1200 to 6000A-10V three-phase thyristor power regulator circuit plating

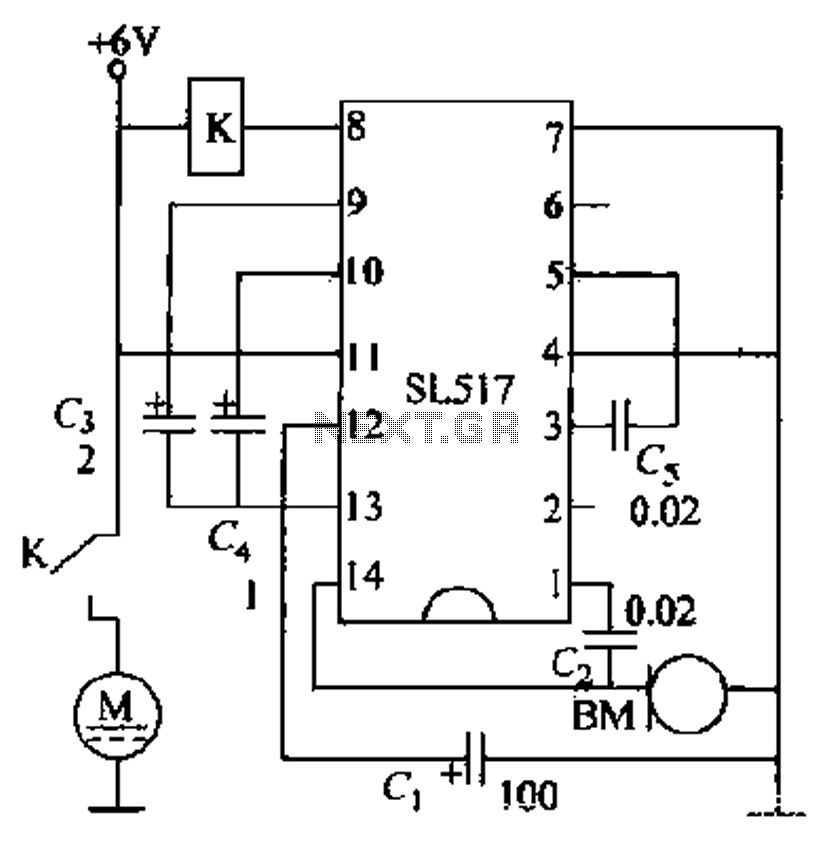

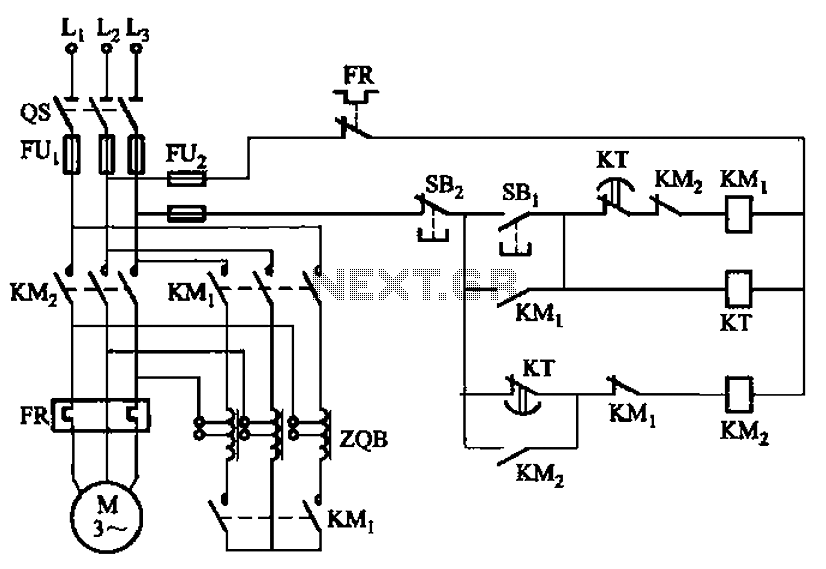

A three-phase thyristor power regulator circuit designed for plating applications, capable of handling currents from 1200A to 6000A at a voltage of 10V. The circuit comprises a main circuit, a trigger circuit, synchronous power components, and a voltage negative feedback circuit, along with protection circuits and other essential components. The basic circuit configuration resembles a specified figure. This design utilizes six rectifier diodes rated at 200A each to achieve an output of 1200A. For higher current demands, multiple rectifier diodes can be connected in parallel; for instance, using 48 rectifier diodes rated at 200A each allows for an output of 6000A, provided that other circuit parameters remain unchanged. A master adjustment potentiometer (RPi) is incorporated to enable the adjustment of cell voltage.

