Water AlarmCircuit

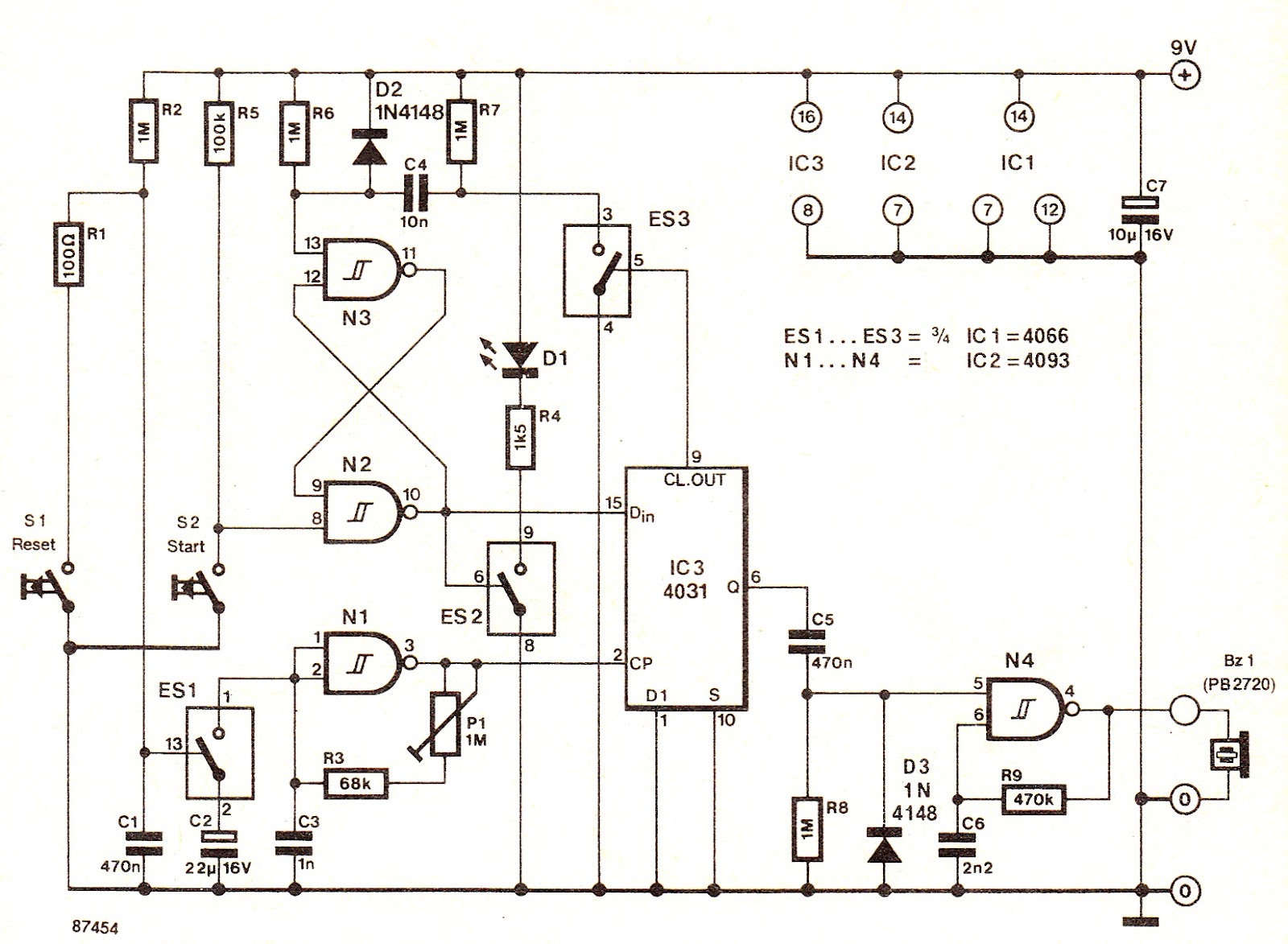

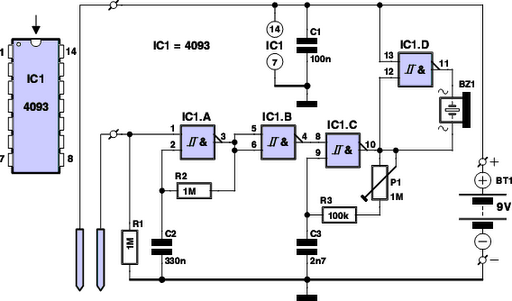

Have you ever observed the stairs to an upper story in your house transform into a waterfall? Or perhaps you returned home to find your aquarium fish attempting to swim across the carpet? For your sake, it is hoped that such scenarios have not occurred, as the consequences are typically quite severe. With a few electronic components, it is possible to ensure that you receive a warning before needing to don waders. Preventing water issues is preferable to addressing them after the fact. Nevertheless, despite taking numerous precautions, occasional leaks can still occur. A burst water supply hose from the washing machine, a bath tap left running, a broken aquarium wall, or a leaking boiler or central heating tank—anything is possible. In such instances, receiving a prompt warning, such as from an acoustic water alarm, can help mitigate damage. For those proficient with a soldering iron and familiar with the distinction between an IC and a PC, building the electronic water alarm described here can be an enjoyable project. The circuit leverages the fact that normal water is always slightly contaminated and thus conducts electricity to a certain degree. It is constructed around a popular integrated circuit from the older 4000-series logic family: the 4093. This IC features four inverted-output AND gates (NAND gates) with Schmitt-trigger inputs. When water is detected between the probes, it emits an intermittent and somewhat annoying beeping tone. The water's conductivity activates the circuit centered around IC1a. The two electrodes (probes) should be positioned at the lowest point where water might accumulate. These can be two tinned copper wires or two pieces of circuit board with the copper surface coated in solder. The combination of IC1a, resistor R2, and capacitor C2 forms a simple oscillator that produces the intermittent alarm effect. When no water is present between the probes, R1 holds the input of IC1a low, resulting in a low output from IC1b, and the oscillator remains inactive. However, when moisture is detected, the supply voltage elevates input 1 of gate IC1a high through the conductive water, prompting the gate to begin oscillating. When the output of IC1b is high, the tone generator built around IC1c