X-10 Ninja Pan and Tilt Modifications

This is a 16x2 switcher, providing ample room for expansion. While the cameras are satisfactory, the primary requirement was the capability to pan and tilt the selected cameras to adjust the view as needed. Extensive research revealed that most pan and tilt mounts were priced higher than acceptable. Although building a custom solution was feasible, it involved more packaging complexity than desired. The Ninja Pan and Tilt Camera Mounts from X-10 were ultimately chosen due to their affordability, with the last unit purchased for $30 on eBay, and they appeared to be reasonably well-constructed. However, these mounts are controlled via an RF remote, which has a limited range, making them less appealing since the cameras are distributed over a wider area and control was intended from a home control system located in the basement. Numerous online resources discuss hacking these devices, primarily focusing on enhancing remote range. Some enthusiasts have even replaced the processor in the Ninja with their own custom code. Given that the cameras are hard-wired, a hard-wired solution for the Ninja was preferred, converting it to operate on an RS-485 network. This document outlines that process. Extensive information was found online, with the most pertinent details regarding the Ninja protocol sourced from Ed Cheung's comprehensive home automation site and Dave Houston's excellent website. The final modification involved replacing the microcontroller with an SX controller, enabling control over a serial link to a PC, alongside a new protocol and additional capabilities. However, controlling multiple Ninjas presented a challenge due to the distance limitations of an RS-232 connection. The accompanying images depict the PCB, main processor, the 5V regulator, and the ribbon cables supplying power signals to the servos located beneath the PCB. Another image shows the RF receiver board responsible for receiving the RF signal and transmitting it to the main processor. This board has three wires connecting it to the main board: the white and black wires for +5V and Ground, respectively, and a yellow wire that serves as the signal to the main processor. As RF communication is not being utilized, this board will be removed, and a new interface will be designed to fit in the same location using the existing wires, ensuring the processor remains unaware of the change. Prior to complete removal, the wire was cut to inspect the signal sent to the Ninja processor using a Logic Analyzer from Saleae LLC, a valuable tool for understanding circuit operations and programming. Upon connecting the analyzer to the yellow signal wire, significant data was obtained. The decision was made to replace the RF board with a custom board utilizing an Atmel ATTiny2313 AVR controller, which has proven reliable over time. Although programming can be done in assembler, Bascom-AVR is typically preferred for its efficiency and speed. To ensure replication of the Ninja protocol, a Tiny2313 was installed on a breadboard.