The three-phase thyristor power regulator circuit is engineered for industrial plating processes where precise control of current and voltage is critical. The main circuit is responsible for converting the input AC power into a regulated DC output, which is essential for electroplating applications. The thyristors serve as the primary switching elements, allowing for efficient control of the power delivered to the load.

The trigger circuit plays a vital role in controlling the firing angle of the thyristors, thereby regulating the output voltage and current. By adjusting the firing angle, the circuit can finely tune the output to meet specific plating requirements. The synchronous power components ensure that the thyristors operate in harmony with the AC input, maintaining system stability and performance.

Voltage negative feedback is implemented to monitor the output voltage continuously. This feedback loop enables the circuit to adjust the firing angle of the thyristors automatically, ensuring that the output voltage remains within desired limits despite variations in load or input conditions. Protection circuits are integrated to safeguard the system against overcurrent, overvoltage, and thermal overload conditions, enhancing the reliability and longevity of the power regulator.

For applications requiring higher current outputs, the circuit allows for the parallel configuration of rectifier diodes. This flexibility means that as demand increases, additional diodes can be added without necessitating a complete redesign of the circuit. The use of a master adjustment potentiometer (RPi) provides operators with the ability to fine-tune the cell voltage, accommodating various plating solutions and operational conditions.

Overall, this thyristor power regulator circuit is a robust solution for high-current applications, combining efficient power conversion with precise control mechanisms to meet the demanding requirements of industrial plating processes.1200 to 6000A-10V three-phase thyristor power regulator circuit plating It consists of a main circuit, trigger circuit, synchronous power, voltage negative feedback circuit and protection circuits and other components. The basic circuit configuration is similar to FIG. This circuit uses when six rectifier diodes 200A can output 1200A, higher current output requirements, can be a plurality of rectifying diodes in parallel, such as the use of 48 200A rectifier diodes, output 6000A (circuit elements other parameters unchanged). Master adjust potentiometer RPi, you can change the size of the cell voltage.

The three-phase thyristor power regulator circuit is engineered for industrial plating processes where precise control of current and voltage is critical. The main circuit is responsible for converting the input AC power into a regulated DC output, which is essential for electroplating applications. The thyristors serve as the primary switching elements, allowing for efficient control of the power delivered to the load.

The trigger circuit plays a vital role in controlling the firing angle of the thyristors, thereby regulating the output voltage and current. By adjusting the firing angle, the circuit can finely tune the output to meet specific plating requirements. The synchronous power components ensure that the thyristors operate in harmony with the AC input, maintaining system stability and performance.

Voltage negative feedback is implemented to monitor the output voltage continuously. This feedback loop enables the circuit to adjust the firing angle of the thyristors automatically, ensuring that the output voltage remains within desired limits despite variations in load or input conditions. Protection circuits are integrated to safeguard the system against overcurrent, overvoltage, and thermal overload conditions, enhancing the reliability and longevity of the power regulator.

For applications requiring higher current outputs, the circuit allows for the parallel configuration of rectifier diodes. This flexibility means that as demand increases, additional diodes can be added without necessitating a complete redesign of the circuit. The use of a master adjustment potentiometer (RPi) provides operators with the ability to fine-tune the cell voltage, accommodating various plating solutions and operational conditions.

Overall, this thyristor power regulator circuit is a robust solution for high-current applications, combining efficient power conversion with precise control mechanisms to meet the demanding requirements of industrial plating processes.1200 to 6000A-10V three-phase thyristor power regulator circuit plating It consists of a main circuit, trigger circuit, synchronous power, voltage negative feedback circuit and protection circuits and other components. The basic circuit configuration is similar to FIG. This circuit uses when six rectifier diodes 200A can output 1200A, higher current output requirements, can be a plurality of rectifying diodes in parallel, such as the use of 48 200A rectifier diodes, output 6000A (circuit elements other parameters unchanged). Master adjust potentiometer RPi, you can change the size of the cell voltage.