Host stall after stall to auxiliary control circuit

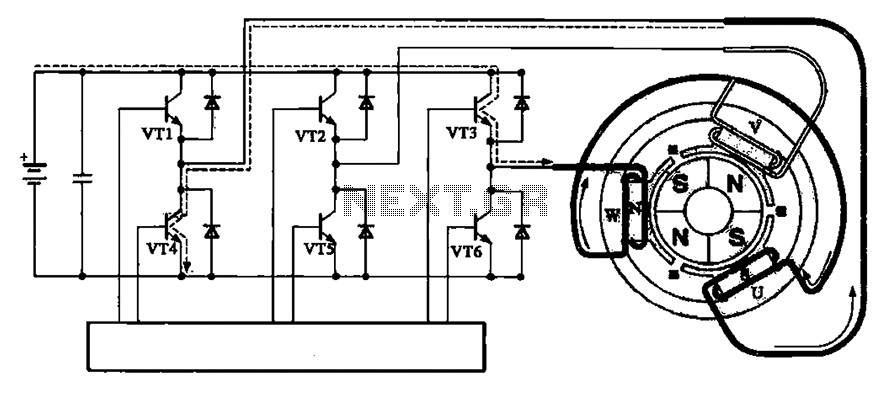

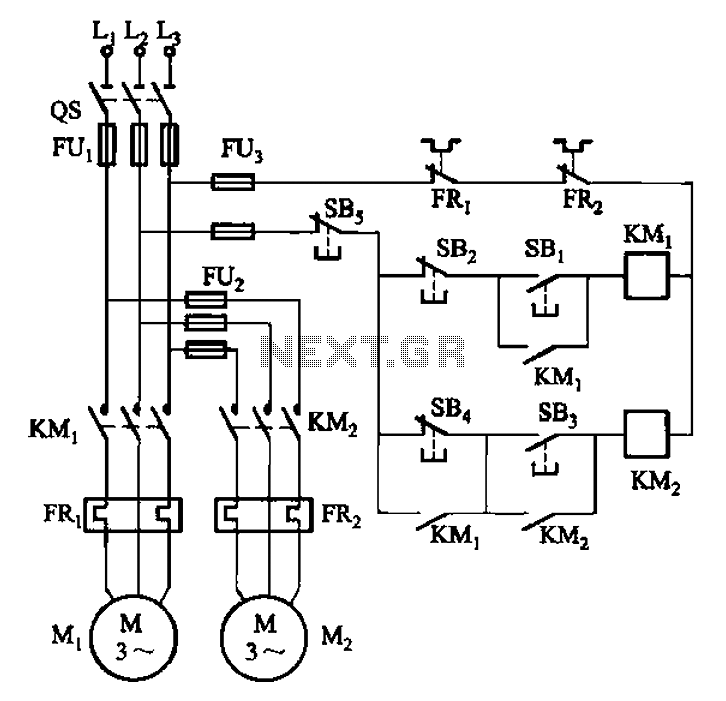

The circuit depicted in Figure 3-84 allows two electric motors to be started independently. The motors can only be activated after pressing the main stop button (SBz) to release contact KMi. Following this, the auxiliary stop button (SB4) can be pressed to stop motor M2. The emergency stop button (SBs) is available for simultaneous shutdown of both motors when necessary.

The circuit in question is designed to control the operation of two electric motors (M1 and M2) in a safe and efficient manner. It utilizes a series of control elements including start and stop buttons, relays, and contactors to manage the motors' operation.

The main components involved in this circuit include:

1. **Electric Motors (M1 and M2)**: These are the primary loads that the circuit controls. Each motor can be activated or deactivated independently.

2. **Main Stop Button (SBz)**: This button serves as a safety feature to ensure that both motors can be stopped quickly. When pressed, it releases the relay contact (KMi), allowing for safe operation of the motors.

3. **Auxiliary Stop Button (SB4)**: This button is specifically designed to stop motor M2 without affecting M1. It provides flexibility in operation, allowing for maintenance or control of individual motors.

4. **Emergency Stop Button (SBs)**: This button is critical for safety, as it can immediately cut power to both motors in emergency situations. It ensures that operators can respond quickly to any hazardous conditions.

5. **Relay Contact (KMi)**: This component is responsible for controlling the power supplied to the motors based on the state of the stop buttons. When the main stop button is pressed, the relay opens, interrupting the power flow.

The operational sequence begins with the pressing of the main stop button (SBz), which releases the relay contact (KMi). Following this, either motor can be started by activating their respective controls. To stop motor M2, the auxiliary stop button (SB4) is pressed, while motor M1 continues to operate. In situations where both motors need to be halted simultaneously, the emergency stop button (SBs) can be activated.

This circuit design emphasizes safety and operational flexibility, making it suitable for various industrial applications where independent motor control is essential. Proper labeling and circuit protection devices should be incorporated to enhance reliability and user safety. Circuit shown in Figure 3-84. Be seen by the two electric motors can be started separately. But only when you press Host (Ml) of the stop button SBz (after contact KMi release) , then press the auxiliary (Mz) stop button SB4, only marrow make M2 stop. SBs for the emergency stop button, when you need to shut down the two motors together, you can press the SBs.

The circuit in question is designed to control the operation of two electric motors (M1 and M2) in a safe and efficient manner. It utilizes a series of control elements including start and stop buttons, relays, and contactors to manage the motors' operation.

The main components involved in this circuit include:

1. **Electric Motors (M1 and M2)**: These are the primary loads that the circuit controls. Each motor can be activated or deactivated independently.

2. **Main Stop Button (SBz)**: This button serves as a safety feature to ensure that both motors can be stopped quickly. When pressed, it releases the relay contact (KMi), allowing for safe operation of the motors.

3. **Auxiliary Stop Button (SB4)**: This button is specifically designed to stop motor M2 without affecting M1. It provides flexibility in operation, allowing for maintenance or control of individual motors.

4. **Emergency Stop Button (SBs)**: This button is critical for safety, as it can immediately cut power to both motors in emergency situations. It ensures that operators can respond quickly to any hazardous conditions.

5. **Relay Contact (KMi)**: This component is responsible for controlling the power supplied to the motors based on the state of the stop buttons. When the main stop button is pressed, the relay opens, interrupting the power flow.

The operational sequence begins with the pressing of the main stop button (SBz), which releases the relay contact (KMi). Following this, either motor can be started by activating their respective controls. To stop motor M2, the auxiliary stop button (SB4) is pressed, while motor M1 continues to operate. In situations where both motors need to be halted simultaneously, the emergency stop button (SBs) can be activated.

This circuit design emphasizes safety and operational flexibility, making it suitable for various industrial applications where independent motor control is essential. Proper labeling and circuit protection devices should be incorporated to enhance reliability and user safety. Circuit shown in Figure 3-84. Be seen by the two electric motors can be started separately. But only when you press Host (Ml) of the stop button SBz (after contact KMi release) , then press the auxiliary (Mz) stop button SB4, only marrow make M2 stop. SBs for the emergency stop button, when you need to shut down the two motors together, you can press the SBs.