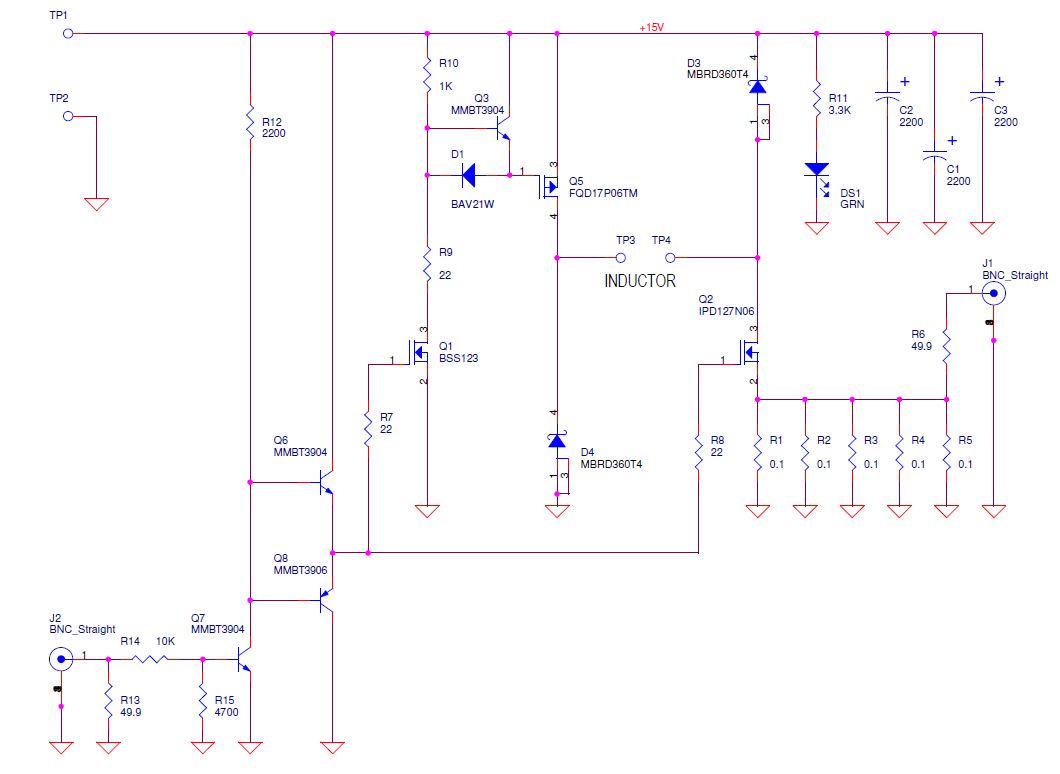

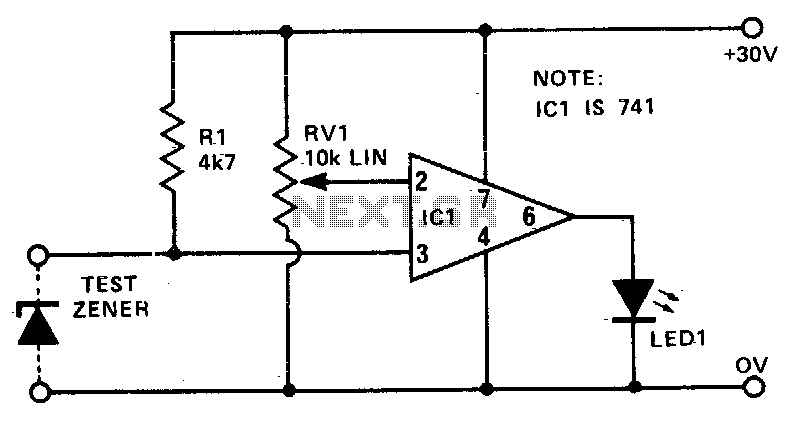

Zener tester

This circuit offers a cost-effective and dependable method for testing zener diodes. The variable resistor RV1 can be calibrated in volts, allowing the user to determine the zener voltage directly by observing when LED 1 begins to illuminate. At this point, the voltage at pins 2 and 3 will be nearly equal. The power supply voltage only needs to be equal to or greater than the zener voltage being tested. Additionally, for enhanced measurement accuracy, a precision potentiometer may be incorporated and calibrated.

The circuit consists of a basic configuration that includes a zener diode under test, a variable resistor RV1, an LED indicator, and a power supply. The zener diode is connected in reverse bias, allowing it to regulate the voltage when it reaches its breakdown voltage. The variable resistor RV1 is adjusted until the LED indicator lights up, signaling that the zener voltage has been reached.

To enhance the precision of the measurement, the circuit can be modified by integrating a precision potentiometer in place of or in parallel with RV1. This modification allows for finer adjustments and more accurate readings of the zener voltage. The power supply used in the circuit should be chosen carefully to ensure that it can provide a voltage that is sufficient for the zener diode under test, while also being within safe operating limits.

The design can be implemented on a breadboard for prototyping or on a printed circuit board (PCB) for a more permanent solution. Proper attention should be given to the connections and component placements to avoid errors in voltage readings. Furthermore, the circuit could be enhanced with additional features such as a digital voltmeter display for direct voltage readings or a microcontroller interface for automated testing procedures.

This simple yet effective circuit serves as a valuable tool for electronics enthusiasts and professionals alike, facilitating the testing and verification of zener diodes in various applications.This circuit provides a low cost and reliable method of testing zener diodes. RVl can be calibrated in volts, so that when LED 1 just lights, the voltage on pins 2 and 3 are nearly equal. Hence, the zener voltage can be read directly from the setting of RVl. The supply need only be as high a value as the zener itself For a more accurate measurement, a precision pot could be added and calibrated. 🔗 External reference

The circuit consists of a basic configuration that includes a zener diode under test, a variable resistor RV1, an LED indicator, and a power supply. The zener diode is connected in reverse bias, allowing it to regulate the voltage when it reaches its breakdown voltage. The variable resistor RV1 is adjusted until the LED indicator lights up, signaling that the zener voltage has been reached.

To enhance the precision of the measurement, the circuit can be modified by integrating a precision potentiometer in place of or in parallel with RV1. This modification allows for finer adjustments and more accurate readings of the zener voltage. The power supply used in the circuit should be chosen carefully to ensure that it can provide a voltage that is sufficient for the zener diode under test, while also being within safe operating limits.

The design can be implemented on a breadboard for prototyping or on a printed circuit board (PCB) for a more permanent solution. Proper attention should be given to the connections and component placements to avoid errors in voltage readings. Furthermore, the circuit could be enhanced with additional features such as a digital voltmeter display for direct voltage readings or a microcontroller interface for automated testing procedures.

This simple yet effective circuit serves as a valuable tool for electronics enthusiasts and professionals alike, facilitating the testing and verification of zener diodes in various applications.This circuit provides a low cost and reliable method of testing zener diodes. RVl can be calibrated in volts, so that when LED 1 just lights, the voltage on pins 2 and 3 are nearly equal. Hence, the zener voltage can be read directly from the setting of RVl. The supply need only be as high a value as the zener itself For a more accurate measurement, a precision pot could be added and calibrated. 🔗 External reference