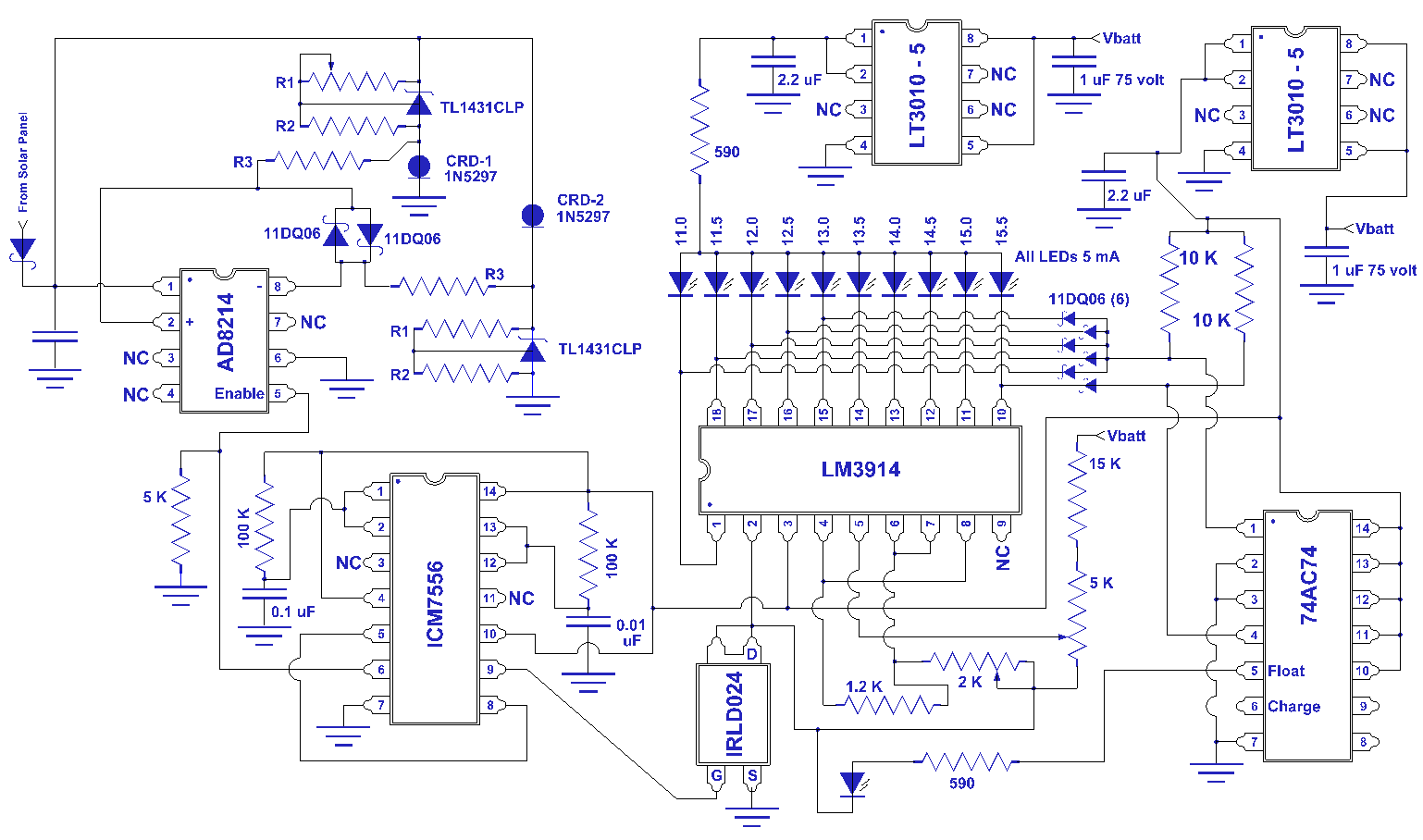

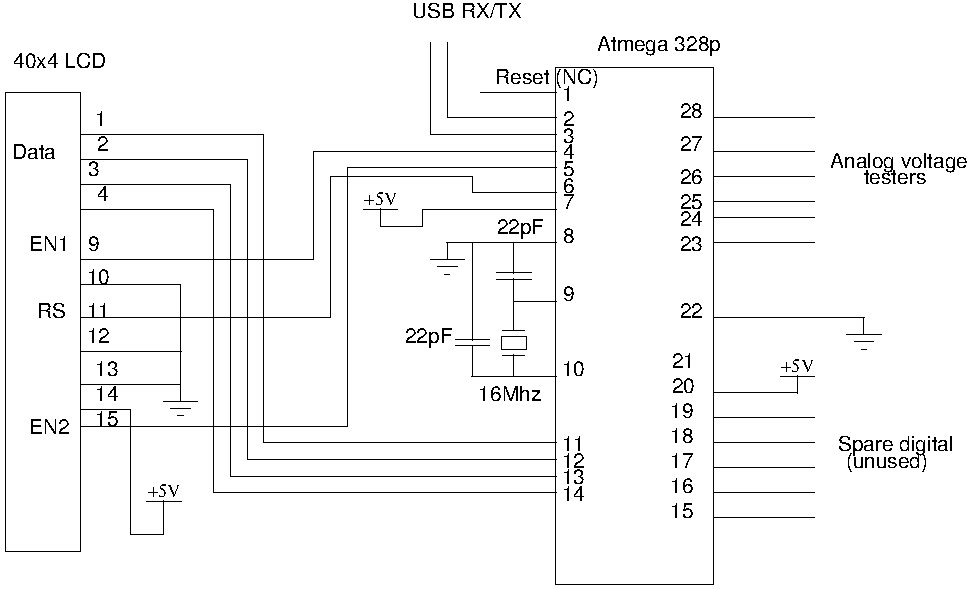

The circuit design involves a 16x2 switcher configuration, allowing for the connection of multiple cameras and facilitating their control through a centralized system. The primary focus is on the development of a hard-wired control mechanism utilizing RS-485 communication, which is well-suited for long-distance data transmission. The Ninja Pan and Tilt mounts will be modified to incorporate the ATTiny2313 microcontroller, which will manage the pan and tilt functions through a serial interface. This approach allows for real-time control of multiple cameras without the limitations associated with RF communication.

The schematic will illustrate the connections between the ATTiny2313, the servos responsible for the pan and tilt movements, and the power supply circuitry. The existing RF receiver board will be replaced with a custom circuit that interfaces directly with the ATTiny2313, ensuring that the microcontroller receives the necessary signals to control the servos accurately. The power supply section will include a 5V regulator to provide stable voltage to the microcontroller and servos.

In summary, this project aims to enhance the functionality of the Ninja Pan and Tilt Camera Mounts by implementing a hard-wired RS-485 communication system, allowing for improved control and expanded capabilities while maintaining compatibility with existing hardware. The use of the ATTiny2313 microcontroller will facilitate the execution of complex control algorithms and ensure reliable performance across multiple camera units.This is a 16X2 switcher so it gives me plenty of room for expansion. While the cameras are nice, what I really wanted was the ability to pan and tilt selected cameras to change the view if necessary. I did quite a bit of searching and most of the pan and tilt mounts were more than I was willing to pay.