is activated, energizing buzzer BZ1. This results in a periodic, intermittent beeping tone. The intermittent sound effect of the water alarm can be adjusted to personal preference by modifying the values of R2 or C2. Additionally, the pitch of the sound can be altered using P1; the closer the pitch is to the resonant frequency of buzzer BZ1, the louder the tone will be. It is advisable to set the sound to the most irritating level possible. Gate IC1d serves to amplify the power supplied to the buzzer by inverting the output signal from IC1c, effectively doubling the voltage applied to the buzzer. The alarm circuit should be installed in a location that remains dry. A pair of thin twisted wires should connect the electrodes (probes) to the board; insulated, flexible wire should be used for this purpose. Twisting the wires together reduces the sensitivity of the relatively long connection between the probes and the circuit to false alarms caused by external electromagnetic interference. The current consumption is very low (less than 0.1 µA) when the environment is dry. When the buzzer is activated, current consumption can increase to around 2 mA, with measurements reaching 3 mA at the maximum frequency setting. Consequently, the battery can last for several years as long as no water is detected. However, it is important to consider that the battery may begin to leak over time.

The electronic water alarm circuit employs a 4093 IC, which is a quad 2-input NAND gate with Schmitt-trigger inputs, ensuring reliable operation in the presence of noise and fluctuations in the signal. The circuit uses two probes that serve as electrodes, which are strategically placed at the lowest point where water may accumulate. When water bridges the gap between the probes, it completes the circuit, allowing current to flow through the conductive water and triggering the oscillator circuit formed by the combination of IC1a, R2, and C2.

The oscillator generates a square wave signal that drives the buzzer, producing an audible alert. The frequency of the oscillation can be adjusted by modifying the values of R2 and C2, allowing for customization of the alarm's sound to suit user preferences. The pitch can also be fine-tuned using a potentiometer (P1), enhancing the effectiveness of the alert by ensuring it is loud and attention-grabbing.

