panavise or the Hendricks kits PCB Vise ) can hold your board while soldering. In a pinch, you can get by with a simple third-hand, alligator clip vise. Jan G0BBL suggests "A very cheap way is to screw a Large Document Clip to a woodblock which will clamp the side of a PCB. " Each stage will have a "Testing" Section, outlining one or more tests that, when successfully completed, provide you with the confidence and assurance that you are heading in the right direction towards a fully tested and built transceiver.

When you perform a test, you should always record the results of the test where indicated in the Testing section. This will make troubleshooting via the reflector much easier, since you will be communicating with the experts using a standard testing and measurement regime.

When comparing measurements to those published in these notes, the builder should be aware that actual and expected values could vary by as much as +/- 10%. The idea behind furnishing "expected/nominal" measurement values is to provide the builder with a good, "ballpark" number to determine whether or not the test has been successful.

If the builder has concerns about his measurements, he should by all means pose those concerns as a query in the Softrock reflector so the experts can provide assistance. It goes without saying that you should ALWAYS precede any tests with a very careful, minute inspection (using the best light and

🔗 External reference

This electronic kit offers a robust solution for enthusiasts looking to upgrade their serial interface capabilities while providing a comprehensive guide for assembly and testing. The integration of I2C protocol facilitates efficient communication between components, enhancing the overall functionality of the system. The step-by-step assembly instructions are designed to cater to a range of skill levels, ensuring that both novice and experienced builders can successfully complete the project. The emphasis on thorough testing and documentation fosters a systematic approach to troubleshooting, which is essential in the realm of electronics where precision is paramount. The inclusion of advanced soldering techniques and methods such as the reflow process demonstrates a commitment to modern assembly practices, catering to a diverse audience of builders. Overall, this kit not only serves as a practical tool for interfacing but also as an educational resource, empowering builders with the knowledge and skills necessary for successful electronic assembly.This kit is based upon an original design by Jan G0BBL and provides a multi-faceted replacement for the older "Rocky" serial interface kit. The kit includes: The control of the programmable Oscillator on the V6. 3 RXTX (and the older, now retired Lite + Xtrall V8. 3 RX) kits, over a USB cable, using the I2C protocol of two serial streams (the clocki ng stream, named "SCL", and the data stream, named "SDA"). With the proper software drivers, this kit removes the 16 frequency constraint of the RX V8. 3 and RXTX V6. 3 kits For more information on the firmware and its capabilities/configuration, refer to Bob G8VOI`s Users Manual and Fred PE0FKO`s configuration manual. You should access and download relevant portions of these guides to assist you with the setup in the final phase of this build.

The builder should read each page completely, taking care to compare the "bare board" photos with the completed stage photos, before undertaking actual construction. For the non-expert builders among us, this site takes you through a stage-by-stage build of the kit. Each stage is self-contained and outlines the steps to build and test the stage. This ensures that you will have a much better chance of success once you reach the last step, since you will have successfully built and tested each preceding stage before moving on to the next stage.

If you are not experienced at soldering (and even if you are somewhat experienced at soldering), refer to Tom N0SS`s excellent tutorial on basic soldering techniques. For the more adventurous, there is a process using solder paste and an electric oven called the reflow process, which can be used to install all the SMT chips to one side of the PC Board.

This is documented by Guenael Jouchet in the following Youtube segment: You will need a well-lit work area and a minimum of 3X magnification (the author uses a cheap magnifying fluorescent light with a 3X lens. This is supplemented by a hand-held 10 X loupe - with light - for close-in inspection of solder joints and SMT installation.

You should use a cookie sheet or baking pan (with four sides raised approximately a half an inch) for your actual work space. It is highly recommended for building on top of in order to catch stray parts, especially the tiny SMT chips which, once they are launched by an errant tweezer squeeze, are nigh on impossible to find if they are not caught on the cookie sheet.

It is most important to solidly clamp the PCB in a holder when soldering. A "third-hand" (e. g. , Panavise or the Hendricks kits PCB Vise ) can hold your board while soldering. In a pinch, you can get by with a simple third-hand, alligator clip vise. Jan G0BBL suggests "A very cheap way is to screw a Large Document Clip to a woodblock which will clamp the side of a PCB. " Each stage will have a "Testing" Section, outlining one or more tests that, when successfully completed, provide you with the confidence and assurance that you are heading in the right direction towards a fully tested and built transceiver.

When you perform a test, you should always record the results of the test where indicated in the Testing section. This will make troubleshooting via the reflector much easier, since you will be communicating with the experts using a standard testing and measurement regime.

When comparing measurements to those published in these notes, the builder should be aware that actual and expected values could vary by as much as +/- 10%. The idea behind furnishing "expected/nominal" measurement values is to provide the builder with a good, "ballpark" number to determine whether or not the test has been successful.

If the builder has concerns about his measurements, he should by all means pose those concerns as a query in the Softrock reflector so the experts can provide assistance. It goes without saying that you should ALWAYS precede any tests with a very careful, minute inspection (using the best light and

🔗 External reference