I also considered building my own but, while doable, was more packaging than I wanted to mess with. I finally settled on the Ninja Pan and Tilt Camera Mounts from X-10. These are relatively inexpensive - I got my last one on eBay for $30 - and appear to be reasonably well built. The negative to these mounts, at least for me, is that they are controlled by an RF remote and the knock on them is that they have a pretty limited range.

My cameras tend to be spread out and I wanted to control them from my home control system located in the basement so that didn`t seem to be a very attractive option. There are quite a few sites around the internet devoted to hacking these devices but most of them seem to be aimed at increasing the range of the remotes.

There`s even a few where someone has replaced the processor in the Ninja with their own processor and custom code. Since my cameras are all hard-wired, I decided to go with a hard-wired approach for the Ninja as well and convert them to operate an an RS-485 network.

That`s what this page is all about. As I mentioned previously, there is quite a bit of information available on the web and the most important piece of information I needed was the protocol currently used by the Ninja. I found the best descriptions on Ed Cheungs comprehensive home automation site (although the data was actually provided by Dennis Hawkins) and Dave Houston`s excellent web site.

I also found all of the details of how the Ninja hardware worked on this site. This last modification consisted of replacing the micrcontroller with an SX controller and changed the Ninja to be controlled over a serial link to a PC. It also involved a new protocol and several new capabilities. While I liked this approach, I wanted to control several Ninjas and the distance would just be too great for an RS-232 connection.

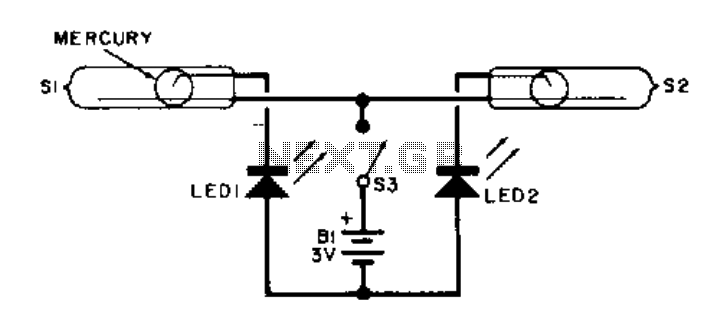

So let`s get started. In the shot on the left you can see the PCB, main processor, the 5 volt regulator under the mess of wiring, and the ribbon cables which supply the power signals to the servos located under the PCB. In the shot on the right you can see the RF receiver board which is responsible for receiving the RF signal and transmitting it to the main processor.

This board has 3 wires connecting it to the main board - the white and black wires which are +5V and Ground as well as the yellow wire which is the signal to the main processor. Since we are not using RF, we will remove this board and then design our new interface to fit in the same location using the same wires.

If we do this correctly, the processor will never know the difference. Before removing the board completely, I cut the wire to get a better look at the signal going to the Ninja processor. In order to see this, I used my Logic Analyzer from Saleae LLC. This is a great product at a great price and, if you`ve never used one before, it`s a great tool for understanding whats going on with your circuits and programming.

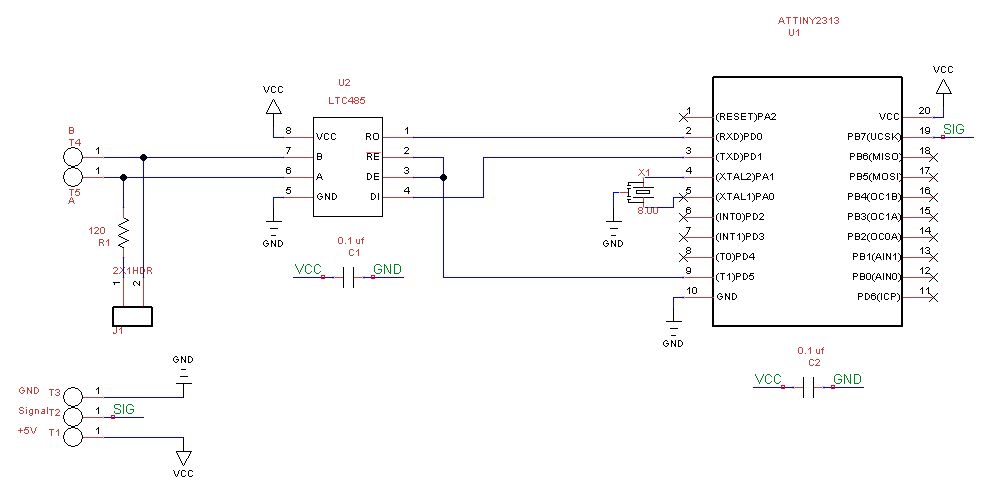

So when I hooked up the analyzer to the yellow signal wires, here`s what I got: My choice was to replace the RF board with my own board using an Atmel ATTiny2313 AVR controller. I`ve been using Atmel processors for a while now and am very pleased with their performance and, while I can program them in assembler, I usually choose Bascom-AVR.