IC1d functions as a power amplifier, increasing the voltage supplied to the buzzer, which results in a more pronounced audio signal. This is crucial for ensuring that the alarm is heard in various environments. The use of insulated and twisted wires for the probe connections minimizes the risk of false alarms due to electromagnetic interference from nearby electronic devices.

The low current consumption of the circuit when idle ensures that the battery life is extended, making this water alarm a practical solution for early leak detection in residential and commercial settings. Regular maintenance and monitoring of the battery are recommended to prevent leakage and ensure continued operation of the alarm system.Have you ever seen the stairs to one of the upper stories in your house turn into a waterfall Or maybe you`ve come home to find your aquarium fish trying to swim across the carpet For your sake, we hope not, because the consequences are usually fairly dramatic. With a handful of electronic components, you can at least ensure that you will be war ned before you have to put on your waders. It`s better to prevent water problems than to have to correct them. But no how many precautions you take, an occasional leak can still happen. A burst water supply hose for the washing machine, a bath tap that someone forgot to turn off, a broken aquarium wall, or a leaking boiler or central heating tank anything is possible. In such cases, it`s nice to be warned as quickly as possible, for example by an acoustic water alarm.

Then you can at least limit the damage. If you`re handy with a soldering iron and know the difference between an IC and a PC, you`ll no doubt enjoy building the electronic water alarm described here. The circuit takes advantage of the fact that normal` water is always slightly contaminated, even if only slightly, and thus conducts electricity to a certain extent.

It is built around an popular IC from the somewhat antiquated 4000-series logic family: the 4093. This IC contains four inverted-output AND gates (NAND gates) with Schmitt-trigger inputs. If water is detected between the probes, it emits an intermittent and rather irritating beeping tone. The conductivity of the water is used to active the circuit built around IC1a. The two electrodes (probes) are fitted at the lowest point where water will come to stand. They can be two tinned copper wires, but you can also use two pieces of circuit board with the copper surface coated with solder.

The combination of IC1a, resistor R2 and capacitor C2 forms a simple oscillator that produces the intermittent (on/off) effect of the alarm. If no water is present between the probes, the input of IC1a is held low by R1 and the output of IC1b is also low.

The oscillator is not active in this state. If moisture is sensed, the supply voltage pulls input 1 of gate IC1a high via the conductive water, causing the gate to start oscillating. Whenever the output of IC1b is high, the tone generator built around IC1c is enabled, and in turn it energizes buzzer BZ1.

The net result is a periodic, intermittent beeping tone. You can adjust the intermittent effect of the sound produced by the water alarm to suit your taste by simply adjusting the value of R2 or C2. You can also set the pitch of the sound with P1. The closer the pitch is to the resonant frequency of buzzer BZ1, the louder the tone will be. You should set the sound to the most irritating level possible. Gate IC1d is used to boost the amount of power than can be pumped into the buzzer. It inverts the output signal from IC1c to double the voltage applied to the buzzer. Naturally, the circuit of the alarm must be fitted somewhere that will remain high and dry. Use a pair of thin twisted wires to connect the electrodes (probes) to the board. Naturally, you should use insulated, flexible wire for this purpose. Twisting the wires together makes the relatively long connection between the probes and the circuit less sensitive to false alarms due to external electromagnetic interference.

The current consumption is very low (less than 0. 1 µA) when everything is dry. When the buzzer is energized, the current consumption can rise to around 2mA. We measured 3mA with the frequency set to the maximum value. The battery will thus last for several years as long as no water is detected. Of course, you should bear in mind that the battery might start leaking after a while 🔗 External reference

The electronic water alarm circuit employs a 4093 IC, which is a quad 2-input NAND gate with Schmitt-trigger inputs, ensuring reliable operation in the presence of noise and fluctuations in the signal. The circuit uses two probes that serve as electrodes, which are strategically placed at the lowest point where water may accumulate. When water bridges the gap between the probes, it completes the circuit, allowing current to flow through the conductive water and triggering the oscillator circuit formed by the combination of IC1a, R2, and C2.