This is a very nice Basic compiler and produces excellent and fast code. In order to make sure that I could replicate the Ninja protocol, I installed a Tiny2313 on my breadboard 🔗 External reference

The circuit design involves a 16x2 switcher configuration, allowing for the connection of multiple cameras and facilitating their control through a centralized system. The primary focus is on the development of a hard-wired control mechanism utilizing RS-485 communication, which is well-suited for long-distance data transmission. The Ninja Pan and Tilt mounts will be modified to incorporate the ATTiny2313 microcontroller, which will manage the pan and tilt functions through a serial interface. This approach allows for real-time control of multiple cameras without the limitations associated with RF communication.

The schematic will illustrate the connections between the ATTiny2313, the servos responsible for the pan and tilt movements, and the power supply circuitry. The existing RF receiver board will be replaced with a custom circuit that interfaces directly with the ATTiny2313, ensuring that the microcontroller receives the necessary signals to control the servos accurately. The power supply section will include a 5V regulator to provide stable voltage to the microcontroller and servos.

In summary, this project aims to enhance the functionality of the Ninja Pan and Tilt Camera Mounts by implementing a hard-wired RS-485 communication system, allowing for improved control and expanded capabilities while maintaining compatibility with existing hardware. The use of the ATTiny2313 microcontroller will facilitate the execution of complex control algorithms and ensure reliable performance across multiple camera units.This is a 16X2 switcher so it gives me plenty of room for expansion. While the cameras are nice, what I really wanted was the ability to pan and tilt selected cameras to change the view if necessary. I did quite a bit of searching and most of the pan and tilt mounts were more than I was willing to pay.

I also considered building my own but, while doable, was more packaging than I wanted to mess with. I finally settled on the Ninja Pan and Tilt Camera Mounts from X-10. These are relatively inexpensive - I got my last one on eBay for $30 - and appear to be reasonably well built. The negative to these mounts, at least for me, is that they are controlled by an RF remote and the knock on them is that they have a pretty limited range.

My cameras tend to be spread out and I wanted to control them from my home control system located in the basement so that didn`t seem to be a very attractive option. There are quite a few sites around the internet devoted to hacking these devices but most of them seem to be aimed at increasing the range of the remotes.

There`s even a few where someone has replaced the processor in the Ninja with their own processor and custom code. Since my cameras are all hard-wired, I decided to go with a hard-wired approach for the Ninja as well and convert them to operate an an RS-485 network.

That`s what this page is all about. As I mentioned previously, there is quite a bit of information available on the web and the most important piece of information I needed was the protocol currently used by the Ninja. I found the best descriptions on Ed Cheungs comprehensive home automation site (although the data was actually provided by Dennis Hawkins) and Dave Houston`s excellent web site.

I also found all of the details of how the Ninja hardware worked on this site. This last modification consisted of replacing the micrcontroller with an SX controller and changed the Ninja to be controlled over a serial link to a PC. It also involved a new protocol and several new capabilities. While I liked this approach, I wanted to control several Ninjas and the distance would just be too great for an RS-232 connection.

So let`s get started. In the shot on the left you can see the PCB, main processor, the 5 volt regulator under the mess of wiring, and the ribbon cables which supply the power signals to the servos located under the PCB. In the shot on the right you can see the RF receiver board which is responsible for receiving the RF signal and transmitting it to the main processor.

This board has 3 wires connecting it to the main board - the white and black wires which are +5V and Ground as well as the yellow wire which is the signal to the main processor. Since we are not using RF, we will remove this board and then design our new interface to fit in the same location using the same wires.

If we do this correctly, the processor will never know the difference. Before removing the board completely, I cut the wire to get a better look at the signal going to the Ninja processor. In order to see this, I used my Logic Analyzer from Saleae LLC. This is a great product at a great price and, if you`ve never used one before, it`s a great tool for understanding whats going on with your circuits and programming.

So when I hooked up the analyzer to the yellow signal wires, here`s what I got: My choice was to replace the RF board with my own board using an Atmel ATTiny2313 AVR controller. I`ve been using Atmel processors for a while now and am very pleased with their performance and, while I can program them in assembler, I usually choose Bascom-AVR.

This is a very nice Basic compiler and produces excellent and fast code. In order to make sure that I could replicate the Ninja protocol, I installed a Tiny2313 on my breadboard 🔗 External reference