The oscillator generates a square wave signal that drives the buzzer, producing an audible alert. The frequency of the oscillation can be adjusted by modifying the values of R2 and C2, allowing for customization of the alarm's sound to suit user preferences. The pitch can also be fine-tuned using a potentiometer (P1), enhancing the effectiveness of the alert by ensuring it is loud and attention-grabbing.

IC1d functions as a power amplifier, increasing the voltage supplied to the buzzer, which results in a more pronounced audio signal. This is crucial for ensuring that the alarm is heard in various environments. The use of insulated and twisted wires for the probe connections minimizes the risk of false alarms due to electromagnetic interference from nearby electronic devices.

The low current consumption of the circuit when idle ensures that the battery life is extended, making this water alarm a practical solution for early leak detection in residential and commercial settings. Regular maintenance and monitoring of the battery are recommended to prevent leakage and ensure continued operation of the alarm system.Have you ever seen the stairs to one of the upper stories in your house turn into a waterfall Or maybe you`ve come home to find your aquarium fish trying to swim across the carpet For your sake, we hope not, because the consequences are usually fairly dramatic. With a handful of electronic components, you can at least ensure that you will be war ned before you have to put on your waders. It`s better to prevent water problems than to have to correct them. But no how many precautions you take, an occasional leak can still happen. A burst water supply hose for the washing machine, a bath tap that someone forgot to turn off, a broken aquarium wall, or a leaking boiler or central heating tank anything is possible. In such cases, it`s nice to be warned as quickly as possible, for example by an acoustic water alarm.

Then you can at least limit the damage. If you`re handy with a soldering iron and know the difference between an IC and a PC, you`ll no doubt enjoy building the electronic water alarm described here. The circuit takes advantage of the fact that normal` water is always slightly contaminated, even if only slightly, and thus conducts electricity to a certain extent.

It is built around an popular IC from the somewhat antiquated 4000-series logic family: the 4093. This IC contains four inverted-output AND gates (NAND gates) with Schmitt-trigger inputs. If water is detected between the probes, it emits an intermittent and rather irritating beeping tone. The conductivity of the water is used to active the circuit built around IC1a. The two electrodes (probes) are fitted at the lowest point where water will come to stand. They can be two tinned copper wires, but you can also use two pieces of circuit board with the copper surface coated with solder.

The combination of IC1a, resistor R2 and capacitor C2 forms a simple oscillator that produces the intermittent (on/off) effect of the alarm. If no water is present between the probes, the input of IC1a is held low by R1 and the output of IC1b is also low.

The oscillator is not active in this state. If moisture is sensed, the supply voltage pulls input 1 of gate IC1a high via the conductive water, causing the gate to start oscillating. Whenever the output of IC1b is high, the tone generator built around IC1c is enabled, and in turn it energizes buzzer BZ1.

The net result is a periodic, intermittent beeping tone. You can adjust the intermittent effect of the sound produced by the water alarm to suit your taste by simply adjusting the value of R2 or C2. You can also set the pitch of the sound with P1. The closer the pitch is to the resonant frequency of buzzer BZ1, the louder the tone will be. You should set the sound to the most irritating level possible. Gate IC1d is used to boost the amount of power than can be pumped into the buzzer. It inverts the output signal from IC1c to double the voltage applied to the buzzer. Naturally, the circuit of the alarm must be fitted somewhere that will remain high and dry. Use a pair of thin twisted wires to connect the electrodes (probes) to the board. Naturally, you should use insulated, flexible wire for this purpose. Twisting the wires together makes the relatively long connection between the probes and the circuit less sensitive to false alarms due to external electromagnetic interference.

The current consumption is very low (less than 0. 1 µA) when everything is dry. When the buzzer is energized, the current consumption can rise to around 2mA. We measured 3mA with the frequency set to the maximum value. The battery will thus last for several years as long as no water is detected. Of course, you should bear in mind that the battery might start leaking after a while 🔗 External reference